|

|

|

| INSTALLATION | |||||||||||||

|

|

|

|

|

|

| |||||||||||

TOC | TOC | OUTPUT CONNECTIONS | 3. Connect electrode lead to the desired terminal | ||||||||||||||

|

|

|

|

| (positive or negative) and tighten the output ter- | ||||||||||||

|

|

|

|

|

|

|

| ||||||||||

Section | Master | See Table A.1 for recommended IDEALARC | minal nut with a wrench. | ||||||||||||||

cable sizes for combined length of electrode and work | 4. Connect the second work lead to the other out- | ||||||||||||||||

|

|

| |||||||||||||||

|

|

| cables. |

|

|

| |||||||||||

|

|

|

|

|

| put terminal (positive if negative is attached and | |||||||||||

to | to |

|

|

|

|

| |||||||||||

|

| TABLE A.1 |

|

| vice versa) following steps 2 and 3. | ||||||||||||

Return | Return |

|

|

|

|

| |||||||||||

|

|

|

|

|

| AUXILIARY POWER | |||||||||||

| Suggested Copper Cable Sizes - 100% Duty Cycle |

| |||||||||||||||

|

|

| Combined Lengths of Electrodes and Work Cables |

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| This machine supplies the 115 volt, AC power need- | |||||||||

|

|

| Amperes |

| Length | Cable Size |

| ||||||||||

|

|

|

|

| ed for operating wire feeding equipment. The power | ||||||||||||

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

| ||||||||||

|

|

| 1000 |

| 0 - 250 ft. |

| is available from terminals #31 and #32 on the termi- | ||||||||||

|

|

|

|

| (76.2m) | (3 x 85.0 mm2) |

| nal strip. An 8 amp slow blow fuse on the machine | |||||||||

|

|

|

|

|

|

|

| control panel protects the auxiliary power from | |||||||||

|

|

| CONNECT ELECTRODE AND WORK | ||||||||||||||

|

|

| excessive overloads. The circuit has a 1000 volt- | ||||||||||||||

TOC | TOC | LEADS TO OUTPUT TERMINALS | ampere rating. | ||||||||||||||

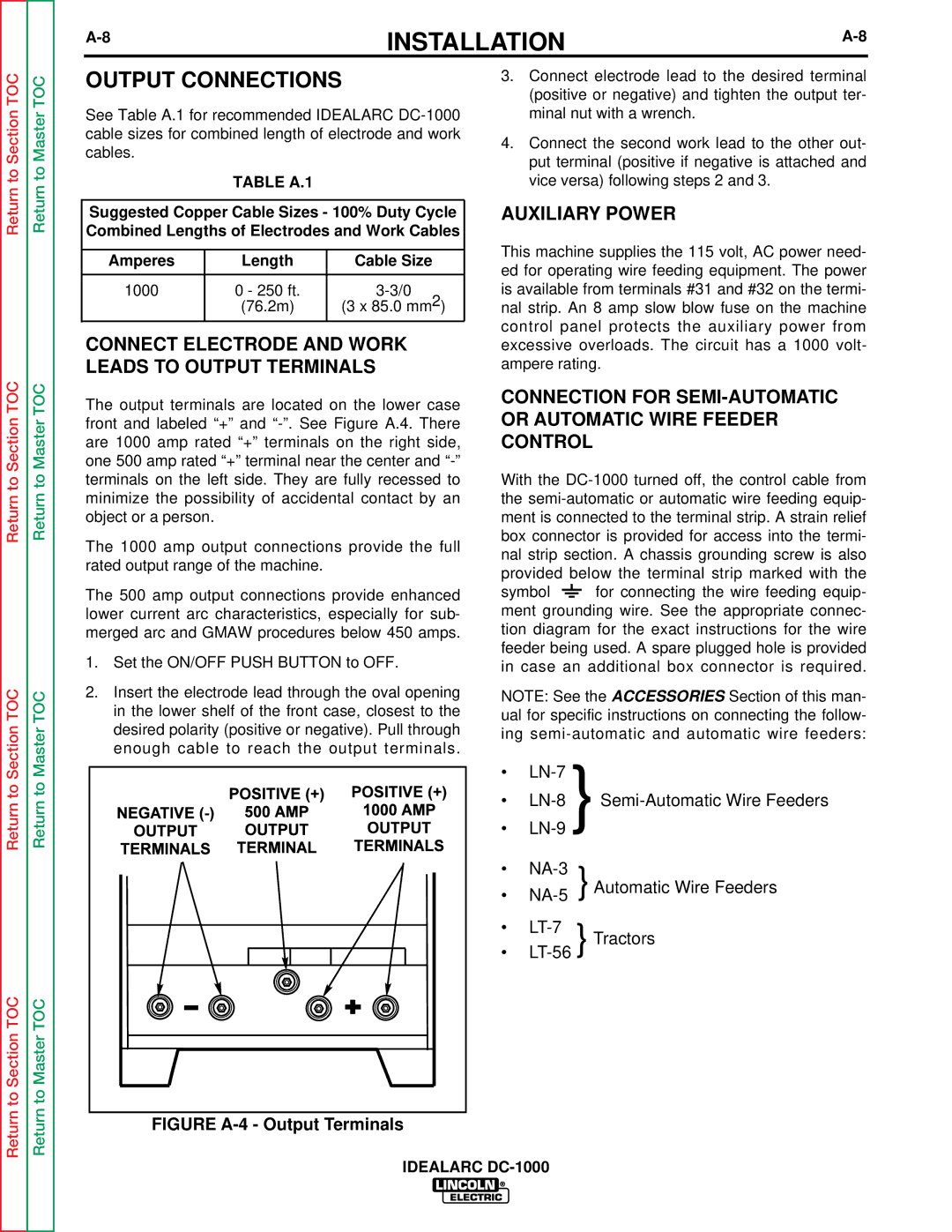

The output terminals are located on the lower case | CONNECTION FOR | ||||||||||||||||

|

|

| |||||||||||||||

|

|

| OR AUTOMATIC WIRE FEEDER | ||||||||||||||

Section | Master | front and labeled “+” and | |||||||||||||||

are 1000 amp rated “+” terminals on the right side, | CONTROL |

| |||||||||||||||

|

|

|

| ||||||||||||||

|

|

| one 500 amp rated “+” terminal near the center and |

|

|

|

|

|

|

|

|

| |||||

to | to | terminals on the left side. They are fully recessed to | With the | ||||||||||||||

minimize the possibility of accidental contact by an | the | ||||||||||||||||

Return | Return | ||||||||||||||||

object or a person. |

|

|

| box connector is provided for access into the termi- | |||||||||||||

|

|

|

|

|

| ment is connected to the terminal strip. A strain relief | |||||||||||

|

|

| The 1000 amp output connections provide the full | nal strip section. A chassis grounding screw is also | |||||||||||||

|

|

| rated output range of the machine. |

|

| ||||||||||||

|

|

|

|

| provided below the terminal strip marked with the | ||||||||||||

|

|

|

|

|

|

|

| ||||||||||

|

|

| The 500 amp output connections provide enhanced | symbol |

|

|

|

|

|

|

| for connecting the wire feeding equip- | |||||

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

| lower current arc characteristics, especially for sub- | ment grounding wire. See the appropriate connec- | |||||||||||||

|

|

| merged arc and GMAW procedures below 450 amps. | tion diagram for the exact instructions for the wire | |||||||||||||

|

|

| 1. Set the ON/OFF PUSH BUTTON to OFF. | feeder being used. A spare plugged hole is provided | |||||||||||||

|

|

| in case an additional box connector is required. | ||||||||||||||

TOC | TOC | 2. Insert the electrode lead through the oval opening | NOTE: See the ACCESSORIES Section of this man- | |||

in the lower shelf of the front case, closest to the | ual for specific instructions on connecting the follow- | |||||

Section | Master | desired polarity (positive or negative). Pull through | ing | |||

enough cable to reach the output terminals. | • | } |

| |||

|

|

|

|

| ||

to | to |

| • | |||

Return | Return |

| ||||

| • |

| ||||

|

|

|

| |||

|

|

| • | } Automatic Wire Feeders | ||

|

|

| • | |||

|

|

| • | } Tractors | ||

|

|

| • | |||

to Section TOC | to Master TOC |

|

|

|

|

|

Return | Return | FIGURE |

|

|

|

|

|

|

|

|

|

| |

|

| IDEALARC |

|

| ||