Spindle Bearing

Preload

Your lathe is shipped from the factory with the preload of the spindle tapered roller bearings properly adjusted.

Over time, the bearings will wear and reduce the preload, causing excessive spindle

If the spindle becomes hotter than you can com- fortably leave your hand on after an operation, there may be too much preload and premature wear of the spindle bearings and components could occur.

If your lathe exhibits either of these symptoms, you can adjust the spindle bearing preload.

Tools Needed | Qty |

Hex Wrenches 4, 5 mm | 1 Each |

Spanner Wrench | 1 |

Spindle Lock Key | 1 |

Dial Indicator with Magnetic Base | 1 |

Heavy Dead Blow Hammer | 1 |

Wooden Block | 1 |

Sealant for Headstock Cover | As Needed |

To adjust the spindle bearing preload:

1.Run the lathe for approximately 20 minutes at a medium speed to bring the spindle compo- nents to their normal working temperature.

2.DISCONNECT LATHE FROM POWER!

3.Remove the headstock cover to enable the use of the spanner wrench in later steps.

Note: Do not allow any debris to fall into the headstock when removing the cover.

Tip: Tightly cover the headstock with clean plastic, such as plastic food wrap, to prevent foreign objects dropping into the headstock during this procedure.

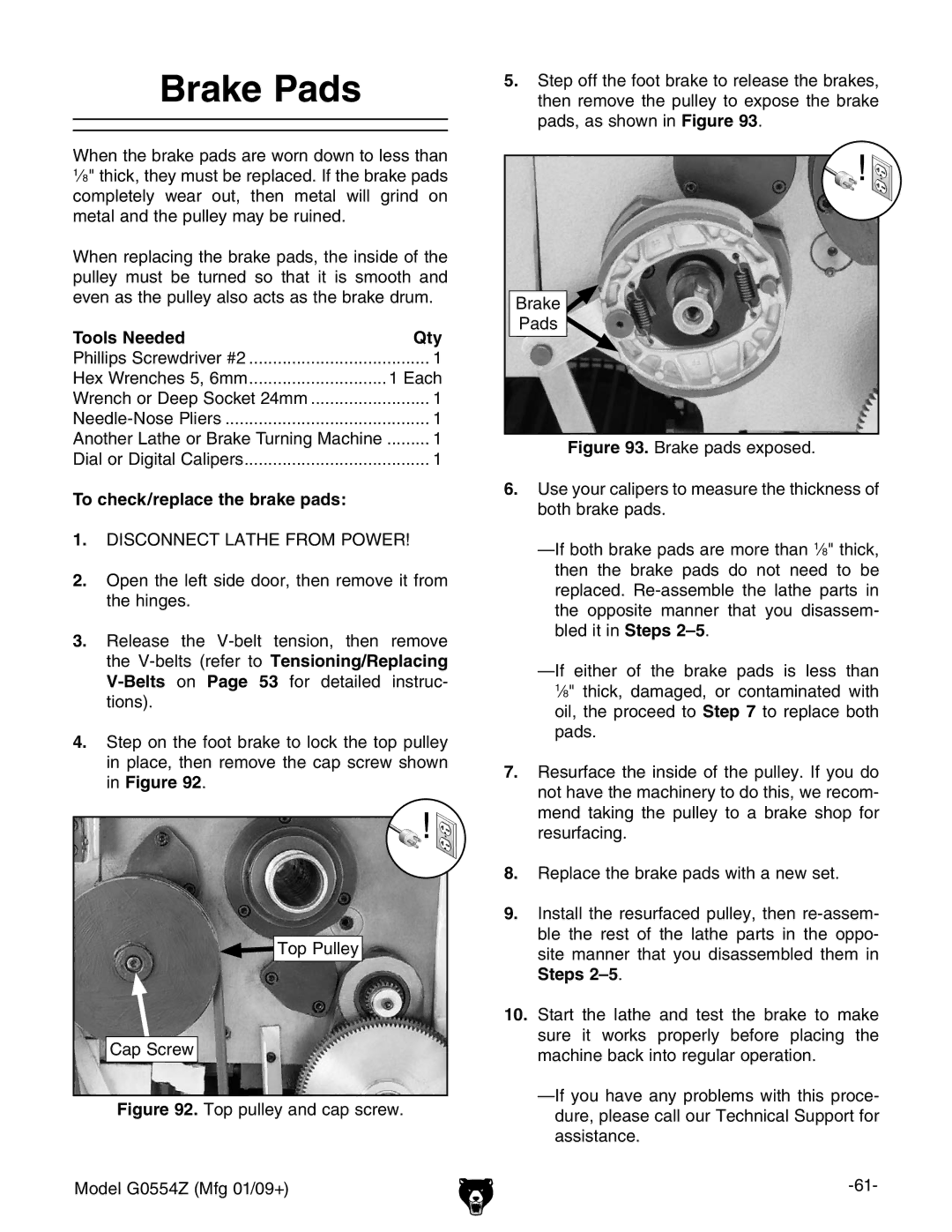

4.Remove the chuck or faceplate from the spin- dle, then open the left side door to expose the outboard end of the spindle and its end cap, as shown in Figure 94.

Spindle |

End Cap |

Figure 94. Spindle outboard end cap exposed.

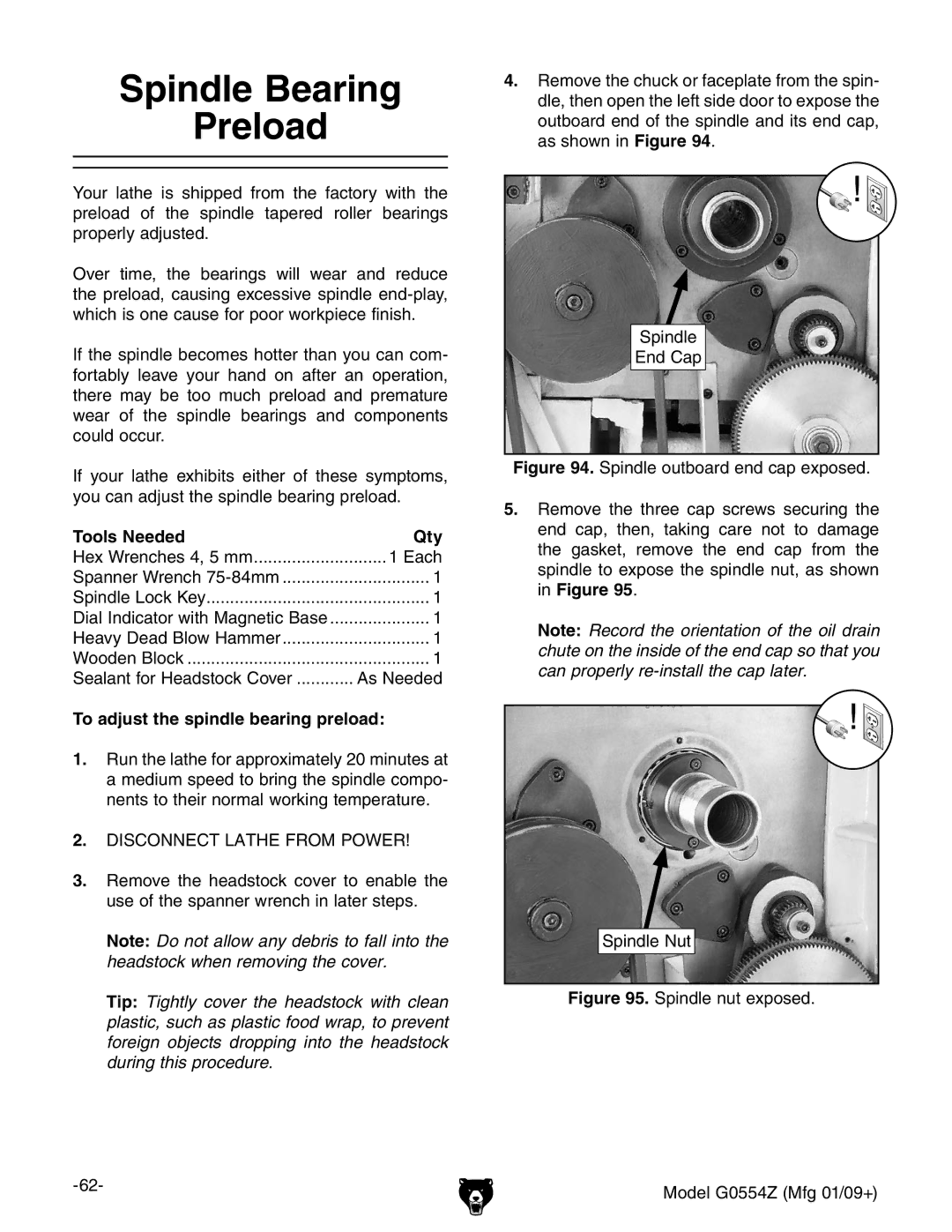

5.Remove the three cap screws securing the end cap, then, taking care not to damage the gasket, remove the end cap from the spindle to expose the spindle nut, as shown in Figure 95.

Note: Record the orientation of the oil drain chute on the inside of the end cap so that you can properly

Spindle Nut |

Figure 95. Spindle nut exposed.

Model G0554Z (Mfg 01/09+) | |

|