TOC

TOC

TROUBLESHOOTING & REPAIR | |

|

SCR OUTPUT RECTIFIER REMOVAL

Return to Section

Return to Section TOC

Return to Master

Return to Master TOC

PROCEDURE

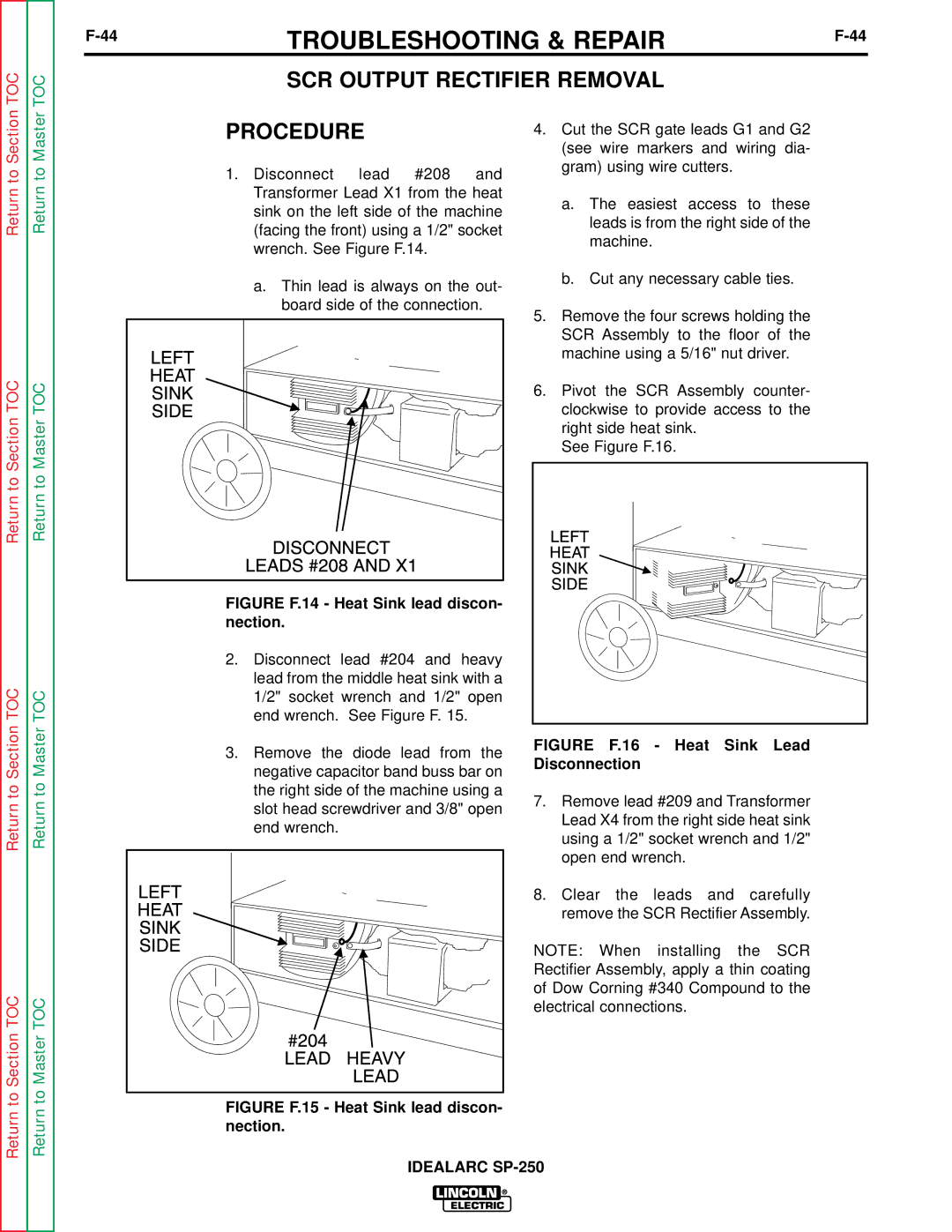

1. Disconnect lead #208 and Transformer Lead X1 from the heat sink on the left side of the machine (facing the front) using a 1/2" socket wrench. See Figure F.14.

a.Thin lead is always on the out- board side of the connection.

4.Cut the SCR gate leads G1 and G2 (see wire markers and wiring dia- gram) using wire cutters.

a.The easiest access to these leads is from the right side of the machine.

b.Cut any necessary cable ties.

5.Remove the four screws holding the SCR Assembly to the floor of the machine using a 5/16" nut driver.

6.Pivot the SCR Assembly counter- clockwise to provide access to the right side heat sink.

See Figure F.16.

Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

FIGURE F.14 - Heat Sink lead discon- nection.

2.Disconnect lead #204 and heavy lead from the middle heat sink with a 1/2" socket wrench and 1/2" open end wrench. See Figure F. 15.

3.Remove the diode lead from the negative capacitor band buss bar on the right side of the machine using a slot head screwdriver and 3/8" open end wrench.

FIGURE F.16 - Heat Sink Lead Disconnection

7.Remove lead #209 and Transformer Lead X4 from the right side heat sink using a 1/2" socket wrench and 1/2" open end wrench.

8.Clear the leads and carefully remove the SCR Rectifier Assembly.

NOTE: When installing the SCR Rectifier Assembly, apply a thin coating of Dow Corning #340 Compound to the electrical connections.

Return

Return