Indoor Units

Outdoor Units

Please Read Before Starting

Check of Density Limit

Contents

Trouble Diagnosis

Control Functions

Introduction

Required settings for Test Run

Outdoor unit No.1

Selecting an Outdoor Unit for Operation

Delayed Start of Outdoor Units

Outdoor Unit Operating Rules

Outdoor Unit Stop Rules

Compressor Selection Rules

Compressor Control

Capacity

Type

Inverter Compressor Capacity Control

Compressor Capacity Control

Forced Compressor Stop

Roadmap Control

Compressor Control

Protection control

Roadmap Control after Trip

System Refrigerant Oil Recovery Control

Way Valve Adjustment Control

System refrigerant oil recovery cycle

Start of System Refrigerant Oil Recovery Control

Defrost Control

Refrigerant Oil Recovery Control between Systems

Defrost Methods

Constraint conditions

Frost detection

Outdoor units where defrost occurs

Reverse Cycle Defrost

OFF

Outdoor unit cycle defrost

System defrost end

Defrost end judgment conditions

Oil Control

Other Controls

Refrigerant Control Valve RCV

Operation of Solenoid Valves

Refrigerant Balance Valve RBV Gas Purge Valve

Bypass Valve BPV

Recovery Valve Orvr

Types of Electronic Thermostatic Expansion Valves

Power Initialization

CHDX07263, CHDX09663

SC Circuit Electronic Control Valve MOV4

Outdoor Fan Control

Demand Control

Demand setting Control Demand meaning

Normal Control

Indoor Unit Control of the Electronic Control Valve

Cooling operation

Heating operation

Special Control

Gas tube valve Electronic thermostatic Expansion valve

Rap Valve Kit Control

Indoor Unit Refrigerant Oil Self Recovery Control

Discharge temperature protection list

Discharge Temperature

Discharge sensor failure list

Compressor No

Current Protection

Pressure Sensor Failure

Automatic Backup Operation

Backup Operation

Manual Backup

S010 Compressor 1 backup

S010 switch

Compressor 2 backup

This setting controls the operation of the drain pump

Service Maintenance Functions

Setting Max. fan mode Effect Amount of capacity reduction

Setting Description

Setting No Compatible static pressure psi

Setting Operation

Set at outdoor units that include CCU functions

Speed

Snowfall Sensor Functions Outdoor Eeprom

Other Functions

Symptoms of insufficient gas

Outdoor unit PCB LED indications in judgment mode

Symptoms of overcharge

Memo

Outdoor Unit Repair Procedures

Removing Panels

Procedures

Removing Electrical Component Box and Duct

Remove the upper duct remove 3 screws Fig

Remove the lower duct remove 2 screws, and a hook

Discharging Oil from Oil Separator

Discharging Compressor Oil

Discharging Oil in Compressor

Checking the Oil

Backup operation by disconnecting the outdoor unit

Automatic Backup

Switch on outdoor unit control PCB Action

If the failed outdoor unit is not the No unit

If the failed unit is the No outdoor unit main unit

INV compressor AC1 compressor Setting for backup operation

Backup operation settings for each compressor

Refrigerant Recovery Procedures from outdoor unit

Recovering Refrigerant

Carry out refrigerant recovery

Following equipment and tools are required

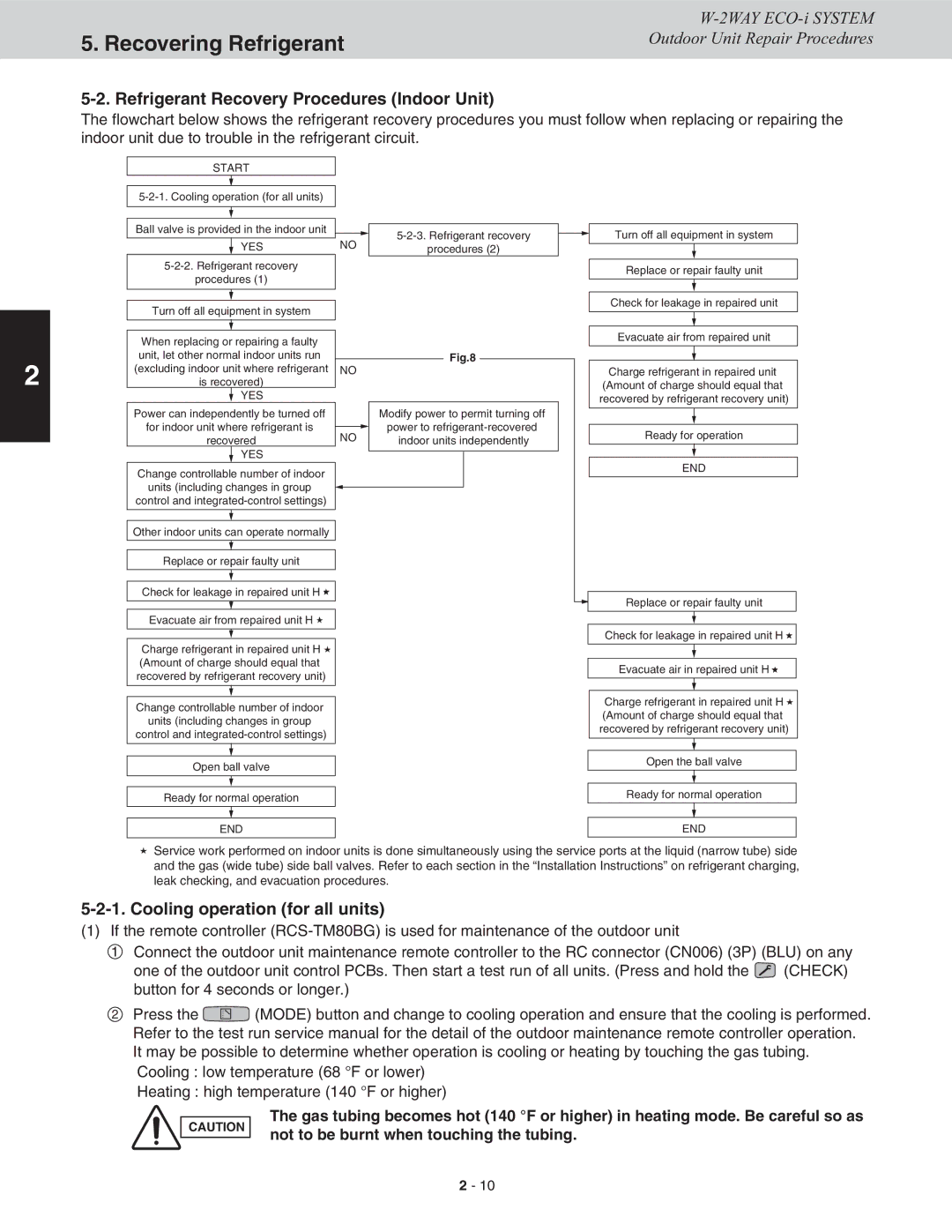

Cooling operation for all units

Refrigerant Recovery Procedures Indoor Unit

Unit

Recovering Refrigerant

Recovery of Refrigerant from Entire System

Pressure Check for Leakage of Outdoor Unit

Checking for Leakage After Repair

Evacuating Repaired Outdoor Unit

Evacuating System

If Refrigerant Has Already Been Charged to Outdoor Unit

Charging Compressor Oil

DPR

If Outdoor Unit Has Not Been Charged with Refrigerant

JT160G-KTTJ

Pumping Out Refrigerant from Outdoor Unit

Pumping Out Refrigerant from Outdoor Unit

Faulty outdoor unit Other outdoor unit

Refrigerant recovery unit

Compressor Trouble Diagnosis and Check Methods

Compressor

Compressor

Replacing all compressors in a failed unit

Replacing all compressors in a system

If a ball valve is installed on the outdoor unit

Dry core cleaning

Cleaning dry core

If a ball valve is not installed on the outdoor unit

Replacing compressors

Removing and Installing Compressors

Removal

Installation

Front view Type

Compressor

Compressor

Replacing multiple compressors Removal

High and Low Pressure Sensors

Installing the High and Low Pressure Sensors

Removing the High and Low Pressure Sensor

Protect the check valves as shown in the figure

Replacing 4-way Valve

Replacing 4-way Valve

Memo

Outdoor Unit Maintenance Remote Controller

Service Checker Section

NN About the outdoor unit maintenance remote controller

System diagram

Overview

NN Outdoor unit alarm history monitor

NN Temperature monitor

NN Mode settings

Functions

NN Functions on the ordinary display

Cooling/heating change Fig

All units start/stop Fig

All units test run Fig

Double-speed

Item code Remarks

NN Display functions

Sample displays

Locations where Œ, , and Ž are displayed as shown in Fig

Meaning of display colon

Display of unit Nos −

Is not displayed

Monitoring Operations

Indoor unit

NN Display of unit No main unit

Operating procedure

Outdoor Unit Alarm History Monitor

Setting mode 1 Operating procedure

Mode Settings

Display of first 4 digits Display of last 4 digits

B are displayed alternately

List of Item Codes

Setting mode 2 Operating procedure

Memo

Remote Controller Functions

Procedure

Simple Settings Function

Remote Controller Functions Section

Item code Setting data Description

List of Simple Setting Items

Detailed Settings Function

Setting data Item code Description

List of Detailed Setting Items

Minutes

No forced operation

DC fan tap operating Purpose Mode

Filter sign on times for each model

Simple setting items

Enabled only in 2WAY Multi heat-pump models

Explanation of operation mode priority change

Function

Cooling or dry Heating Fan Fan not changed

Detailed Settings Function

Setting range Drying

From previous

List of Servicing Functions

Remote Controller Servicing Functions

Test Run Function

Procedure

Operates the unit with the thermostat forced on

Procedure

Outdoor unit sensors

Trouble Diagnosis

Contents of Remote Controller Switch Alarm Display

Possible cause of malfunction Operation

Blinking OFF

Outdoor Unit Control Panel LED Display

Display meaning

Example Unit No Item code sensor address Discharge temp. TD

Check procedure

Sensor Temperature Relationship Table

Alarm code Alarm meaning

2WAY ECO-i Alarm Codes

2WAY ECO-i Alarm Codes

E12 Alarm Alarm code

E06 Alarm Alarm code

E15 Alarm Alarm code

S004 S005

E20 Alarm Alarm code

E16 Alarm Alarm code

E24 Alarm Alarm code

CN001

E26 Alarm Alarm code

E25 Alarm Alarm code

E29 Alarm Alarm code

F04, F05 Alarm Alarm code

F07, F24 Alarm Alarm code

F06, F23 Alarm Alarm code

F12 Alarm Alarm code

F08 Alarm Alarm code

F16 Alarm Alarm code

F31 Alarm Alarm code

F17 Alarm Alarm code

H11, H12 Alarm Alarm code

H15 Alarm Alarm code

H03, H13 Alarm Alarm code

Which may damage the compressor

H06 Alarm Alarm code

H07 Alarm Alarm code

H31 Alarm Alarm code

H08, H27 Alarm Alarm code

L10 Alarm Alarm code

L04 Alarm Alarm code

L17 Alarm Alarm code

L18 Alarm Alarm code

P03, P17 Alarm Alarm code

P05 Alarm Alarm code

P04 Alarm Alarm code

P22 Alarm Alarm code

P16 Alarm Alarm code

Fan circuit on the outdoor unit control PCB

P26 Alarm Alarm code

Blinking inspection display 1 Automatic backup

P29 Alarm Alarm code

Alarm code Blinking inspection display

Alarm meaning Compressor magnet SW seizing detected

Blinking Inspection Display on the Remote Controller

Inspection of Parts

Output Operation

Test Pin

Room temp.sensor

Thermister Characteristics Curve

Indoor heat exch. coil sensor E1, E3

Compressor discharge gas temp. sensor

Memo

Service hvac.service@sna.sanyo.com 201002

![]()

![]()

![]() (Amount of charge should equal that recovered by refrigerant recovery unit)

(Amount of charge should equal that recovered by refrigerant recovery unit)![]()

![]()

![]()

![]() (Amount of charge should equal that recovered by refrigerant recovery unit)

(Amount of charge should equal that recovered by refrigerant recovery unit)![]() (CHECK) button for 4 seconds or longer.)

(CHECK) button for 4 seconds or longer.)![]() (MODE) button and change to cooling operation and ensure that the cooling is performed. Refer to the test run service manual for the detail of the outdoor maintenance remote controller operation. It may be possible to determine whether operation is cooling or heating by touching the gas tubing.

(MODE) button and change to cooling operation and ensure that the cooling is performed. Refer to the test run service manual for the detail of the outdoor maintenance remote controller operation. It may be possible to determine whether operation is cooling or heating by touching the gas tubing.