Sitrans

Technical Publications

Safety Guidelines Qualified Personnel

Technical data subject to change

Table of Contents

Maintenance

Appendix C Hart Documentation

Iii

113

Introduction

Applications

Manual

Safety Notes

Safety marking symbols

Short form

Abbreviations and Identifications

Long Form

Description

Specifications

Power

Environmental

Performance

Communications

Outputs

User Interface

Electrodes

Weight

Wetted Parts

Enclosure electronic

Approvals

Process Conditions

Operating Principles

Sitrans LC 500 Transmitter

Operation & Application

Capacitance measurement in a cylindrical metal tank

Non-conductive or conductive contents

Stilling well

Sitrans LC 500 electrode

A non-conductive or irregular tank

Active

Active shield

Measurement Section Probe seal

Inactive

Application Sitrans LC

USL

Level Measurement

Interface Measurement

Switch action

Via the loop current

Fault Signalling

Via Hart

Via the solid-state output

Probe Configuration

Sitrans LC 500 Probe Configuration

Seal Types

Electrode Assembly

Process Connections

Pressure and Temperature Considerations

Non-standard applications

Non-Standard Application Sitrans LC 500 Configuration

Handling Electrodes

Sitrans LC 500 Installation

Installation

Process Cautions

Protection for solid-state switch

Mounting Instructions

Sitrans LC 500 Standard Level Version

Interconnection Sitrans LC

Wiring

Supply

Interconnection

Selecting the correct instrumentation cable

Cable

Multi-drop applications maximum cable length

Is applications maximum cable length

Subtract the capacitance for the device

Which allows for 560 meters on that side

Terminals

Connecting Sitrans LC

Connection Diagram

Grounding instructions

Where the stilling well is welded to the tank 7ML19985GE01

Metal Tanks

Grounding Examples Sitrans LC

System Grounding referencing

Non-Conductive Tanks

Cathodically Protected Metal Tanks

Example

Safety Grounding

Hazardous area Non-hazardous area

Communications

Diagnostics

Typical PLC configuration with Hart

Applications for Solid-state Output

Current values used as signals from digital transmitters

Switch Protection Diode

Factory Settings

Settings

Setting Description

Interconnection

Setting

User Interface

Sitrans LC 500 User Interface

LCD display

Description Menu Group Details

How to access the data

Menu Levels 00 to 0F and 10 to 1F

Access to a menu item

Rotary switch

Adjusting the value

Push-buttons

Transmitter Variable User-defined Functions Units

Transmitter Variables

Quick Start

Start-up Sitrans LC

Start Up

Quick Start Sequence

Num

Rotary Switch Positions Quick Reference

To change from menu 10 to menu

Menu levels 0

To change from menu 00 to menu

Calibration using push-button adjustment

Current percent of span = 14/20 = 70%

Changing stepsize value menu

100% value is set

Start Up

Calibration using Hart

Start Up

Number Description

Number

Maintenance

Maintenance

Test function

Inspections

Maintenance

If you are unable to change settings

Troubleshooting Sitrans LC

Troubleshooting

Error Messages push-button operation

Error Messages and Error Codes

Error Codes Hart

Error Description Cause Message

Appendix a Menu Groups

Stepsize Update Value

Transmitter Variable Settings menu level

Rotary Left Switch Description Values Position Arrow

Menu Items

Lower Sensor Limit

Set the rotary switch to B

Damping

Delta Range Setting

Rotary Switch

Upper Sensor Limit

Description Values Position

Lower Range Value

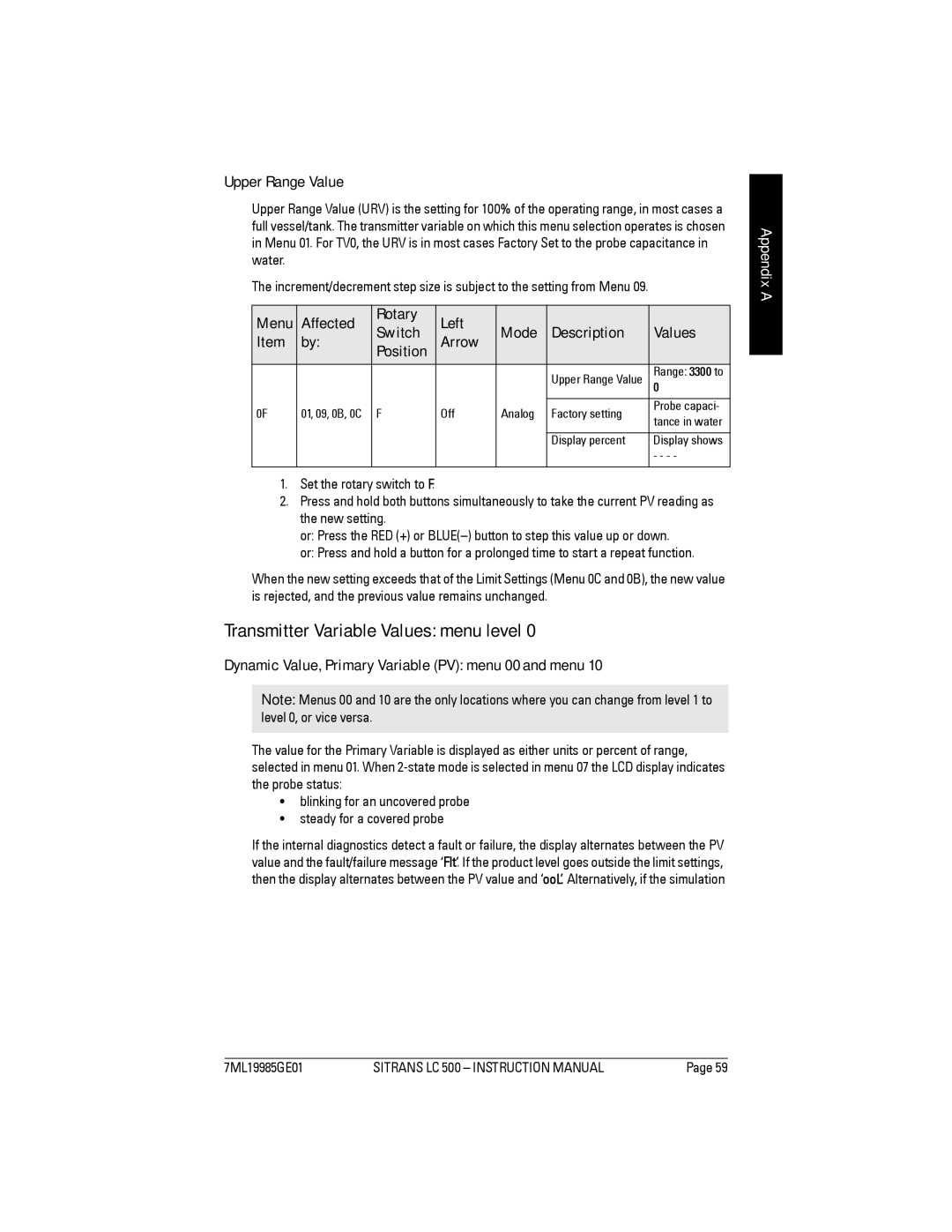

Affected Rotary Left Switch Mode Description

Affected Rotary Left Switch Mode

Dynamic Value, Primary Variable PV menu 00 and menu

Transmitter Variable Values menu level

Upper Range Value

Rotary Switch Left Arrow Description Position

Rotary Left Description Values Switch

To change from menu 10 to menu Set the rotary switch to

Display the Highest / Lowest Recorded Value

Transmitter Variables Dynamic Value menu level

Rotary Left Switch Mode Description Action Values

Upper Threshold Delay 2-state mode

Analog Output Signalling proportional or 2-state menu level

Rotary Left Added Switch Arrow

Indicator

Arrow Indicator

Rotary Left Added Switch

Upper Threshold Setting 2-state mode

Mode Description Values Position

Lower Threshold Setting 2-state mode

Analog Signalling Mode 2-state menu level

State State Low

Rotary Left Mode

State High

State mode must be selected at menu

Analog Fault Signalling 2-state

For detailed information, see Fault Signalling on

22.0 mA

Upper Threshold Delay solid-state output

Digital Output Signalling solid-state output menu level

Rotary Left Des Switch

Identifier Cription

Value

Lower Threshold Delay solid-state output

Upper Threshold Setting solid-state output

Lower Threshold Setting solid-state output

Rotary Left Des Switch Mode

Rotary Left Added Des Switch Mode

Indicator Cription

= cc

Digital Signalling Mode solid-state output

Rotary Left Des Switch Arrow Mode Cription Action

Action Values

Digital Fault Signalling

Rotary Left Switch Mode

Factory Settings

Output Signal Processing Test

Switch Left Arrow Description Display Meaning Position

Miscellaneous

Protection Display Switch Local

Rotary Switch Left Arrow Description Mode Values Position

Settings

Range Inversion

Appendix B

Appendix B LCD display examples

LCD alphanumeric display examples

Hart information

Appendix C Hart Documentation

Hart Device Descriptor DD

Simatic Process Device Manager PDM

Sitrans LC 500 DD Menu/Variable Organization

Hart Response Code Information

Command Description Usage Number

Hart Conformance and Command Class

General Transmitter Information

Command Description Usage

Damping information

Non-volatile Memory Data Storage

Burst mode

Additional Universal Command Specifications

MultiDrop operation

Units conversions

Sitrans LC 500 Block Diagram

Appendix D Block Diagram, and Correlation table, mA to %

Appendix D

Correlation % 100% to 4-20 mA or 20-4 mA

Range 0 100 % Current in mA

Standard Version S-Series, Threaded

Standard Version

Series Threaded

Appendix E

Series Cable Version With weight With anchor

Features Standard Version S-Series, Threaded

Series, Welded Flange

Features Standard Version S-Series, Flanged

Features Standard Version DD-Series

Features Standard Version D-Series

Standard Version D-Series, Machined Flange

Series

SD-Series Probe/Thermal Isolator

Features Standard Version, Probe/ Thermal Isolator

All wetted parts made of PFA

Thermal isolator to prevent

Interface Version, threaded optional sanitary and flanged

Interface Version

Sanitary Version

Features Sanitary Version, Tri-Clamp

Flange Standards

Flanges

Applications Examples

Examples using dimensions above Capacitance in air

Generic Application Calculations

Capacitance in oil

PF = 33.2 pF

Larger tank, dimensions in feet

CAn

Device settings

90.0

08.0

Current loop is in 2-state mode C Hi selected

Application Analog fault signalling 2-state output

State fault signalling enabled F Hi selected

CHi

LSL is set to 7.3 pF

USL is set to 83.50 pF

CE Certificate

Appendix F Approvals

Sitrans LC 500 / Pointek CLS

Appendix F

Hinweis

CE Bescheinigung

Wir erklären hiermit auf eigene Verantwortung, dass der

Instrument label Sitrans LC

Kema certificate and schedules

Appendix F

Appendix F

Appendix F

Appendix F

Appendix F

Appendix F

Appendix F

Namur recommendation NE

Application Specifications

Certificates and Approvals

Approval

Glossary

Glossary

7ML19985GE01

Index

Index

Numerics

Index

Wiring

Quick Reference

Quick Reference Sitrans LC

Rotary Switch Positions Quick Reference

Page

7ml19985GE01