OPERATION | ||

|

|

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

LOADING THE WIRE REEL

To mount a

1.Pull the

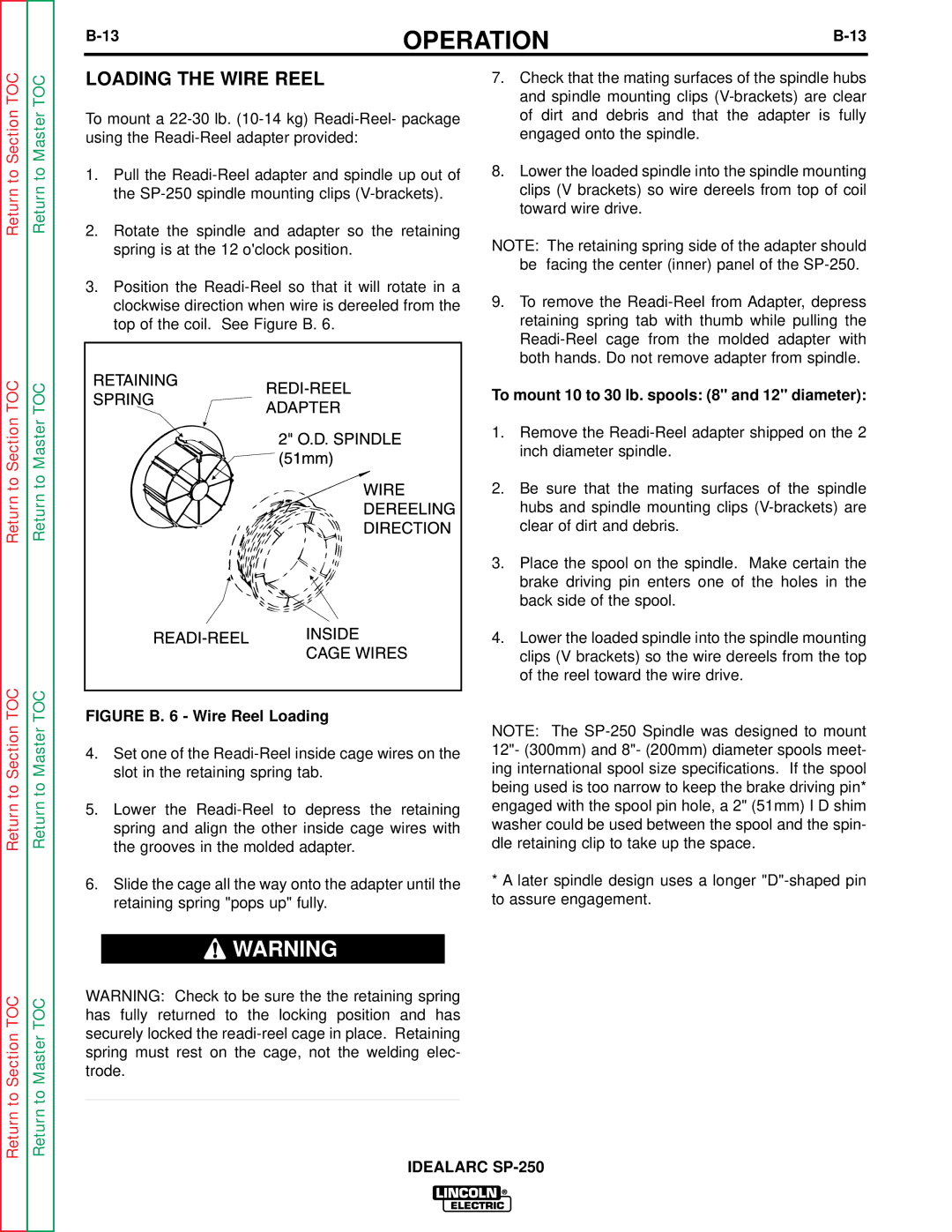

2.Rotate the spindle and adapter so the retaining spring is at the 12 o'clock position.

3.Position the

7.Check that the mating surfaces of the spindle hubs and spindle mounting clips

8.Lower the loaded spindle into the spindle mounting clips (V brackets) so wire dereels from top of coil toward wire drive.

NOTE: The retaining spring side of the adapter should be facing the center (inner) panel of the

9.To remove the

To mount 10 to 30 lb. spools: (8" and 12" diameter):

1.Remove the

2.Be sure that the mating surfaces of the spindle hubs and spindle mounting clips

3.Place the spool on the spindle. Make certain the brake driving pin enters one of the holes in the back side of the spool.

4.Lower the loaded spindle into the spindle mounting clips (V brackets) so the wire dereels from the top of the reel toward the wire drive.

Return to Master TOC

FIGURE B. 6 - Wire Reel Loading

4.Set one of the

5.Lower the

6.Slide the cage all the way onto the adapter until the retaining spring "pops up" fully.

NOTE: The

*A later spindle design uses a longer

Return to Master TOC

![]() WARNING

WARNING

WARNING: Check to be sure the the retaining spring has fully returned to the locking position and has securely locked the

____________________________________