|

|

| OPERATION | ||||

|

|

|

|

| |||

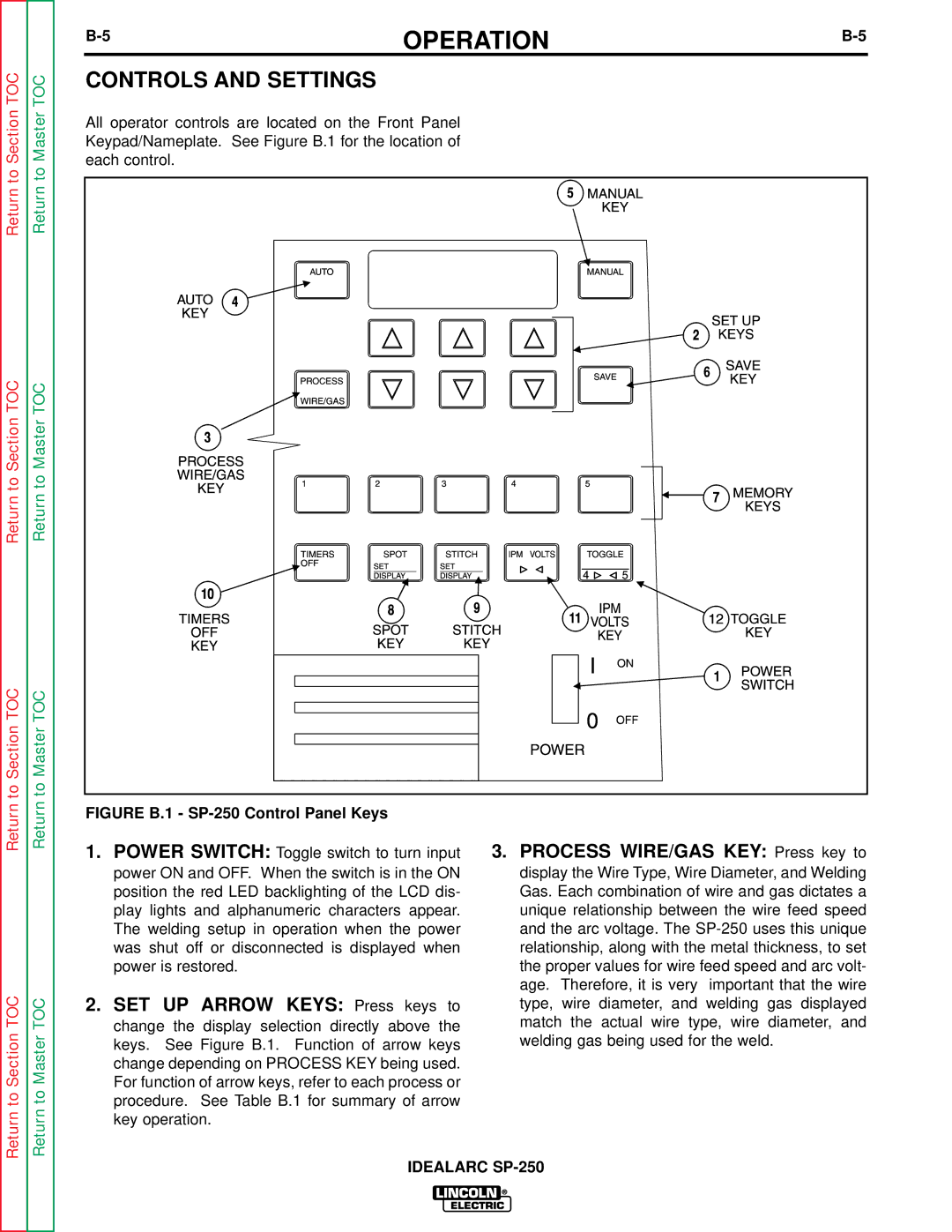

TOC | TOC | CONTROLS AND SETTINGS |

|

| |||

|

|

|

|

| |||

Section | Master | All operator controls are located on the Front Panel |

|

| |||

Keypad/Nameplate. See Figure B.1 for the location of |

|

| |||||

each control. |

|

|

| ||||

Return to | Return to |

|

|

| |||

|

|

|

|

| |||

Return to Section TOC | Return to Master TOC |

|

|

|

|

| |

to Section TOC | to Master TOC |

|

|

|

|

| |

Return | Return | FIGURE B.1 - |

|

| |||

1. POWER SWITCH: Toggle switch to turn input | 3. PROCESS WIRE/GAS KEY: Press key to | ||||||

|

| ||||||

|

| power ON and OFF. When the switch is in the ON | display the Wire Type, Wire Diameter, and Welding | ||||

|

| position the red LED backlighting of the LCD dis- | Gas. Each combination of wire and gas dictates a | ||||

|

| play lights and alphanumeric characters appear. | unique relationship between the wire feed speed | ||||

|

| The welding setup in operation when the power | and the arc voltage. The | ||||

|

| was shut off or disconnected is displayed when | relationship, along with the metal thickness, to set | ||||

|

| power is restored. |

| the proper values for wire feed speed and arc volt- | |||

TOC |

|

|

|

| age. Therefore, it is very | important that the wire | |

TOC | 2. SET UP ARROW KEYS: Press keys to | type, wire diameter, and welding gas displayed | |||||

change the display selection directly above the | match the actual wire type, wire diameter, and | ||||||

Section | Master | keys. | See Figure B.1. | Function of arrow keys | welding gas being used for the weld. | ||

change depending on PROCESS KEY being used. |

|

| |||||

For function of arrow keys, refer to each process or |

|

| |||||

to | to | procedure. See Table B.1 for summary of arrow |

|

| |||

Return | Return | key operation. |

|

|

| ||

|

|

|

|

| |||