OPERATION | ||

|

|

|

COLD FEED/GAS PURGE SWITCH

Cold Feed and Gas Purge are com- bined into a single spring centered tog- gle switch.

To activate Cold Feeding, hold the ![]()

![]() switch in the UP position. The wire drive

switch in the UP position. The wire drive

will feed electrode but neither the power source nor the gas solenoid will be energized. Adjust the speed of cold feeding by rotating the WFS knob. Cold feed- ing, or "cold inching" the electrode is useful for thread- ing the electrode through the gun.

Hold with toggle switch in the DOWN position to acti- vate Gas Purge and let the shielding gas flow. The gas solenoid valve will energize but neither the power source output nor the drive motor will be turned on. The Gas Purge switch is useful for setting the proper flow rate of shielding gas. Flow meters should always be adjusted while the shielding gas is flowing.

LIGHT SWITCH

ON

Turn the internal light switch ON to illuminate the inside of the POWER

PRESSURE ARM ADJUSTMENT

ELECTRIC SHOCK can kill.

•Turn the input power OFF at the weld- ing power source before installation or changing drive rolls and/or guides.

•Do not touch electrically live parts.

•When inching with the gun trigger, electrode and drive mechanism are "hot" to work and ground and could remain energized several sec- onds after the gun trigger is released.

•Do not operate with covers, panels or guards removed or open

•Only qualified personnel should perform mainte- nance work.

The pressure arm controls the amount of force the drive rolls exert on the wire. Proper adjustment of pressure arm gives the best welding performance.

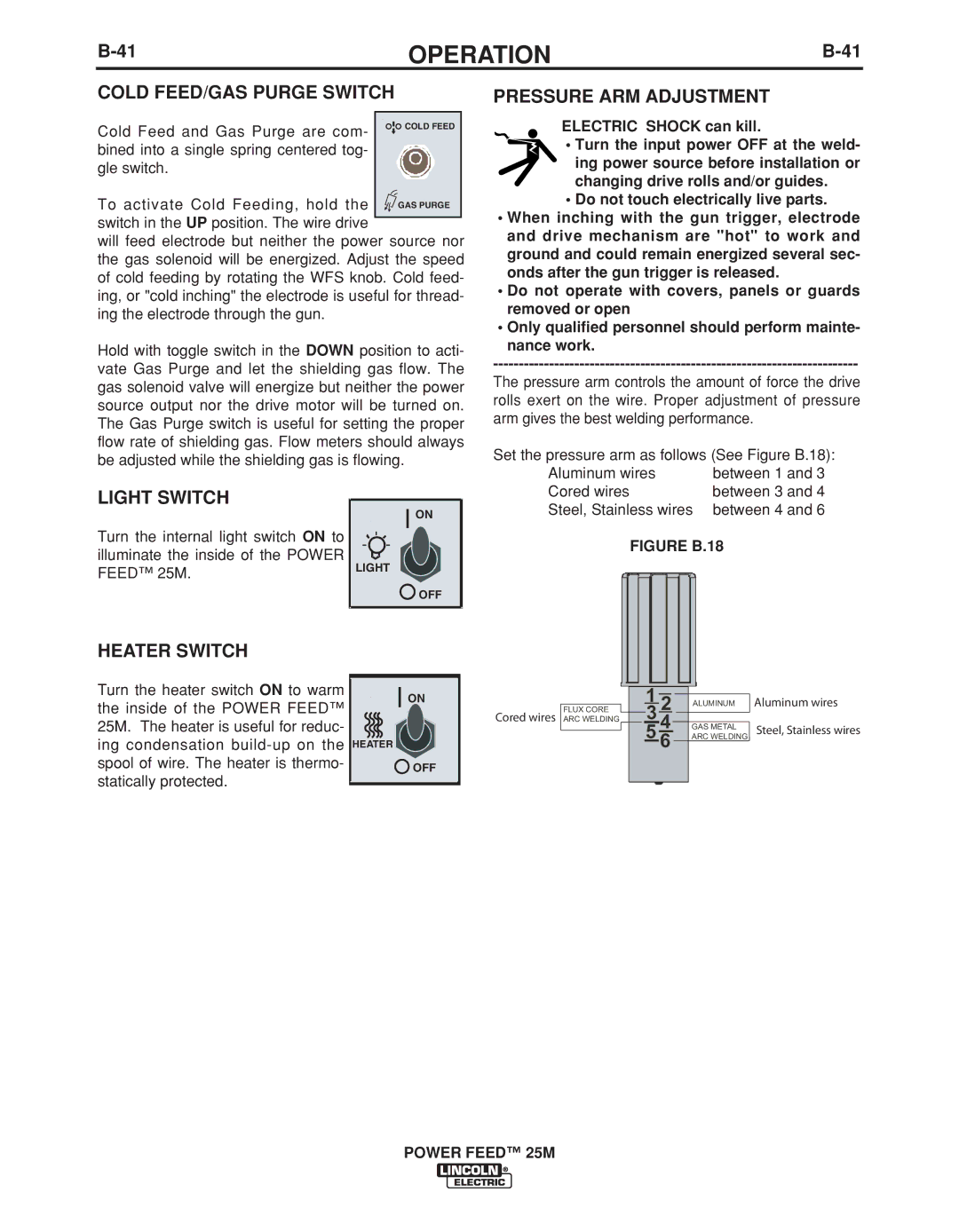

Set the pressure arm as follows (See Figure B.18):

Aluminum wires | between 1 and 3 |

Cored wires | between 3 and 4 |

Steel, Stainless wires | between 4 and 6 |

FIGURE B.18

FEED™ 25M. | LIGHT |

|

![]() OFF

OFF

HEATER SWITCH |

| |

|

|

|

Turn the heater switch ON to warm |

| ON |

| ||

the inside of the POWER FEED™ |

| |

|

| |

25M. The heater is useful for reduc- |

|

|

ing condensation | HEATER |

|

spool of wire. The heater is thermo- |

| OFF |

statically protected. |

|

|

|

| |

Cored wires

FLUX CORE ARC WELDING

1 | 2 | ALUMINUM |

3 | 4 | GAS METAL |

5 | 6 | ARC WELDING |

Aluminum wires

Steel, Stainless wires