|

|

|

| OPERATION |

|

| ||||

|

|

|

|

|

|

|

| |||

Return to Section TOC | Return to Master TOC |

|

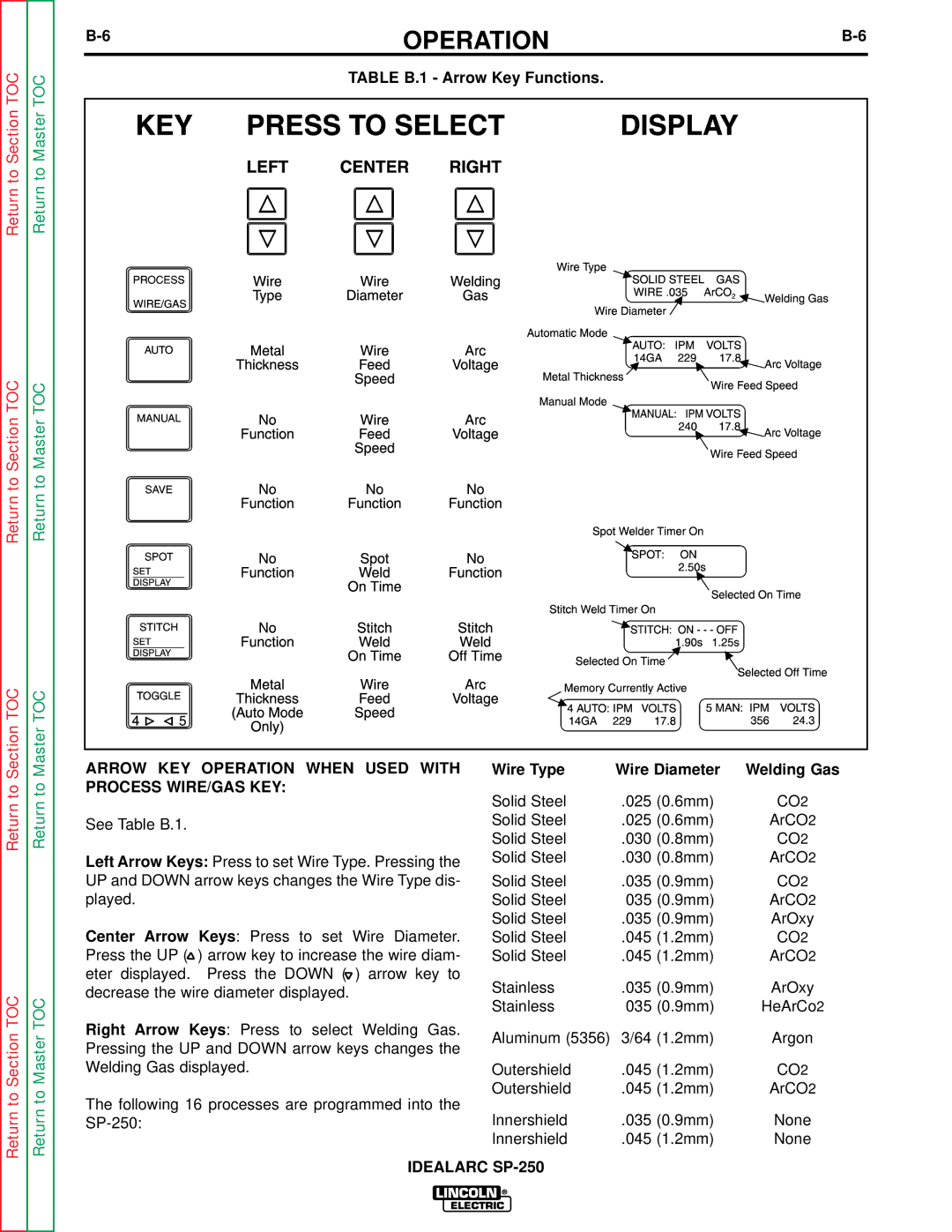

| TABLE B.1 - Arrow Key Functions. |

|

|

| |||

|

|

|

|

|

|

|

| |||

Return to Section TOC | Return to Master TOC |

|

|

|

|

|

|

|

| |

Section TOC | Master TOC | ARROW KEY OPERATION | WHEN | USED WITH | Wire Type | Wire Diameter | Welding Gas | |||

to | to | PROCESS WIRE/GAS KEY: |

|

| Solid Steel | .025 | (0.6mm) | CO2 | ||

Return | Return |

|

|

|

| |||||

See Table B.1. |

|

|

| Solid Steel | .025 | (0.6mm) | ArCO2 | |||

|

|

|

| Solid Steel | .030 | (0.8mm) | CO2 | |||

Left Arrow Keys: Press to set Wire Type. Pressing the | Solid Steel | .030 | (0.8mm) | ArCO2 | ||||||

|

| |||||||||

|

| UP and DOWN arrow keys changes the Wire Type dis- | Solid Steel | .035 | (0.9mm) | CO2 | ||||

|

| played. |

|

|

| Solid Steel | 035 | (0.9mm) | ArCO2 | |

|

| Center Arrow Keys: Press to set Wire Diameter. | Solid Steel | .035 | (0.9mm) | ArOxy | ||||

|

| Solid Steel | .045 | (1.2mm) | CO2 | |||||

|

| Press the UP ( | ) arrow key to increase the wire diam- | Solid Steel | .045 | (1.2mm) | ArCO2 | |||

|

| eter displayed. | Press the DOWN ( ) arrow key to | Stainless | .035 | (0.9mm) | ArOxy | |||

TOC | TOC | decrease the wire diameter displayed. |

| |||||||

| Stainless | 035 | (0.9mm) | HeArCo2 | ||||||

|

|

|

| |||||||

Right Arrow Keys: Press to | select | Welding Gas. | Aluminum (5356) | 3/64 (1.2mm) | Argon | |||||

Section | Master | |||||||||

Pressing the UP and DOWN arrow keys changes the | ||||||||||

|

|

|

| |||||||

Welding Gas displayed. |

|

| Outershield | .045 | (1.2mm) | CO2 | ||||

|

|

|

| Outershield | .045 | (1.2mm) | ArCO2 | |||

to | to | The following 16 processes are programmed into the | ||||||||

|

|

|

| |||||||

Return | Return | Innershield | .035 | (0.9mm) | None | |||||

|

|

| ||||||||

|

|

|

| Innershield | .045 | (1.2mm) | None | |||

|

|

|

|

|

|

|

| |||