TOC

TOC

TROUBLESHOOTING & REPAIR | ||

|

|

CONTROL BOARD TEST

Return to Section

Return to Section TOC

Return to Section TOC

Return to Master

Return to Master TOC

Return to Master TOC

IF LED 2 does not light when #2 and #4 are jumpered together.

1.Check for the presence of open cir- cuit voltage at the weld output ter- minals (27 to 75 VDC in constant voltage mode, 75 VDC in constant current mode).

a.If open circuit voltage IS present at the output termi- nals, then check for open circuit voltage from lead #222

b.If open circuit voltage is NOT present at the Control Board, then check leads #222 and #215 and associ- ated wiring for loose or faulty connections. See wiring diagram. Remove main supply power to the

2.Test for continuity (zero ohms) from the output shunt to lead #215 at plug J2 on the Control Board.

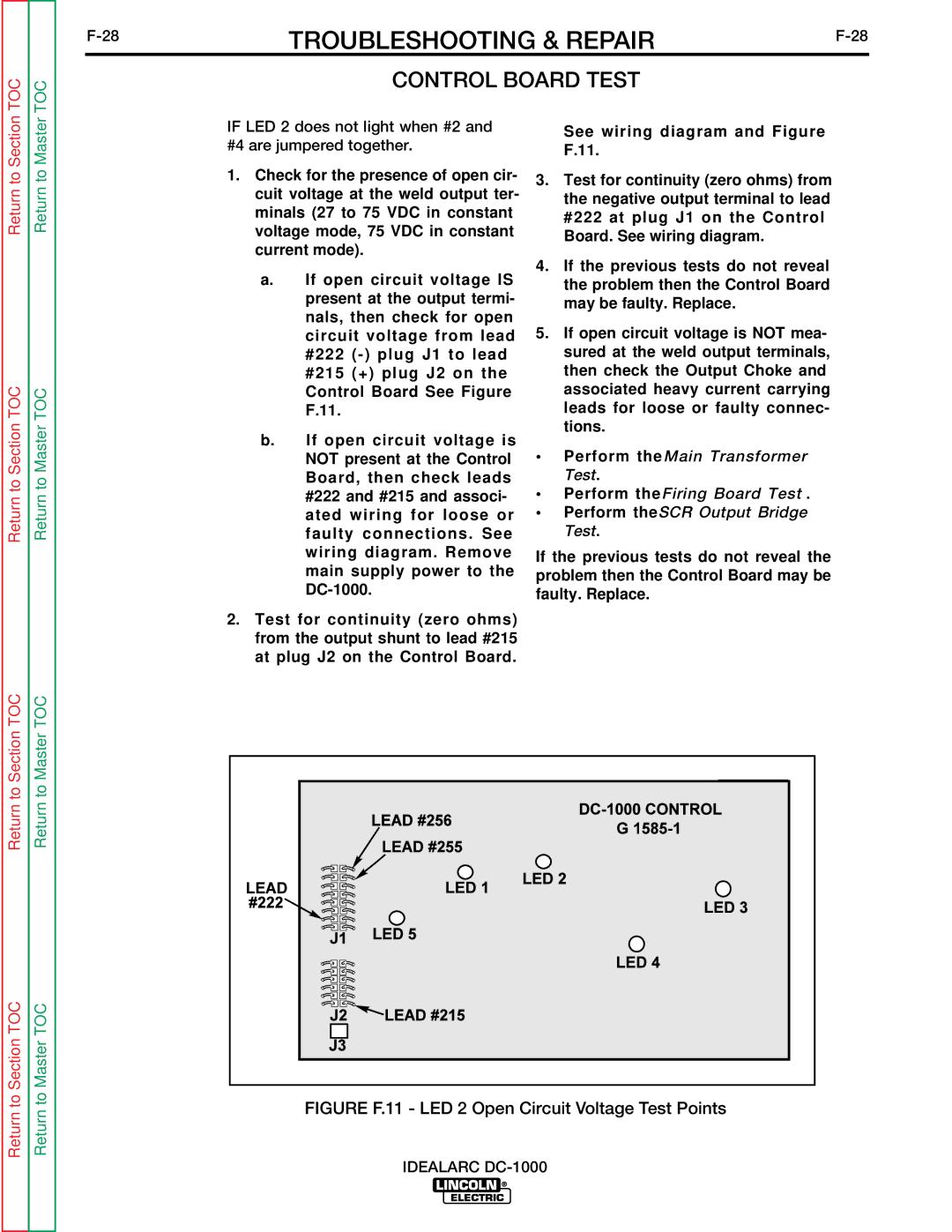

See wiring diagram and Figure F.11.

3.Test for continuity (zero ohms) from the negative output terminal to lead #222 at plug J1 on the Control Board. See wiring diagram.

4.If the previous tests do not reveal the problem then the Control Board may be faulty. Replace.

5.If open circuit voltage is NOT mea- sured at the weld output terminals, then check the Output Choke and associated heavy current carrying leads for loose or faulty connec- tions.

•Perform the Main Transformer Test.

•Perform the Firing Board Test.

•Perform the SCR Output Bridge

Test.

If the previous tests do not reveal the problem then the Control Board may be faulty. Replace.

Return to Section TOC

Return to Master TOC