Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

INSTALLATION | ||

|

|

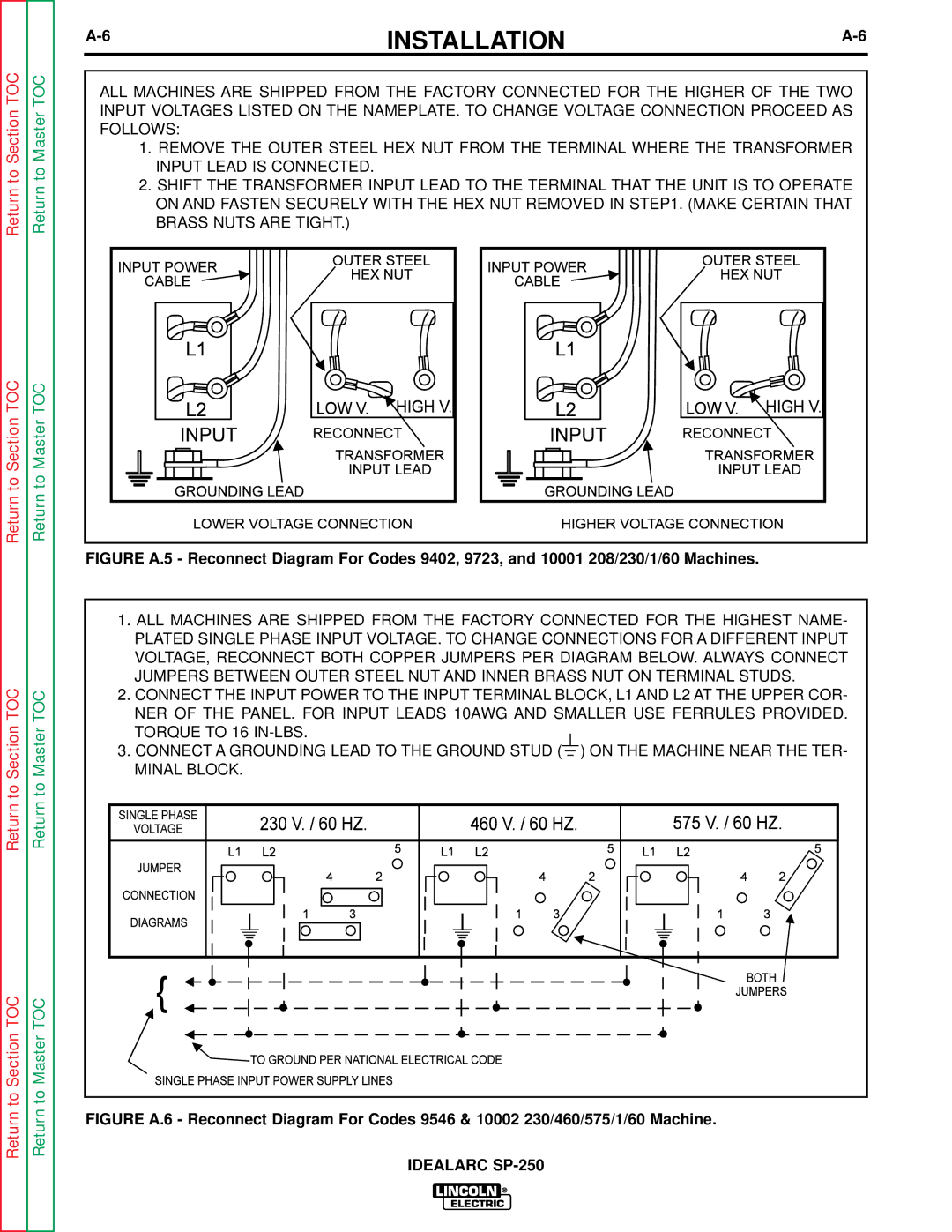

ALL MACHINES ARE SHIPPED FROM THE FACTORY CONNECTED FOR THE HIGHER OF THE TWO INPUT VOLTAGES LISTED ON THE NAMEPLATE. TO CHANGE VOLTAGE CONNECTION PROCEED AS FOLLOWS:

1.REMOVE THE OUTER STEEL HEX NUT FROM THE TERMINAL WHERE THE TRANSFORMER INPUT LEAD IS CONNECTED.

2.SHIFT THE TRANSFORMER INPUT LEAD TO THE TERMINAL THAT THE UNIT IS TO OPERATE ON AND FASTEN SECURELY WITH THE HEX NUT REMOVED IN STEP1. (MAKE CERTAIN THAT BRASS NUTS ARE TIGHT.)

FIGURE A.5 - Reconnect Diagram For Codes 9402, 9723, and 10001 208/230/1/60 Machines.

1.ALL MACHINES ARE SHIPPED FROM THE FACTORY CONNECTED FOR THE HIGHEST NAME- PLATED SINGLE PHASE INPUT VOLTAGE. TO CHANGE CONNECTIONS FOR A DIFFERENT INPUT VOLTAGE, RECONNECT BOTH COPPER JUMPERS PER DIAGRAM BELOW. ALWAYS CONNECT JUMPERS BETWEEN OUTER STEEL NUT AND INNER BRASS NUT ON TERMINAL STUDS.

2.CONNECT THE INPUT POWER TO THE INPUT TERMINAL BLOCK, L1 AND L2 AT THE UPPER COR- NER OF THE PANEL. FOR INPUT LEADS 10AWG AND SMALLER USE FERRULES PROVIDED. TORQUE TO 16

3.CONNECT A GROUNDING LEAD TO THE GROUND STUD (![]() ) ON THE MACHINE NEAR THE TER- MINAL BLOCK.

) ON THE MACHINE NEAR THE TER- MINAL BLOCK.