| OPERATION | |||||

|

|

|

|

|

|

|

|

|

|

| USER DEFINED PARAMETERS |

|

|

|

|

|

|

|

| |

|

|

|

|

|

| |

|

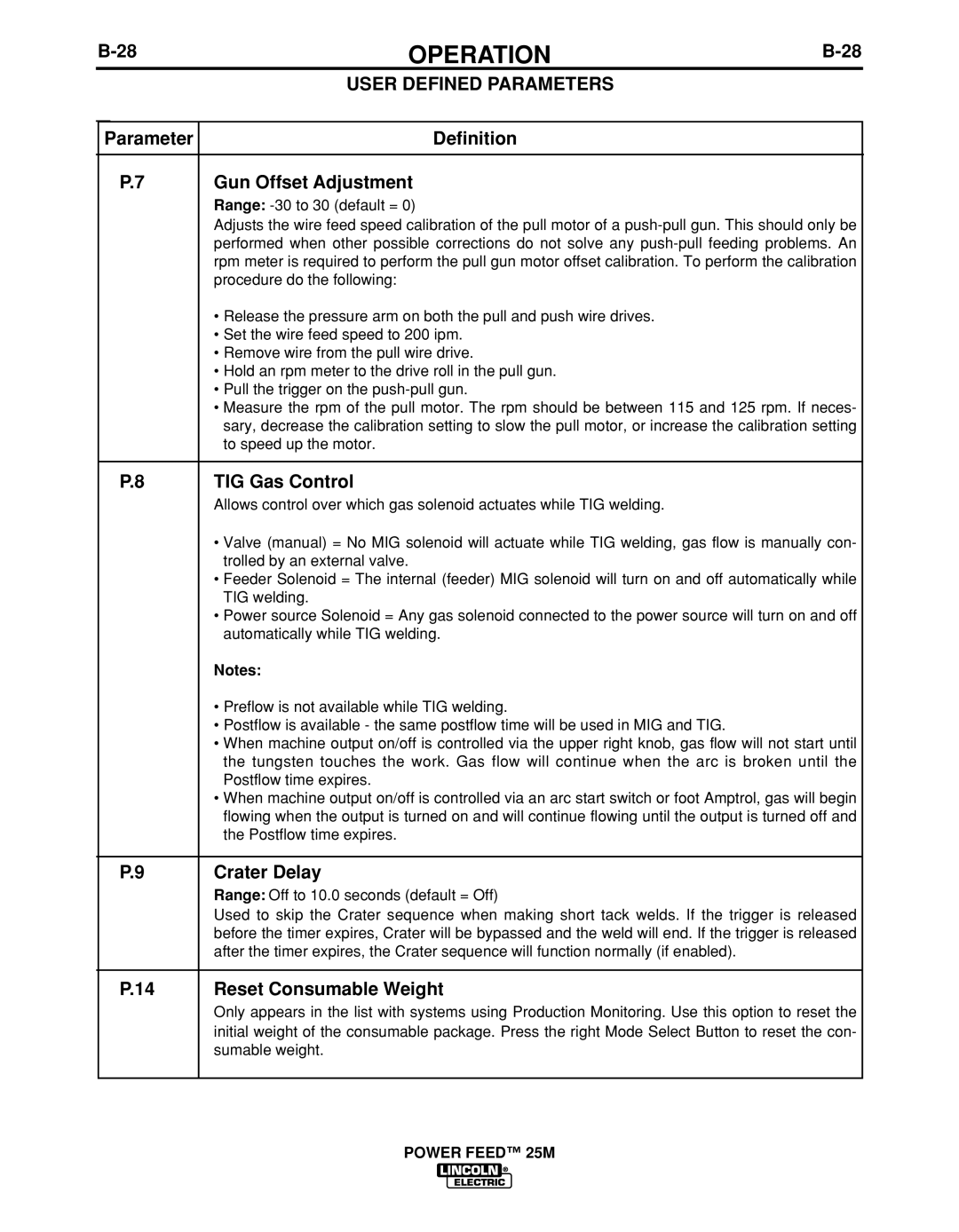

| Parameter | Definition |

|

| |

|

|

|

|

|

| |

|

| P.7 | Gun Offset Adjustment |

|

| |

|

|

|

| Range: |

|

|

|

|

|

| Adjusts the wire feed speed calibration of the pull motor of a |

| |

|

|

|

| performed when other possible corrections do not solve any |

| |

|

|

|

| rpm meter is required to perform the pull gun motor offset calibration. To perform the calibration |

| |

|

|

|

| procedure do the following: |

|

|

|

|

|

| • Release the pressure arm on both the pull and push wire drives. |

|

|

|

|

|

| • Set the wire feed speed to 200 ipm. |

|

|

|

|

|

| • Remove wire from the pull wire drive. |

|

|

|

|

|

| • Hold an rpm meter to the drive roll in the pull gun. |

|

|

|

|

|

| • Pull the trigger on the |

|

|

|

|

|

| • Measure the rpm of the pull motor. The rpm should be between 115 and 125 rpm. If neces- |

| |

|

|

|

| sary, decrease the calibration setting to slow the pull motor, or increase the calibration setting |

| |

|

|

|

| to speed up the motor. |

|

|

|

|

|

|

|

| |

|

| P.8 | TIG Gas Control |

|

| |

|

|

|

| Allows control over which gas solenoid actuates while TIG welding. |

|

|

|

|

|

| • Valve (manual) = No MIG solenoid will actuate while TIG welding, gas flow is manually con- |

| |

|

|

|

| trolled by an external valve. |

|

|

|

|

|

| • Feeder Solenoid = The internal (feeder) MIG solenoid will turn on and off automatically while |

| |

|

|

|

| TIG welding. |

|

|

|

|

|

| • Power source Solenoid = Any gas solenoid connected to the power source will turn on and off |

| |

|

|

|

| automatically while TIG welding. |

|

|

|

|

|

| Notes: |

|

|

|

|

|

| • Preflow is not available while TIG welding. |

|

|

|

|

|

| • Postflow is available - the same postflow time will be used in MIG and TIG. |

|

|

|

|

|

| • When machine output on/off is controlled via the upper right knob, gas flow will not start until |

| |

|

|

|

| the tungsten touches the work. Gas flow will continue when the arc is broken until the |

| |

|

|

|

| Postflow time expires. |

|

|

|

|

|

| • When machine output on/off is controlled via an arc start switch or foot Amptrol, gas will begin |

| |

|

|

|

| flowing when the output is turned on and will continue flowing until the output is turned off and |

| |

|

|

|

| the Postflow time expires. |

|

|

|

|

|

|

|

| |

|

| P.9 | Crater Delay |

|

| |

|

|

|

| Range: Off to 10.0 seconds (default = Off) |

|

|

|

|

|

| Used to skip the Crater sequence when making short tack welds. If the trigger is released |

| |

|

|

|

| before the timer expires, Crater will be bypassed and the weld will end. If the trigger is released |

| |

|

|

|

| after the timer expires, the Crater sequence will function normally (if enabled). |

|

|

|

|

|

|

|

| |

|

| P.14 | Reset Consumable Weight |

|

| |

|

|

|

| Only appears in the list with systems using Production Monitoring. Use this option to reset the |

| |

|

|

|

| initial weight of the consumable package. Press the right Mode Select Button to reset the con- |

| |

|

|

|

| sumable weight. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|