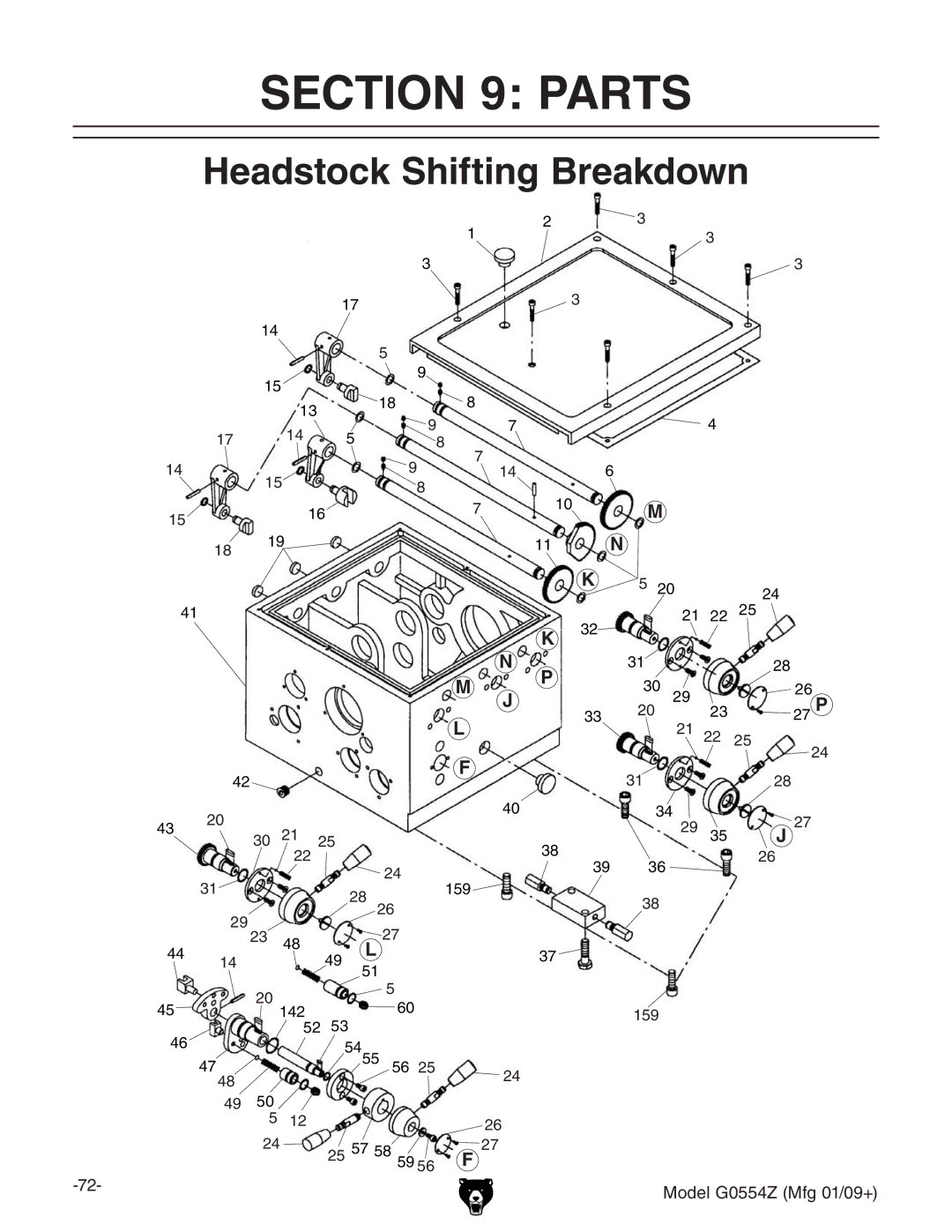

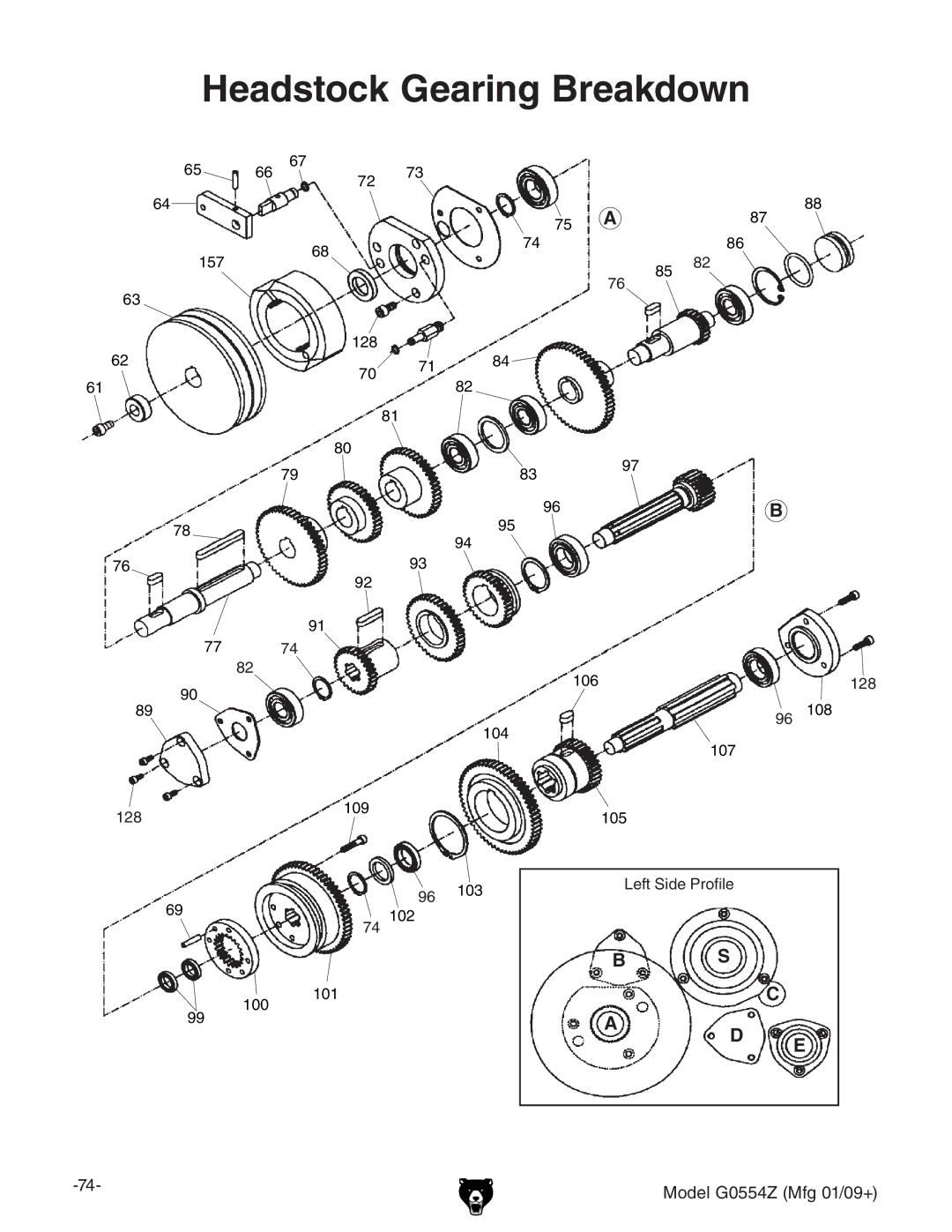

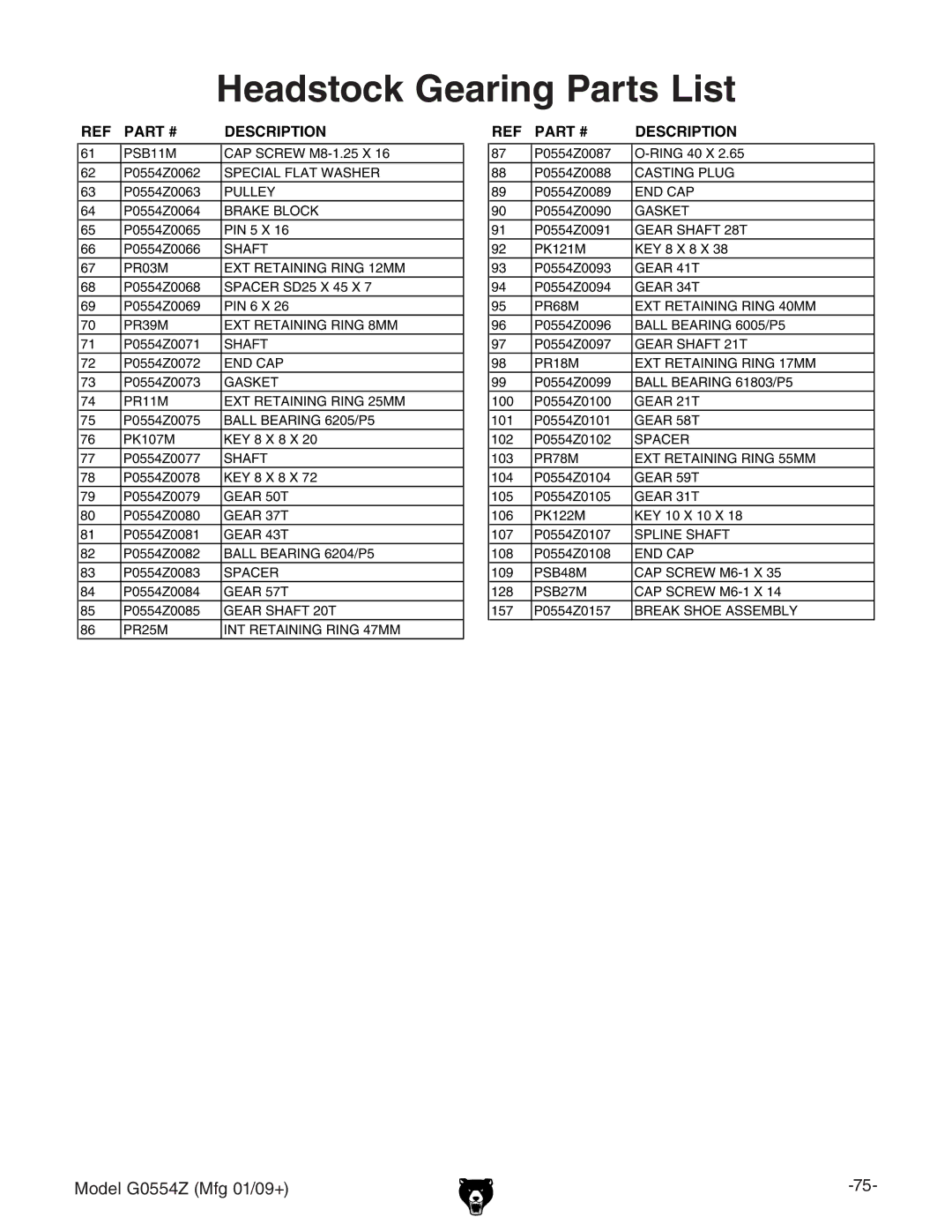

Headstock Gearing Parts List

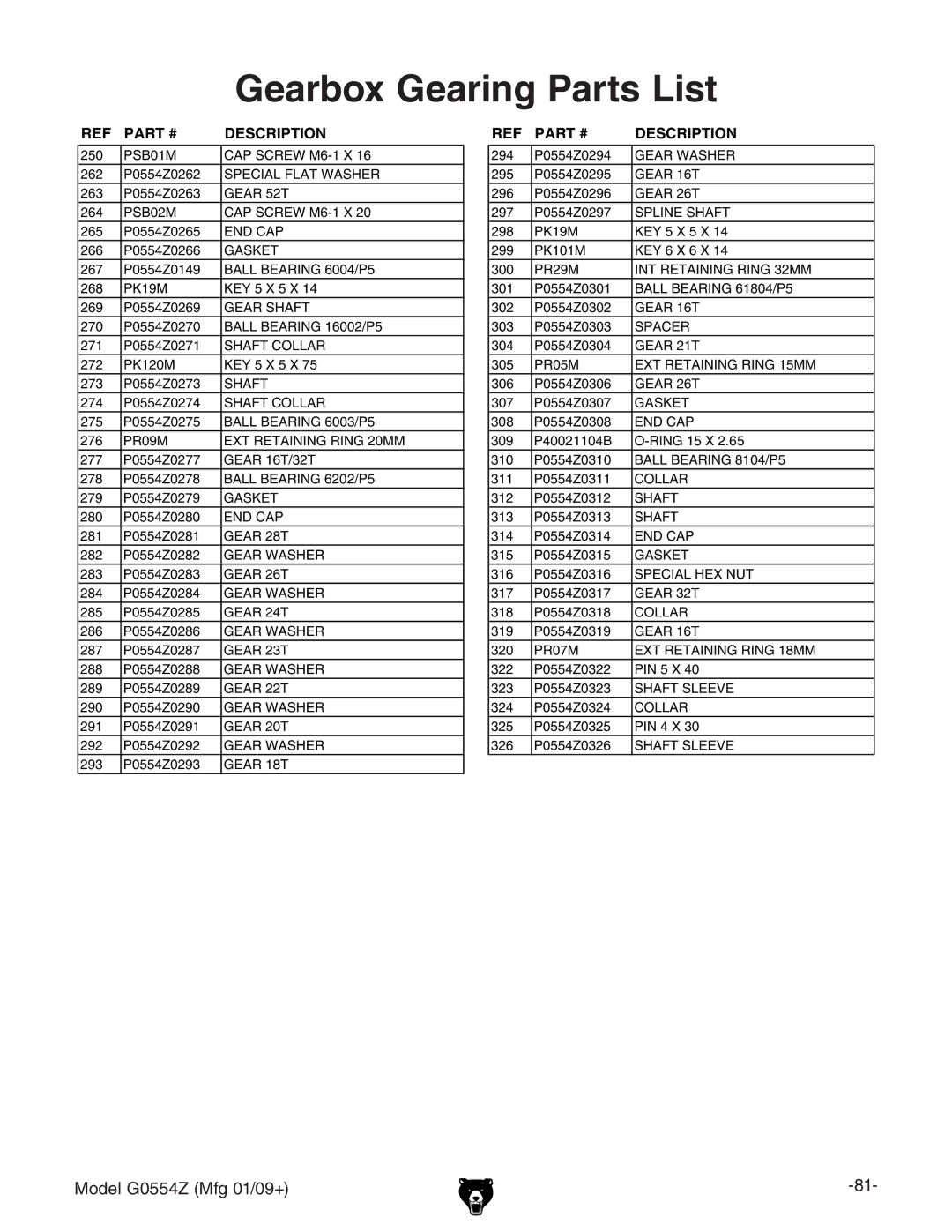

REF | PART # | DESCRIPTION |

|

|

|

61 | PSB11M | CAP SCREW |

62 | P0554Z0062 | SPECIAL FLAT WASHER |

63 | P0554Z0063 | PULLEY |

64 | P0554Z0064 | BRAKE BLOCK |

65 | P0554Z0065 | PIN 5 X 16 |

66 | P0554Z0066 | SHAFT |

67 | PR03M | EXT RETAINING RING 12MM |

68 | P0554Z0068 | SPACER SD25 X 45 X 7 |

69 | P0554Z0069 | PIN 6 X 26 |

70 | PR39M | EXT RETAINING RING 8MM |

71 | P0554Z0071 | SHAFT |

72 | P0554Z0072 | END CAP |

73 | P0554Z0073 | GASKET |

74 | PR11M | EXT RETAINING RING 25MM |

75 | P0554Z0075 | BALL BEARING 6205/P5 |

76 | PK107M | KEY 8 X 8 X 20 |

77 | P0554Z0077 | SHAFT |

78 | P0554Z0078 | KEY 8 X 8 X 72 |

79 | P0554Z0079 | GEAR 50T |

80 | P0554Z0080 | GEAR 37T |

81 | P0554Z0081 | GEAR 43T |

82 | P0554Z0082 | BALL BEARING 6204/P5 |

83 | P0554Z0083 | SPACER |

84 | P0554Z0084 | GEAR 57T |

85 | P0554Z0085 | GEAR SHAFT 20T |

86 | PR25M | INT RETAINING RING 47MM |

REF | PART # | DESCRIPTION |

|

|

|

87 | P0554Z0087 | |

88 | P0554Z0088 | CASTING PLUG |

89 | P0554Z0089 | END CAP |

90 | P0554Z0090 | GASKET |

91 | P0554Z0091 | GEAR SHAFT 28T |

92 | PK121M | KEY 8 X 8 X 38 |

93 | P0554Z0093 | GEAR 41T |

94 | P0554Z0094 | GEAR 34T |

95 | PR68M | EXT RETAINING RING 40MM |

96 | P0554Z0096 | BALL BEARING 6005/P5 |

97 | P0554Z0097 | GEAR SHAFT 21T |

98 | PR18M | EXT RETAINING RING 17MM |

99 | P0554Z0099 | BALL BEARING 61803/P5 |

100 | P0554Z0100 | GEAR 21T |

101 | P0554Z0101 | GEAR 58T |

102 | P0554Z0102 | SPACER |

103 | PR78M | EXT RETAINING RING 55MM |

104 | P0554Z0104 | GEAR 59T |

105 | P0554Z0105 | GEAR 31T |

106 | PK122M | KEY 10 X 10 X 18 |

107 | P0554Z0107 | SPLINE SHAFT |

108 | P0554Z0108 | END CAP |

109 | PSB48M | CAP SCREW |

128 | PSB27M | CAP SCREW |

157 | P0554Z0157 | BREAK SHOE ASSEMBLY |

Model G0554Z (Mfg 01/09+) |