Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

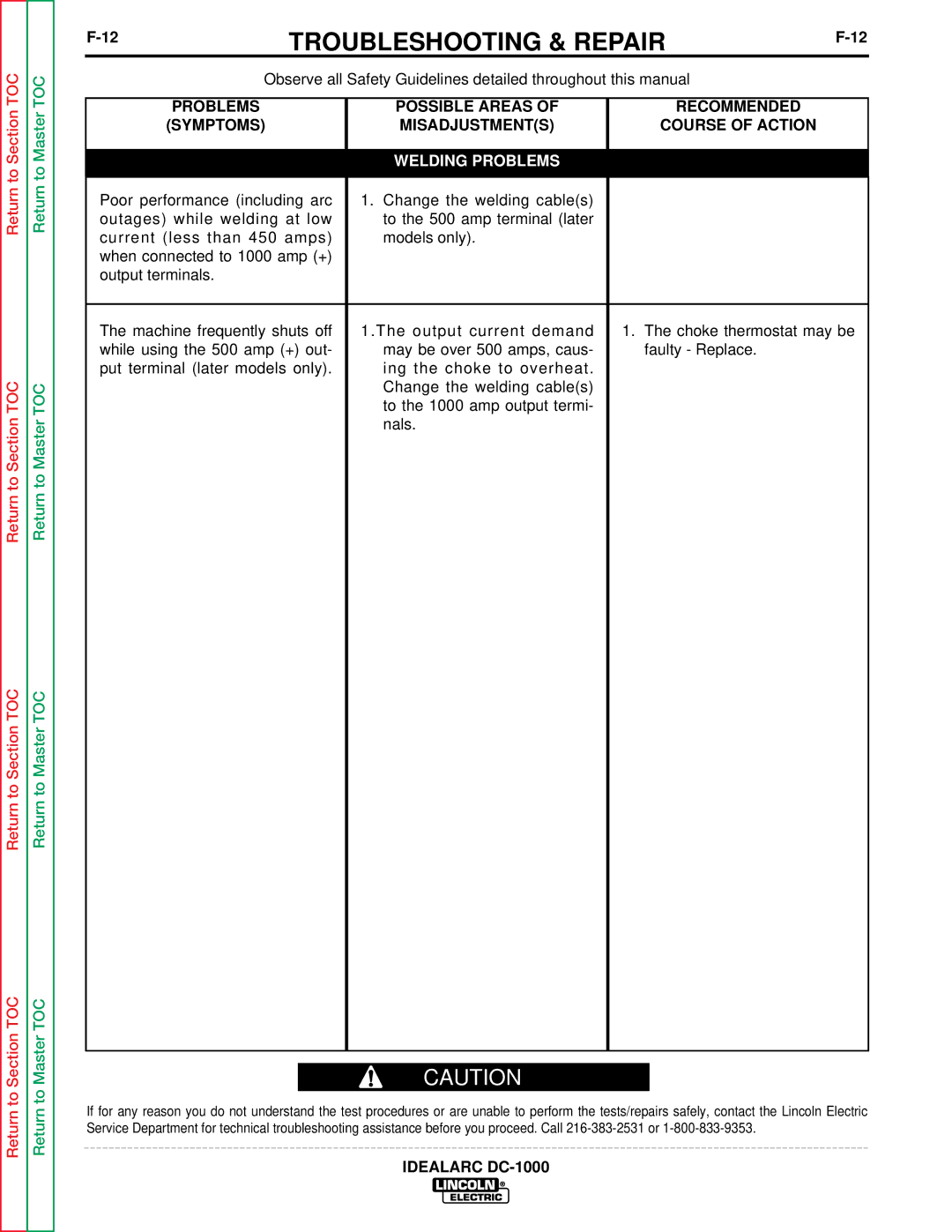

TROUBLESHOOTING & REPAIR | ||||

|

| |||

| Observe all Safety Guidelines detailed throughout this manual |

| ||

|

|

|

|

|

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

|

| (SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

|

|

|

|

|

|

|

| WELDING PROBLEMS |

|

|

|

|

|

| |

Poor performance (including arc | 1. Change the welding cable(s) |

|

| |

outages) while welding at low | to the 500 amp terminal (later |

|

| |

current (less than 450 amps) | models only). |

|

| |

when connected to 1000 amp (+) |

|

|

| |

output terminals. |

|

|

| |

|

|

| ||

The machine frequently shuts off | 1.The output current demand | 1. The choke thermostat may be | ||

while using the 500 amp (+) out- | may be over 500 amps, caus- | faulty - Replace. |

| |

put terminal (later models only). | ing the choke to overheat. |

|

| |

|

| Change the welding cable(s) |

|

|

|

| to the 1000 amp output termi- |

|

|

|

| nals. |

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call