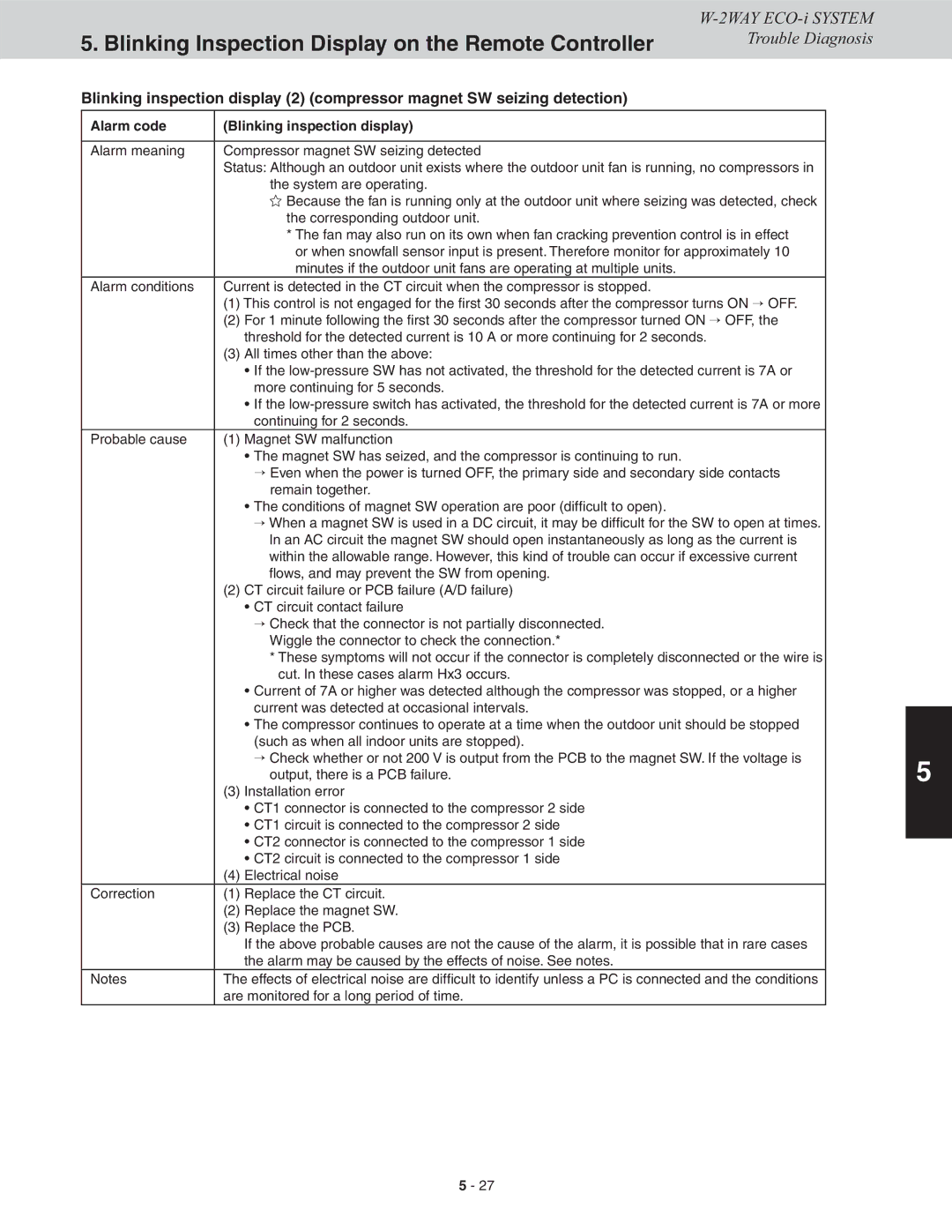

5. Blinking Inspection Display on the Remote Controller

Blinking inspection display (2) (compressor magnet SW seizing detection)

Alarm code | (Blinking inspection display) |

|

|

Alarm meaning | Compressor magnet SW seizing detected |

| Status: Although an outdoor unit exists where the outdoor unit fan is running, no compressors in |

| the system are operating. |

| Because the fan is running only at the outdoor unit where seizing was detected, check |

| the corresponding outdoor unit. |

| * The fan may also run on its own when fan cracking prevention control is in effect |

| or when snowfall sensor input is present. Therefore monitor for approximately 10 |

| minutes if the outdoor unit fans are operating at multiple units. |

Alarm conditions | Current is detected in the CT circuit when the compressor is stopped. |

| (1) This control is not engaged for the first 30 seconds after the compressor turns ON ¡¡OFF. |

| (2) For 1 minute following the first 30 seconds after the compressor turned ON ¡¡OFF, the |

| threshold for the detected current is 10 A or more continuing for 2 seconds. |

| (3) All times other than the above: |

| • If the |

| more continuing for 5 seconds. |

| • If the |

| continuing for 2 seconds. |

Probable cause | (1) Magnet SW malfunction |

| • The magnet SW has seized, and the compressor is continuing to run. |

| ¡ Even when the power is turned OFF, the primary side and secondary side contacts |

| remain together. |

| • The conditions of magnet SW operation are poor (difficult to open). |

| ¡ When a magnet SW is used in a DC circuit, it may be difficult for the SW to open at times. |

| In an AC circuit the magnet SW should open instantaneously as long as the current is |

| within the allowable range. However, this kind of trouble can occur if excessive current |

| flows, and may prevent the SW from opening. |

| (2) CT circuit failure or PCB failure (A/D failure) |

| • CT circuit contact failure |

| ¡ Check that the connector is not partially disconnected. |

| Wiggle the connector to check the connection.* |

| * These symptoms will not occur if the connector is completely disconnected or the wire is |

| cut. In these cases alarm Hx3 occurs. |

| • Current of 7A or higher was detected although the compressor was stopped, or a higher |

| current was detected at occasional intervals. |

| • The compressor continues to operate at a time when the outdoor unit should be stopped |

| (such as when all indoor units are stopped). |

| ¡ Check whether or not 200 V is output from the PCB to the magnet SW. If the voltage is |

| output, there is a PCB failure. |

| (3) Installation error |

| • CT1 connector is connected to the compressor 2 side |

| • CT1 circuit is connected to the compressor 2 side |

| • CT2 connector is connected to the compressor 1 side |

| • CT2 circuit is connected to the compressor 1 side |

| (4) Electrical noise |

Correction | (1) Replace the CT circuit. |

| (2) Replace the magnet SW. |

| (3) Replace the PCB. |

| If the above probable causes are not the cause of the alarm, it is possible that in rare cases |

| the alarm may be caused by the effects of noise. See notes. |

Notes | The effects of electrical noise are difficult to identify unless a PC is connected and the conditions |

| are monitored for a long period of time. |

5

5 - 27