OPERATION | ||

|

|

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

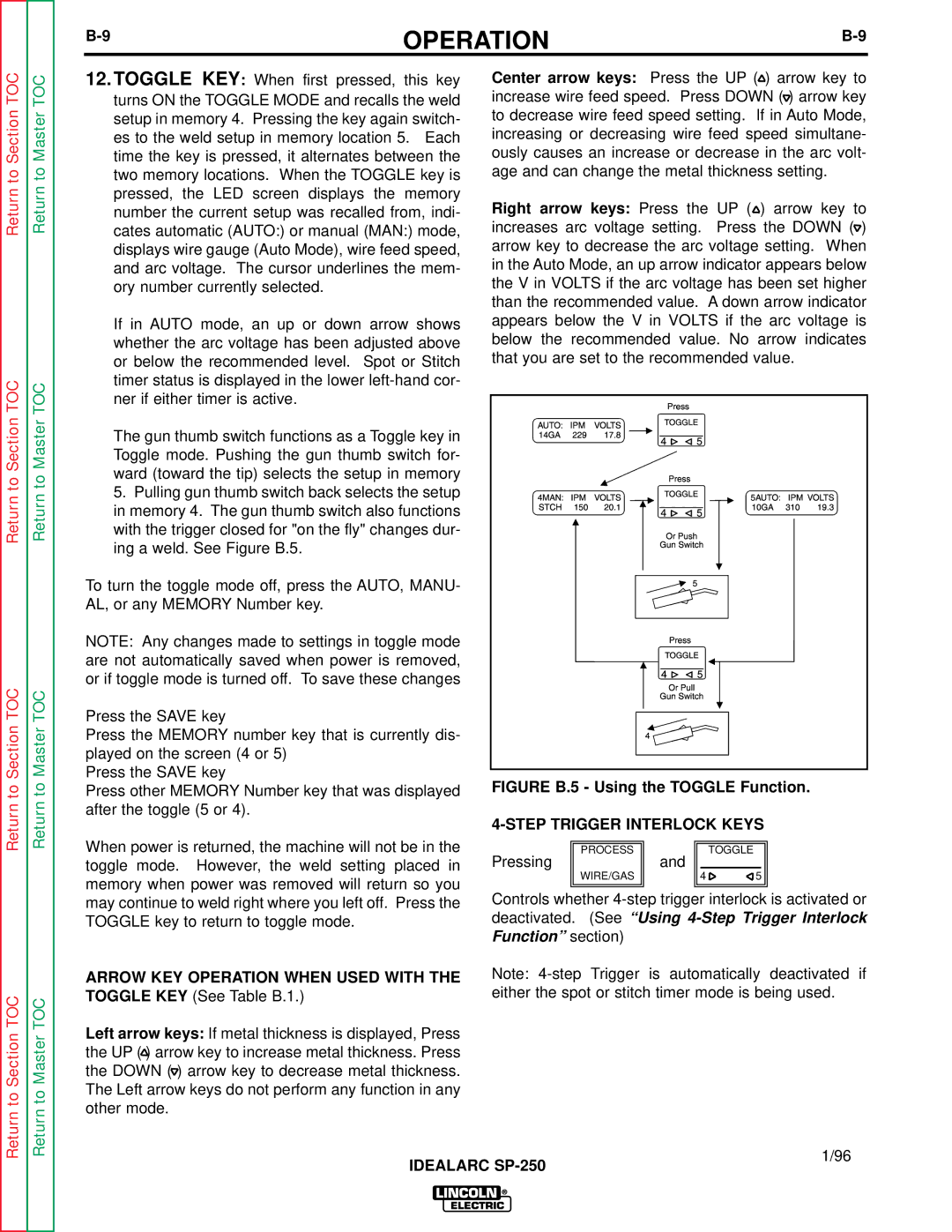

12.TOGGLE KEY: When first pressed, this key turns ON the TOGGLE MODE and recalls the weld setup in memory 4. Pressing the key again switch- es to the weld setup in memory location 5. Each time the key is pressed, it alternates between the two memory locations. When the TOGGLE key is pressed, the LED screen displays the memory number the current setup was recalled from, indi- cates automatic (AUTO:) or manual (MAN:) mode, displays wire gauge (Auto Mode), wire feed speed, and arc voltage. The cursor underlines the mem- ory number currently selected.

If in AUTO mode, an up or down arrow shows whether the arc voltage has been adjusted above or below the recommended level. Spot or Stitch timer status is displayed in the lower

The gun thumb switch functions as a Toggle key in Toggle mode. Pushing the gun thumb switch for- ward (toward the tip) selects the setup in memory

5.Pulling gun thumb switch back selects the setup in memory 4. The gun thumb switch also functions with the trigger closed for "on the fly" changes dur- ing a weld. See Figure B.5.

To turn the toggle mode off, press the AUTO, MANU- AL, or any MEMORY Number key.

NOTE: Any changes made to settings in toggle mode are not automatically saved when power is removed, or if toggle mode is turned off. To save these changes

Press the SAVE key

Press the MEMORY number key that is currently dis- played on the screen (4 or 5)

Press the SAVE key

Press other MEMORY Number key that was displayed after the toggle (5 or 4).

When power is returned, the machine will not be in the toggle mode. However, the weld setting placed in memory when power was removed will return so you may continue to weld right where you left off. Press the TOGGLE key to return to toggle mode.

ARROW KEY OPERATION WHEN USED WITH THE TOGGLE KEY (See Table B.1.)

Left arrow keys: If metal thickness is displayed, Press the UP (![]() ) arrow key to increase metal thickness. Press the DOWN (

) arrow key to increase metal thickness. Press the DOWN (![]() ) arrow key to decrease metal thickness. The Left arrow keys do not perform any function in any other mode.

) arrow key to decrease metal thickness. The Left arrow keys do not perform any function in any other mode.

Center arrow keys: Press the UP (![]() ) arrow key to increase wire feed speed. Press DOWN (

) arrow key to increase wire feed speed. Press DOWN (![]() ) arrow key to decrease wire feed speed setting. If in Auto Mode, increasing or decreasing wire feed speed simultane- ously causes an increase or decrease in the arc volt- age and can change the metal thickness setting.

) arrow key to decrease wire feed speed setting. If in Auto Mode, increasing or decreasing wire feed speed simultane- ously causes an increase or decrease in the arc volt- age and can change the metal thickness setting.

Right arrow keys: Press the UP (![]() ) arrow key to increases arc voltage setting. Press the DOWN (

) arrow key to increases arc voltage setting. Press the DOWN (![]() ) arrow key to decrease the arc voltage setting. When in the Auto Mode, an up arrow indicator appears below the V in VOLTS if the arc voltage has been set higher than the recommended value. A down arrow indicator appears below the V in VOLTS if the arc voltage is below the recommended value. No arrow indicates that you are set to the recommended value.

) arrow key to decrease the arc voltage setting. When in the Auto Mode, an up arrow indicator appears below the V in VOLTS if the arc voltage has been set higher than the recommended value. A down arrow indicator appears below the V in VOLTS if the arc voltage is below the recommended value. No arrow indicates that you are set to the recommended value.

FIGURE B.5 - Using the TOGGLE Function.

4-STEP TRIGGER INTERLOCK KEYS

Pressing | PROCESS | and |

|

| TOGGLE | |

WIRE/GAS |

|

|

|

| ||

|

| 4 | 5 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Controls whether

Note:

IDEALARC SP-250

1/96