ACCESSORIES | ||

|

|

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

d.Tape the #21 lead to work cable for ease of use.

6.Connect the welding cables as shown in Figure C.1.

NOTE: Welding cables must be of proper capacity for the current and duty cycle for immediate and future applications.

NOTE: The connection diagram shown in Figure C.1 shows the electrode connected for positive polarity. To change polarity:

a.Set the IDEALARC

b.Move the electrode cable to the Negative

c.Move the work cable to the Positive (+) output terminal.

d.Set the IDEALARC

e.Reverse the leads at the back of the ammeter and voltmeter on the wire feeder automatic control box.

CONNECTING THE NA-5 TO THE IDEALARC DC-1000

NOTE: For optimum performance, use the

1.Disconnect main AC input power to the IDE- ALARC

2.Set the IDEALARC

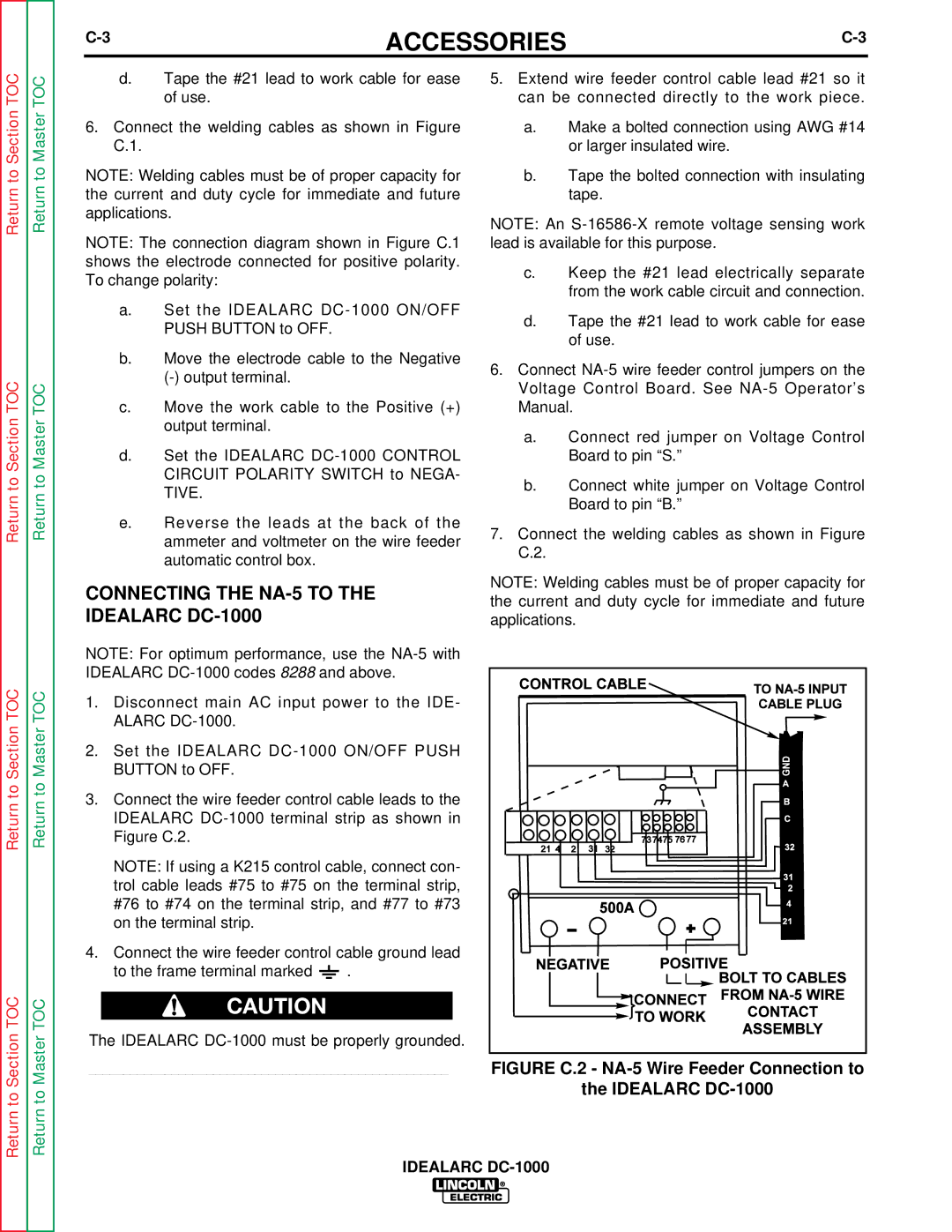

3.Connect the wire feeder control cable leads to the IDEALARC

NOTE: If using a K215 control cable, connect con- trol cable leads #75 to #75 on the terminal strip, #76 to #74 on the terminal strip, and #77 to #73 on the terminal strip.

4.Connect the wire feeder control cable ground lead

to the frame terminal marked ![]() .

.

CAUTION

The IDEALARC

____________________________________________________

5.Extend wire feeder control cable lead #21 so it can be connected directly to the work piece.

a.Make a bolted connection using AWG #14 or larger insulated wire.

b.Tape the bolted connection with insulating tape.

NOTE: An

c.Keep the #21 lead electrically separate from the work cable circuit and connection.

d.Tape the #21 lead to work cable for ease of use.

6.Connect

a.Connect red jumper on Voltage Control Board to pin “S.”

b.Connect white jumper on Voltage Control Board to pin “B.”

7.Connect the welding cables as shown in Figure C.2.

NOTE: Welding cables must be of proper capacity for the current and duty cycle for immediate and future applications.