Marathon Monitors Inc.

TUNING

Before tuning, please read Chapter 2, Operation, to learn how to select and change a parameter.

This chapter has five topics:

∙WHAT IS TUNING?

∙AUTOMATIC TUNING

∙MANUAL TUNING

∙COMMISSIONING OF MOTORISED VALVE CONTROLLERS

∙GAIN SCHEDULING

WHAT IS TUNING?

In tuning, you match the characteristics of the controller to those of the process being controlled in order to obtain good control. Good control means:

∙Stable,

∙No overshoot, or undershoot, of the process variable setpoint

∙Quick response to deviations from the setpoint caused by external disturbances, thereby rapidly restoring the process variable to the setpoint value.

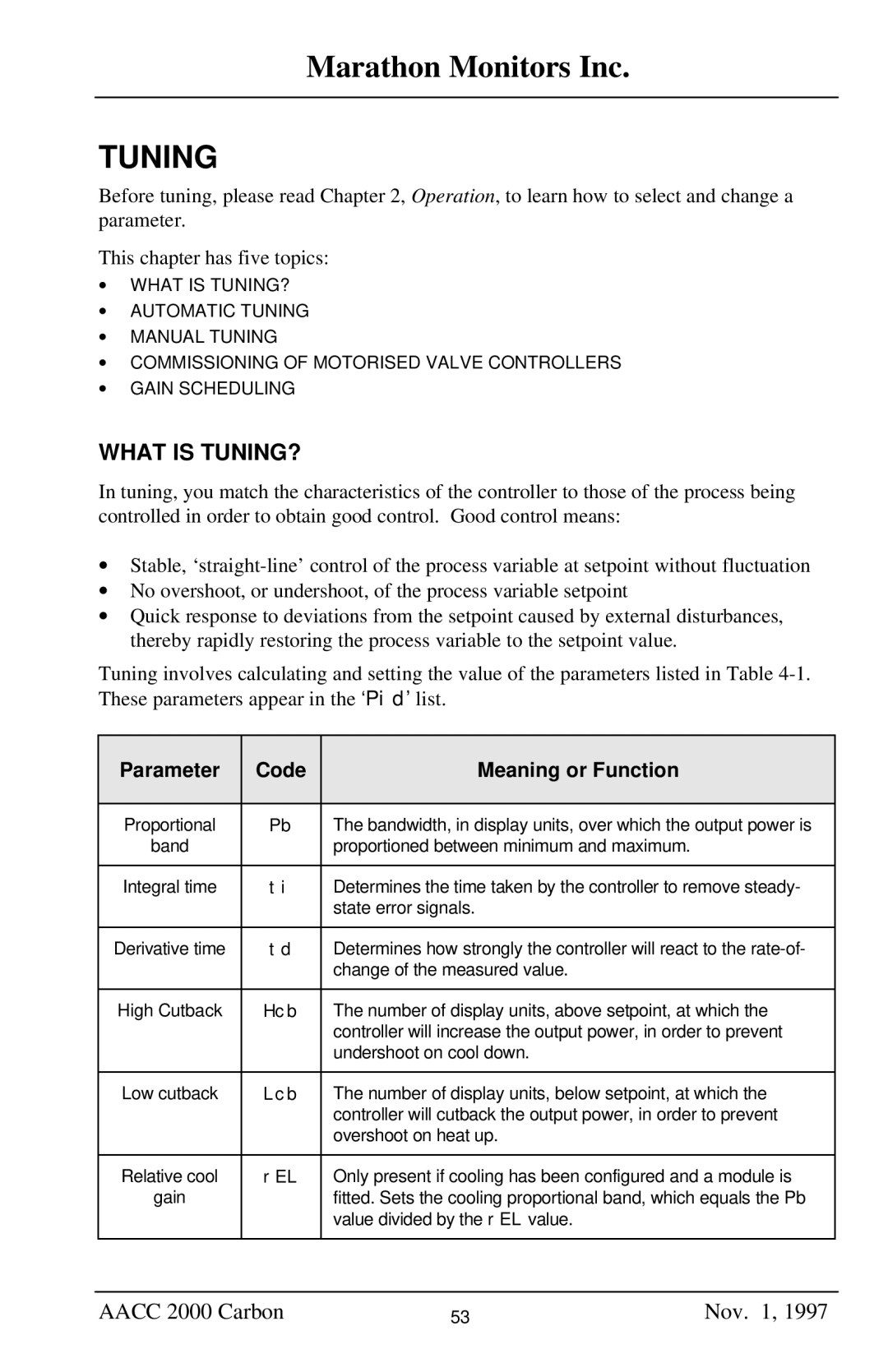

Tuning involves calculating and setting the value of the parameters listed in Table

Parameter | Code | Meaning or Function |

|

|

|

Proportional | Pb | The bandwidth, in display units, over which the output power is |

band |

| proportioned between minimum and maximum. |

|

|

|

Integral time | ti | Determines the time taken by the controller to remove steady- |

|

| state error signals. |

|

|

|

Derivative time | td | Determines how strongly the controller will react to the |

|

| change of the measured value. |

|

|

|

High Cutback | Hcb | The number of display units, above setpoint, at which the |

|

| controller will increase the output power, in order to prevent |

|

| undershoot on cool down. |

|

|

|

Low cutback | Lcb | The number of display units, below setpoint, at which the |

|

| controller will cutback the output power, in order to prevent |

|

| overshoot on heat up. |

|

|

|

Relative cool | rEL | Only present if cooling has been configured and a module is |

gain |

| fitted. Sets the cooling proportional band, which equals the Pb |

|

| value divided by the rEL value. |

|

|

|

AACC 2000 Carbon | 53 | Nov. 1, 1997 |