Model 9200 Programmable Dual-loop Controller

Normally “Overshoot” is caused by a buildup of the “Reset” error term, by ignoring this term until the temperature is with PB, the “Reset” term is minimized the thus reduces the overshoot error. You should be cautious not to set the “Change setpoint” value too low. (E.g. if the furnace controls 1700 in a steady state at 50% output and you set the “Change setpoint” value to 40% and the PB value is low, you could find yourself in a situation where you never see 40% output and remain in a PB only control mode.

Default PID Parameters for Loop 1(% Carbon) and Loop 2 (Temperature)

Loop 1 Default PID Parameters | Loop 2 Default PID Parameters |

Proportional Band: 20 | Proportional Band: 4.0 |

Reset: .10 | Reset: 0.10 |

Rate: 0 | Rate: 0 |

Cycle time: 16 | Cycle time: 60 |

The “Cancel” key on some of the screens returns you to the previous screen without any changes be effected. The “Esc” key takes you back to the “Menu” screen.

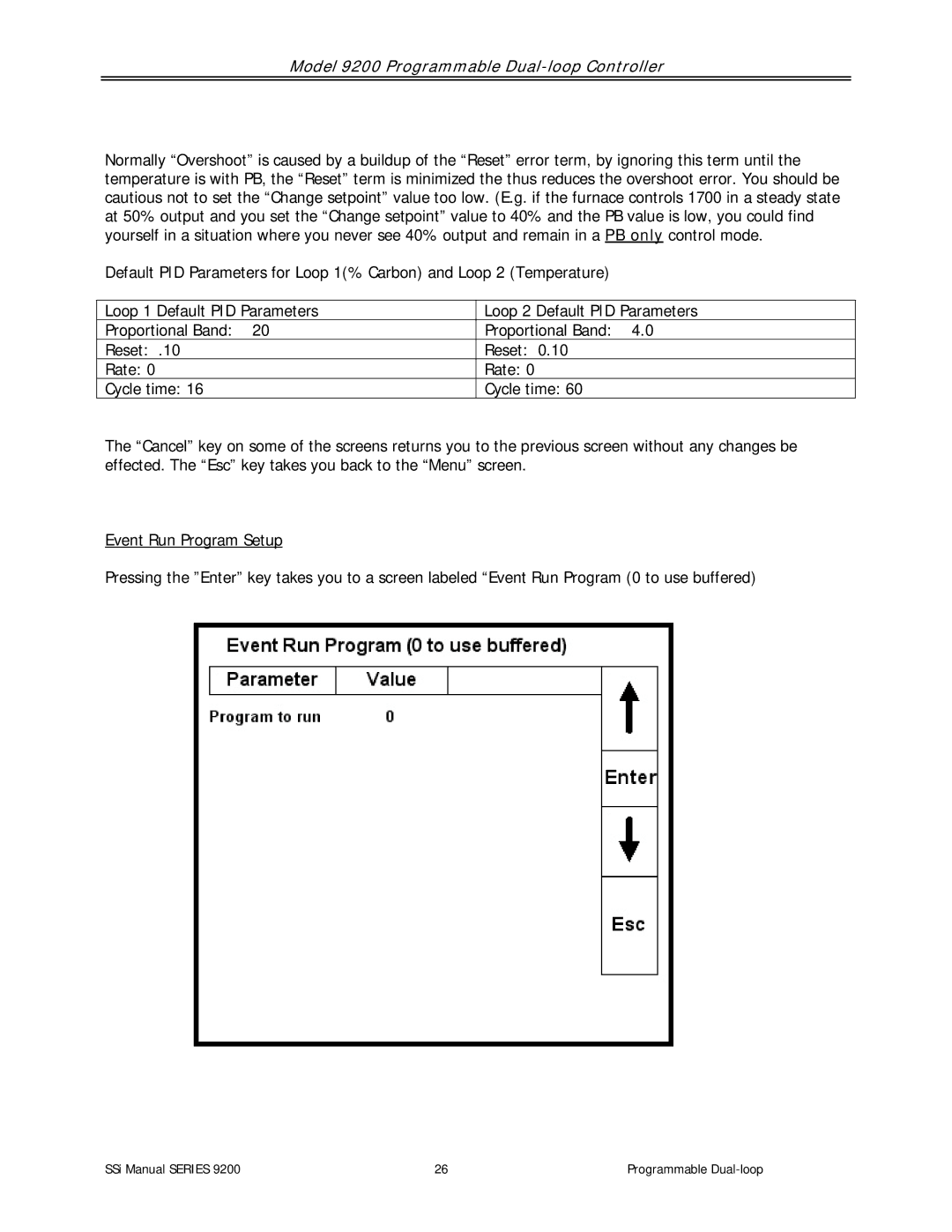

Event Run Program Setup

Pressing the ”Enter” key takes you to a screen labeled “Event Run Program (0 to use buffered)

SSi Manual SERIES 9200 | 26 | Programmable |