Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR |

|

|

|

|

| ||||||||

|

|

|

|

|

|

| |||||||

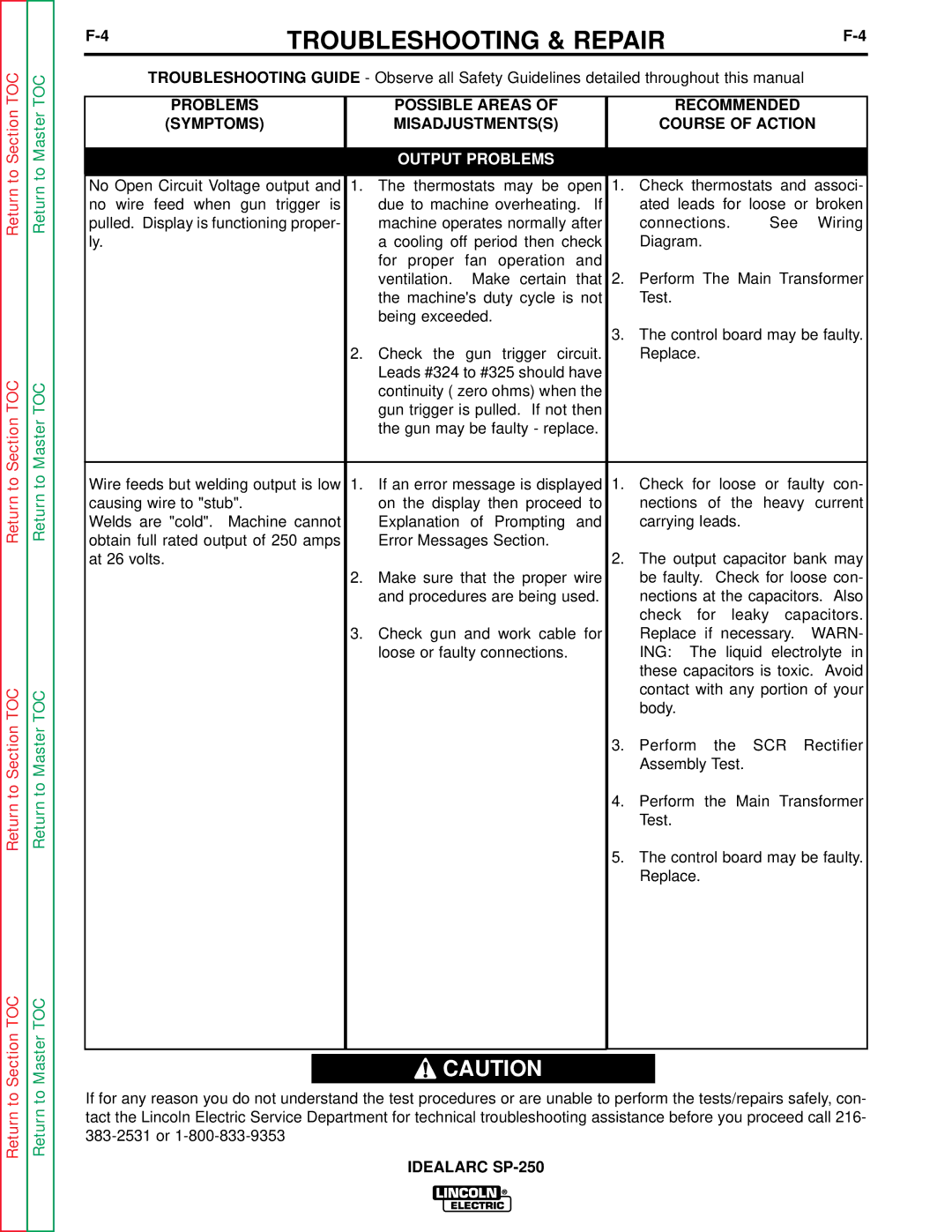

TROUBLESHOOTING GUIDE - Observe all Safety Guidelines detailed throughout this manual | |||||||||||||

|

|

|

|

|

|

|

| ||||||

PROBLEMS |

|

| POSSIBLE AREAS OF |

|

| RECOMMENDED |

| ||||||

(SYMPTOMS) |

|

| MISADJUSTMENTS(S) |

|

| COURSE OF ACTION | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| OUTPUT PROBLEMS |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No Open Circuit Voltage output and | 1. | The thermostats may be open 1. | Check thermostats and associ- | ||||||||||

no wire feed when gun trigger is |

| due to machine overheating. If |

| ated leads for loose or broken | |||||||||

pulled. Display is functioning proper- |

| machine operates normally after |

| connections. |

| See | Wiring | ||||||

ly. |

|

| a cooling off period then check |

| Diagram. |

|

|

|

|

| |||

|

|

| for proper fan operation and |

|

|

|

|

|

|

|

| ||

|

|

| ventilation. | Make certain that | 2. | Perform The | Main Transformer | ||||||

|

|

| the machine's duty cycle is not |

| Test. |

|

|

|

|

|

| ||

|

|

| being exceeded. |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| 3. | The control board may be faulty. | ||||||

|

| 2. | Check the gun trigger circuit. |

| Replace. |

|

|

|

|

| |||

|

|

| Leads #324 to #325 should have |

|

|

|

|

|

|

|

| ||

|

|

| continuity ( zero ohms) when the |

|

|

|

|

|

|

|

| ||

|

|

| gun trigger is pulled. If not then |

|

|

|

|

|

|

|

| ||

|

|

| the gun may be faulty - replace. |

|

|

|

|

|

|

|

| ||

|

|

|

|

| |||||||||

Wire feeds but welding output is low | 1. | If an error message is displayed | 1. | Check for loose or faulty con- | |||||||||

causing wire to "stub". |

|

| on the display then proceed to |

| nections of the heavy current | ||||||||

Welds are "cold". Machine cannot |

| Explanation | of Prompting and |

| carrying leads. |

|

| ||||||

obtain full rated output of 250 amps |

| Error Messages Section. |

|

|

|

|

|

|

|

| |||

at 26 volts. |

|

|

|

|

| 2. | The output capacitor bank may | ||||||

|

| 2. | Make sure that the proper wire |

| be faulty. | Check for loose con- | |||||||

|

|

| and procedures are being used. |

| nections at the capacitors. Also | ||||||||

|

|

|

|

|

|

| check | for | leaky | capacitors. | |||

|

| 3. | Check gun and work cable for |

| Replace if necessary. | WARN- | |||||||

|

|

| loose or faulty connections. |

| ING: | The | liquid | electrolyte in | |||||

|

|

|

|

|

|

| these capacitors is toxic. Avoid | ||||||

|

|

|

|

|

|

| contact with any portion of your | ||||||

|

|

|

|

|

|

| body. |

|

|

|

|

|

|

|

|

|

|

|

| 3. | Perform | the | SCR | Rectifier | |||

|

|

|

|

|

|

| Assembly Test. |

|

| ||||

4. Perform the Main Transformer

Test.

5. The control board may be faulty. Replace.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, con- tact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed call 216-