Unit 5: Troubleshooting

INTERFACE TROUBLESHOOTING

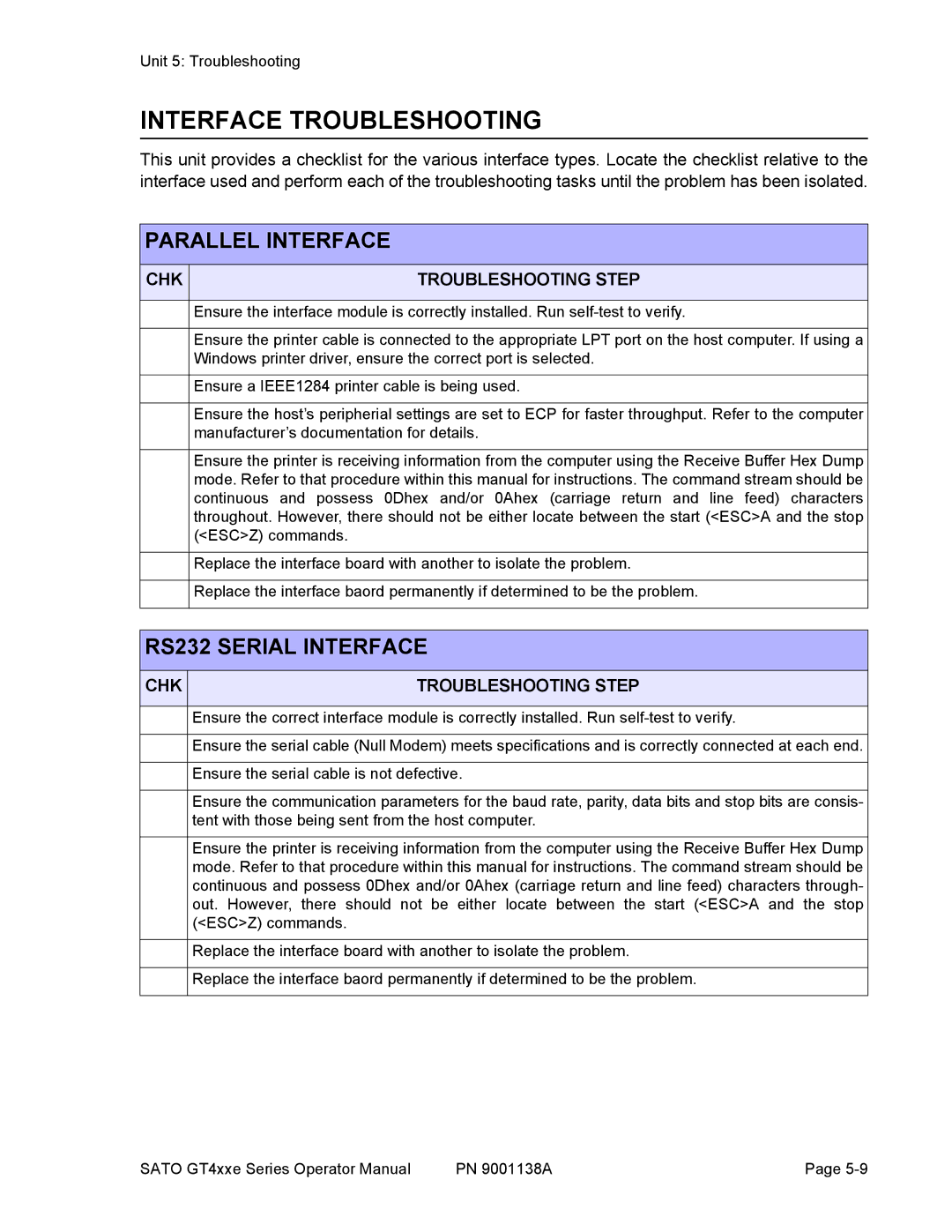

This unit provides a checklist for the various interface types. Locate the checklist relative to the interface used and perform each of the troubleshooting tasks until the problem has been isolated.

PARALLEL INTERFACE

CHK | TROUBLESHOOTING STEP |

|

|

Ensure the interface module is correctly installed. Run

Ensure the printer cable is connected to the appropriate LPT port on the host computer. If using a Windows printer driver, ensure the correct port is selected.

Ensure a IEEE1284 printer cable is being used.

Ensure the host’s peripherial settings are set to ECP for faster throughput. Refer to the computer manufacturer’s documentation for details.

Ensure the printer is receiving information from the computer using the Receive Buffer Hex Dump mode. Refer to that procedure within this manual for instructions. The command stream should be continuous and possess 0Dhex and/or 0Ahex (carriage return and line feed) characters throughout. However, there should not be either locate between the start (<ESC>A and the stop (<ESC>Z) commands.

Replace the interface board with another to isolate the problem.

Replace the interface baord permanently if determined to be the problem.

RS232 SERIAL INTERFACE

CHK | TROUBLESHOOTING STEP |

|

|

Ensure the correct interface module is correctly installed. Run

Ensure the serial cable (Null Modem) meets specifications and is correctly connected at each end.

Ensure the serial cable is not defective.

Ensure the communication parameters for the baud rate, parity, data bits and stop bits are consis- tent with those being sent from the host computer.

Ensure the printer is receiving information from the computer using the Receive Buffer Hex Dump mode. Refer to that procedure within this manual for instructions. The command stream should be continuous and possess 0Dhex and/or 0Ahex (carriage return and line feed) characters through- out. However, there should not be either locate between the start (<ESC>A and the stop (<ESC>Z) commands.

Replace the interface board with another to isolate the problem.

Replace the interface baord permanently if determined to be the problem.

SATO GT4xxe Series Operator Manual | PN 9001138A | Page |