Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

| TROUBLESHOOTING & REPAIR | ||||||

|

|

| |||||

|

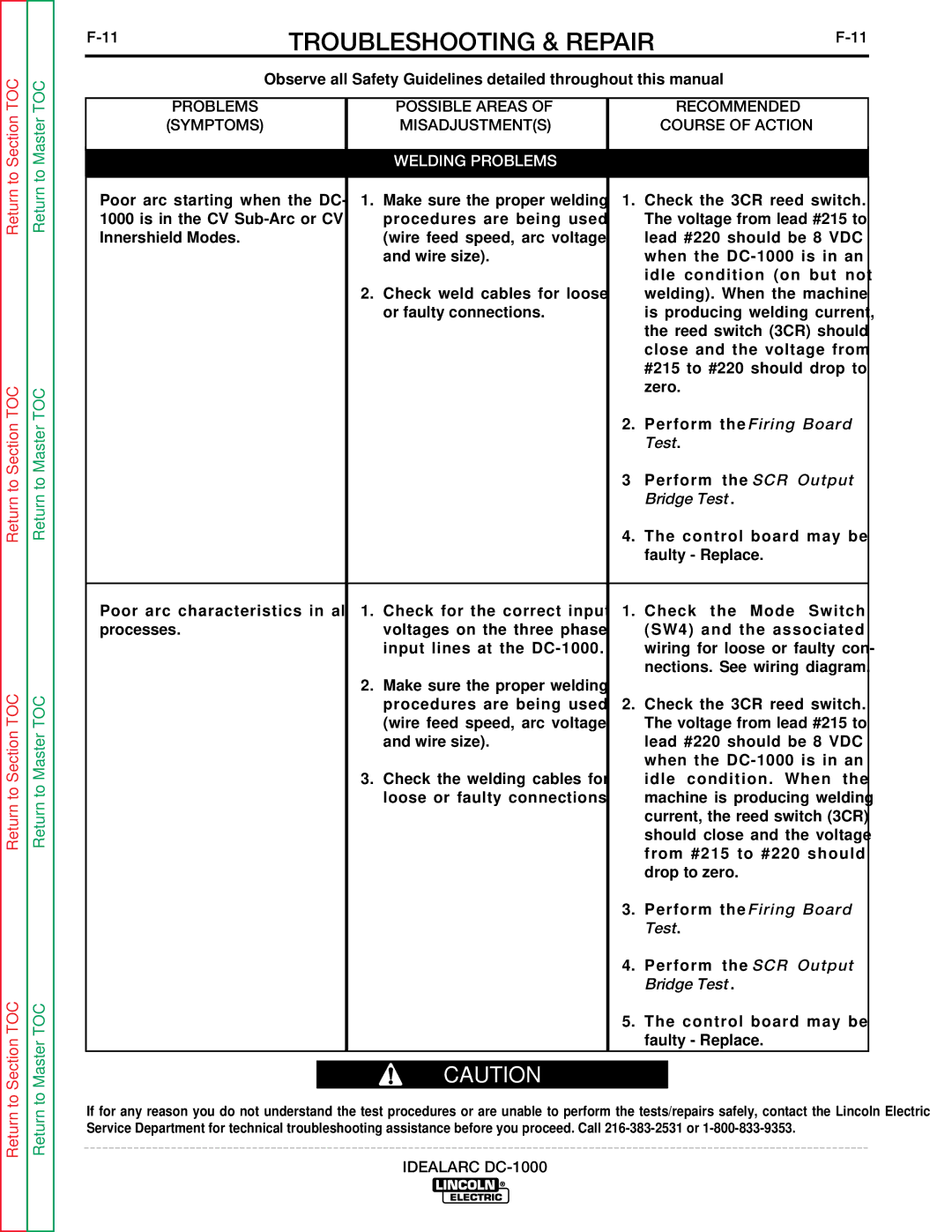

| Observe all Safety Guidelines detailed throughout this manual |

| ||||

|

|

|

|

|

|

| |

| PROBLEMS |

|

| POSSIBLE AREAS OF |

| RECOMMENDED | |

| (SYMPTOMS) |

| MISADJUSTMENT(S) |

| COURSE OF ACTION | ||

|

|

|

|

|

|

|

|

|

|

|

| WELDING PROBLEMS |

|

|

|

|

|

|

|

|

| ||

| Poor arc starting when the DC- | 1. | Make sure the proper welding | 1. | Check the 3CR reed switch. | ||

| 1000 is in the CV |

| procedures are being used |

| The voltage from lead #215 to | ||

| Innershield Modes. |

|

| (wire feed speed, arc voltage |

| lead #220 should be 8 VDC | |

|

|

|

| and wire size). |

| when the | |

|

|

|

|

|

| idle condition (on but not | |

|

|

| 2. | Check weld cables for loose |

| welding). When the machine | |

|

|

|

| or faulty connections. |

| is producing welding current, | |

|

|

|

|

|

| the reed switch (3CR) should | |

|

|

|

|

|

| close and the voltage from | |

|

|

|

|

|

| #215 to #220 should drop to | |

|

|

|

|

|

| zero. |

|

|

|

|

|

| 2. | Perform the Firing Board | |

|

|

|

|

|

| Test. |

|

|

|

|

|

| 3 | Perform the | SCR Output |

|

|

|

|

|

| Bridge Test. |

|

|

|

|

|

| 4. | The control board may be | |

|

|

|

|

|

| faulty - Replace. | |

|

|

|

|

|

|

| |

| Poor arc characteristics in all | 1. | Check for the correct input | 1. | Check the | Mode Switch | |

| processes. |

|

| voltages on the three phase |

| (SW4) and the associated | |

|

|

|

| input lines at the |

| wiring for loose or faulty con- | |

|

|

|

|

|

| nections. See wiring diagram. | |

|

|

| 2. Make sure the proper welding |

|

|

| |

|

|

|

| procedures are being used | 2. | Check the 3CR reed switch. | |

|

|

|

| (wire feed speed, arc voltage |

| The voltage from lead #215 to | |

|

|

|

| and wire size). |

| lead #220 should be 8 VDC | |

|

|

|

|

|

| when the | |

|

|

| 3. | Check the welding cables for |

| idle condition. When the | |

|

|

|

| loose or faulty connections. |

| machine is producing welding | |

|

|

|

|

|

| current, the reed switch (3CR) | |

|

|

|

|

|

| should close and the voltage | |

|

|

|

|

|

| from #215 to #220 should | |

|

|

|

|

|

| drop to zero. |

|

|

|

|

|

| 3. | Perform the Firing Board | |

|

|

|

|

|

| Test. |

|

|

|

|

|

| 4. | Perform the | SCR Output |

|

|

|

|

|

| Bridge Test. |

|

|

|

|

|

| 5. | The control board may be | |

|

|

|

|

|

| faulty - Replace. | |

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call