| OPERATION | ||||

|

|

|

|

|

|

|

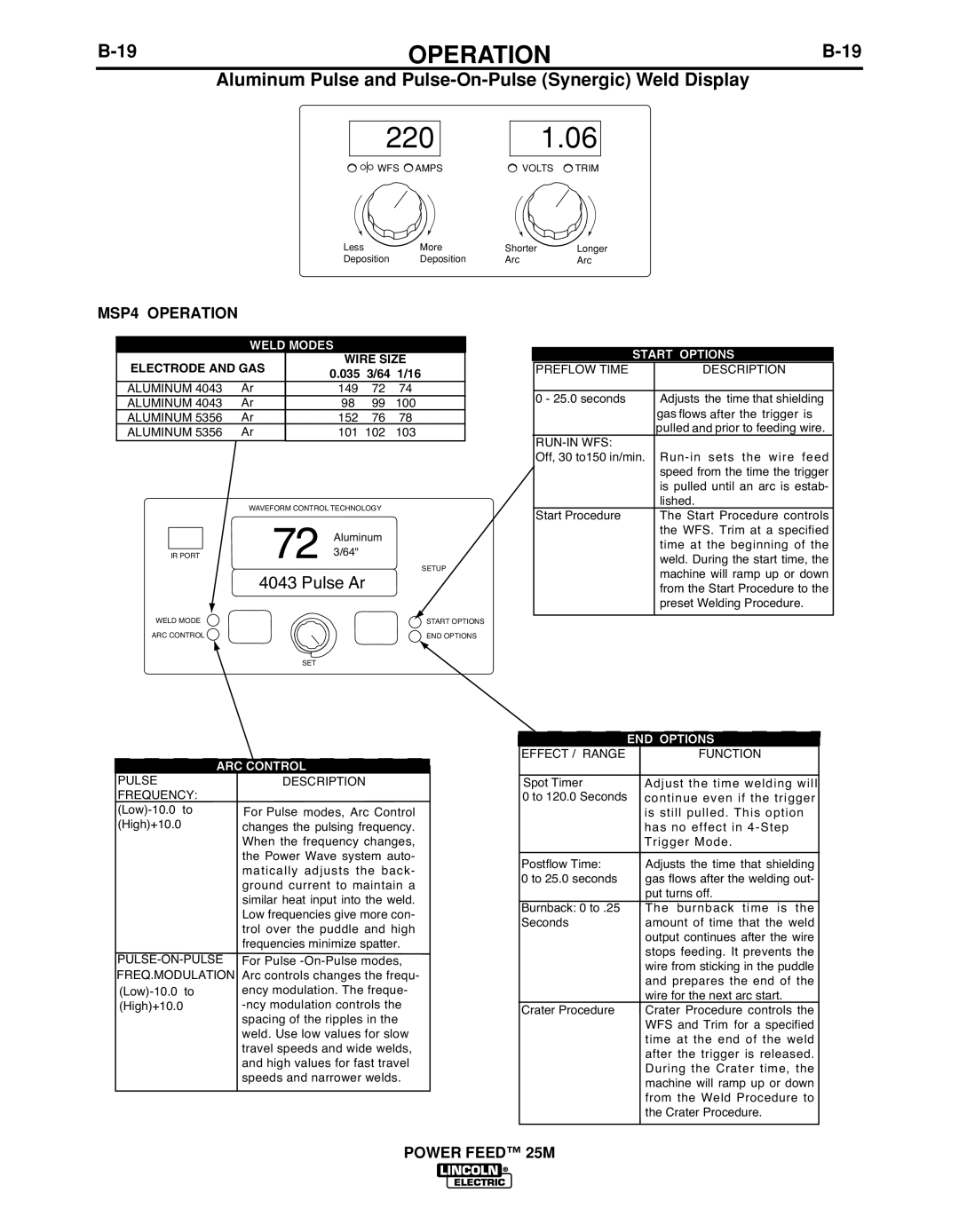

| Aluminum Pulse and |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

220

1.06

WFS AMPS | VOLTS TRIM |

Less | More | Shorter | Longer |

Deposition | Deposition | Arc | Arc |

MSP4 OPERATION

WELD MODES

ELECTRODE AND GAS | WIRE SIZE | ||||

0.035 | 3/64 | 1/16 | |||

|

| ||||

ALUMINUM 4043 | Ar | 149 | 72 | 74 | |

ALUMINUM 4043 | Ar | 98 | 99 | 100 | |

ALUMINUM 5356 | Ar | 152 | 76 | 78 | |

ALUMINUM 5356 | Ar | 101 | 102 | 103 | |

WAVEFORM CONTROL TECHNOLOGY

| 72 | Aluminum |

|

IR PORT | 3/64" |

| |

| SETUP | ||

| 4043 Pulse Ar |

| |

WELD MODE |

|

| START OPTIONS |

ARC CONTROL |

|

| END OPTIONS |

SET

ARC CONTROL |

| |

PULSE | DESCRIPTION | |

FREQUENCY: |

|

|

For Pulse | modes, A rc Control | |

(High)+10.0 | changes the pulsing frequency. | |

| When the frequency changes, | |

| the Power Wave system auto- | |

| matically | adjusts the back - |

| ground current t o maintain a | |

| similar heat input into the weld. | |

| Low frequencies give more con- | |

| trol over the puddle and high | |

frequencies minimize spatter. | ||

For Pulse | ||

FREQ.MODULATION | Arc controls changes the frequ- | |

ency modulation. The freque- | ||

(High)+10.0 | ||

| spacing of the ripples in the | |

| weld. Use low values for slow | |

| travel speeds and wide welds, | |

| and high values for fast travel | |

| speeds and narrower welds. | |

START OPTIONS

|

|

| ||

PREFLOW TIME | DESCRIPTION |

| ||

|

| |||

0 - 25.0 seconds | Adjusts the time that shielding | |||

| gas flows after | the trigger | is | |

| pulled and prior to feeding wire. | |||

| the wire | feed | ||

Off, 30 to150 in/min. | ||||

| speed from the time the trigger | |||

| is pulled until an arc is estab- | |||

| lished. |

|

|

|

Start Procedure | The Start Procedure | control s | ||

| the WFS. Trim a t a specified | |||

| time at t he beginning | of t he | ||

| weld. During the start time, the | |||

| machine will ramp up or down | |||

| from the Start Procedure to the | |||

| preset Welding Procedure. | |||

END OPTIONS

|

|

|

|

| |||||

Spot Timer |

| Adjust the time welding will |

|

| |||||

0 to 120.0 Seconds |

| continue even if the trigger |

|

| |||||

|

| is still pulled. This option |

|

|

| ||||

|

| has no effect in |

|

|

| ||||

|

| Trigger Mode. |

|

|

|

|

| ||

Postflow Time: |

| Adjusts the time that shielding |

| ||||||

0 to 25.0 seconds |

| gas flows after the welding out- |

| ||||||

|

| put turns off. |

|

|

|

|

| ||

Burnback: 0 to .25 |

| The | burnback | time | is t he |

| |||

Seconds | amount of time that the weld |

| |||||||

|

| output continues after the wire |

| ||||||

|

| stops feeding. It prevents the |

| ||||||

|

| wire from sticking in the puddle |

| ||||||

|

| and | prepares the end | of the |

| ||||

|

| wire for the next arc start. |

|

| |||||

Crater Procedure | Crater P rocedure | controls | the |

| |||||

|

| WFS and Trim for a | specified |

| |||||

|

| time | at | the end | of t he wel d |

| |||

|

| after | the trigger | is | released. |

| |||

|

| During | the Crater | time, | t he |

| |||

|

| machine will ramp up or down |

| ||||||

|

| from | the Weld Procedure | to |

| ||||

|

| the Crater Procedure. |

|

|

| ||||

|

|

|

|

|

|

|

|

|

|