5. Recovering Refrigerant

(2) If the remote controller

1Determine the outdoor unit where the unit No. setting (S007) (3P DIP switch) (Blue) on the outdoor unit control PCB is set to No. 1.

2

3Leave the unit running for a while, and touch the gas tubing with fingers to determine whether the unit is running in cooling or heating mode.

If it is in heating, follow the step 4 and later procedures.

Cooling : low temperature (68 °F or lower)

Heating : high temperature (140 °F or higher)

CAUTION

The gas tubing becomes hot (140 °F or higher) in heating mode. Be careful so as not to be burnt when touching the tubing.

4Release the

2 | |

|

5

* Switching of the

6

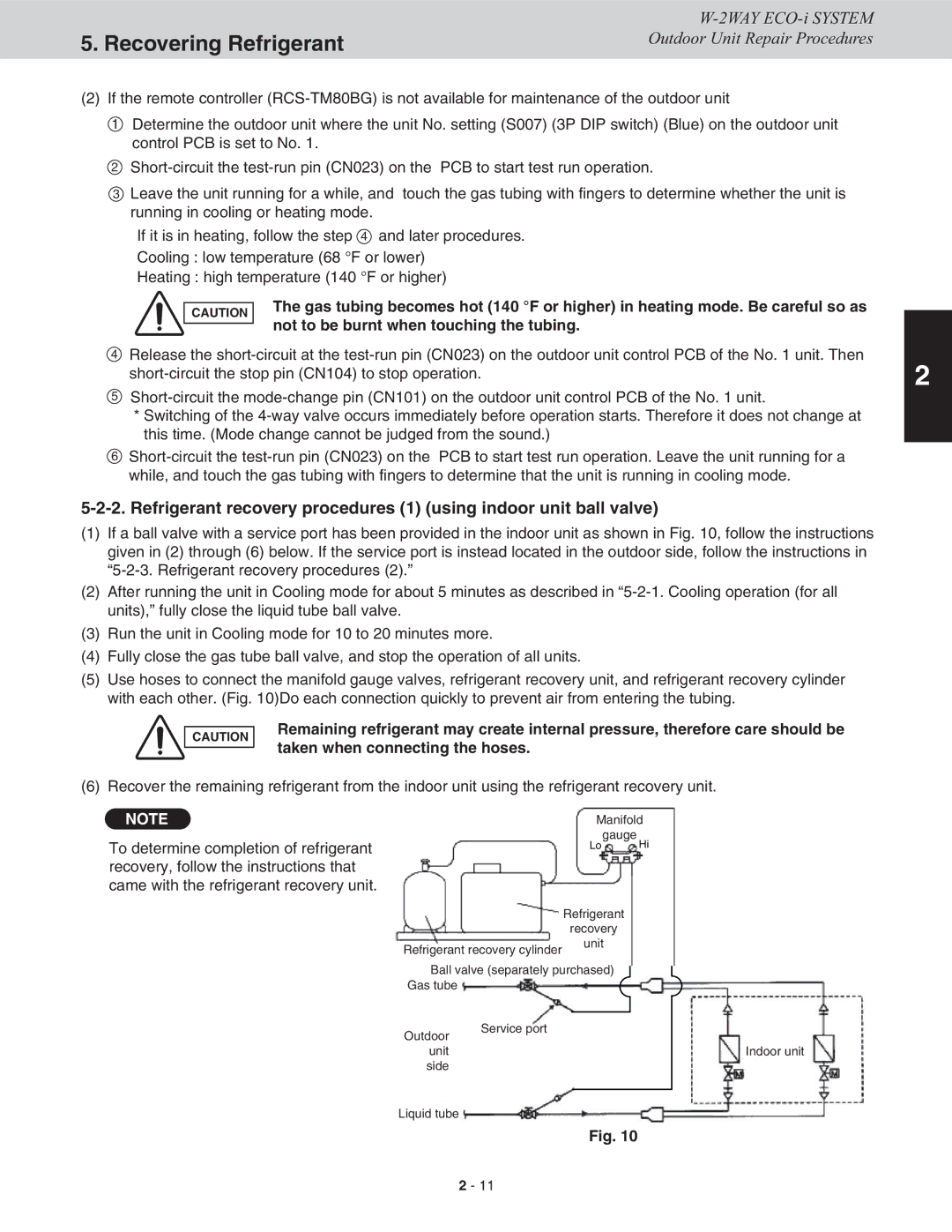

(1)If a ball valve with a service port has been provided in the indoor unit as shown in Fig. 10, follow the instructions given in (2) through (6) below. If the service port is instead located in the outdoor side, follow the instructions in

(2)After running the unit in Cooling mode for about 5 minutes as described in

(3)Run the unit in Cooling mode for 10 to 20 minutes more.

(4)Fully close the gas tube ball valve, and stop the operation of all units.

(5)Use hoses to connect the manifold gauge valves, refrigerant recovery unit, and refrigerant recovery cylinder with each other. (Fig. 10)Do each connection quickly to prevent air from entering the tubing.

CAUTION

Remaining refrigerant may create internal pressure, therefore care should be taken when connecting the hoses.

(6) Recover the remaining refrigerant from the indoor unit using the refrigerant recovery unit.

NOTE

To determine completion of refrigerant recovery, follow the instructions that came with the refrigerant recovery unit.

Manifold

gauge

Lo Hi

|

|

|

|

|

|

|

| Refrigerant |

| |||

|

|

|

|

|

|

|

| recovery | ||||

|

|

|

|

|

|

|

|

|

| unit |

| |

|

| Refrigerant recovery | cylinder |

|

|

| ||||||

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| hased) |

| |||

|

|

| ||||||||||

|

|

| Ball | valv | e (separately purc |

| ||||||

| Ga | s tube |

|

|

|

|

|

|

|

|

| |

| Service port |

|

|

|

|

| ||||||

| Outdoor |

|

|

|

|

| ||||||

|

|

|

|

|

| |||||||

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

| ||||

|

|

| unit |

|

|

|

|

|

|

|

| |

|

|

| side |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Liquid tube |

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| Fig. 10 | ||

Indoor unit

2 - 11