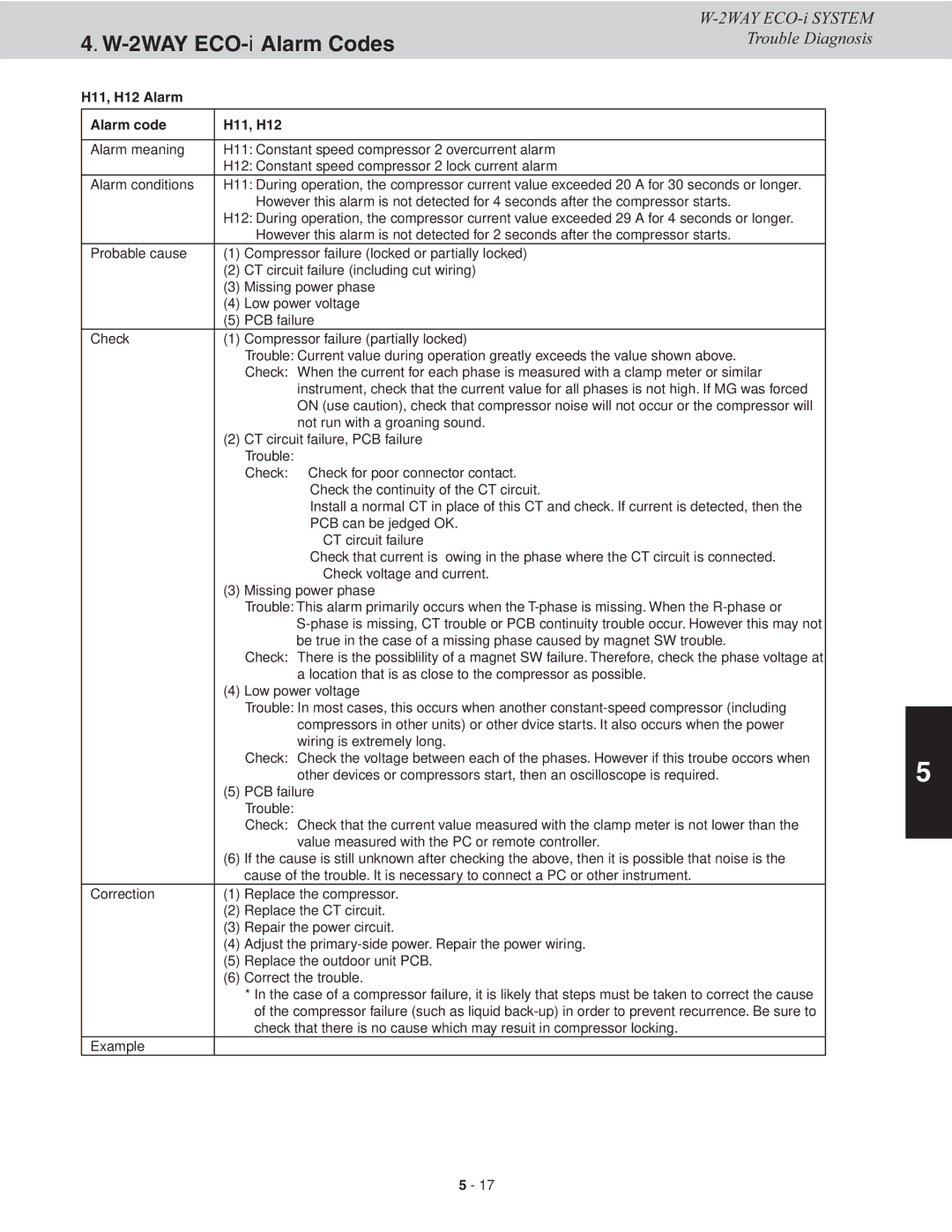

4. W-2WAY ECO-i Alarm Codes

H11, H12 Alarm

Alarm code | H11, H12 | |

|

| |

Alarm meaning | H11: Constant speed compressor 2 overcurrent alarm | |

| H12: Constant speed compressor 2 lock current alarm | |

Alarm conditions | H11: During operation, the compressor current value exceeded 20 A for 30 seconds or longer. | |

|

| However this alarm is not detected for 4 seconds after the compressor starts. |

| H12: During operation, the compressor current value exceeded 29 A for 4 seconds or longer. | |

|

| However this alarm is not detected for 2 seconds after the compressor starts. |

Probable cause | (1) Compressor failure (locked or partially locked) | |

| (2) | CT circuit failure (including cut wiring) |

| (3) | Missing power phase |

| (4) | Low power voltage |

| (5) | PCB failure |

Check | (1) Compressor failure (partially locked) | |

|

| Trouble: Current value during operation greatly exceeds the value shown above. |

|

| Check: When the current for each phase is measured with a clamp meter or similar |

|

| instrument, check that the current value for all phases is not high. If MG was forced |

|

| ON (use caution), check that compressor noise will not occur or the compressor will |

|

| not run with a groaning sound. |

| (2) | CT circuit failure, PCB failure |

|

| Trouble: |

|

| Check: • Check for poor connector contact. |

|

| • Check the continuity of the CT circuit. |

|

| • Install a normal CT in place of this CT and check. If current is detected, then the |

|

| PCB can be jedged OK. |

|

| →CT circuit failure |

|

| • Check that current is flowing in the phase where the CT circuit is connected. |

|

| →Check voltage and current. |

| (3) | Missing power phase |

|

| Trouble: This alarm primarily occurs when the |

|

| |

|

| be true in the case of a missing phase caused by magnet SW trouble. |

|

| Check: There is the possiblility of a magnet SW failure. Therefore, check the phase voltage at |

|

| a location that is as close to the compressor as possible. |

| (4) | Low power voltage |

|

| Trouble: In most cases, this occurs when another |

|

| compressors in other units) or other dvice starts. It also occurs when the power |

|

| wiring is extremely long. |

|

| Check: Check the voltage between each of the phases. However if this troube occors when |

|

| other devices or compressors start, then an oscilloscope is required. |

| (5) | PCB failure |

|

| Trouble: |

|

| Check: Check that the current value measured with the clamp meter is not lower than the |

|

| value measured with the PC or remote controller. |

| (6) | If the cause is still unknown after checking the above, then it is possible that noise is the |

|

| cause of the trouble. It is necessary to connect a PC or other instrument. |

Correction | (1) Replace the compressor. | |

| (2) | Replace the CT circuit. |

| (3) | Repair the power circuit. |

| (4) | Adjust the |

| (5) | Replace the outdoor unit PCB. |

| (6) | Correct the trouble. |

|

| * In the case of a compressor failure, it is likely that steps must be taken to correct the cause |

|

| of the compressor failure (such as liquid |

|

| check that there is no cause which may resuit in compressor locking. |

Example | — |

|

5

5 - 17