Operation and Work Results

Symptom | Possible Cause | Possible Solution | ||

Bad surface | 1. | Incorrect spindle speed or feed rate. | 1. | Adjust for proper spindle speed and feed rate. |

finish. | 2. | Dull tool or poor tool selection. | 2. | Use sharp tools; use correct tool for the operation. |

| 3. | Depth of cut too great. | 3. | Reduce depth of cut and take more passes. |

| 4. | Too much play in gibs. | 4. | Adjust gibs (Page 58). |

| 5. | Tool too high. | 5. | Lower tool position. |

|

|

|

|

|

Entire machine | 1. | Workpiece is unbalanced. | 1. | Reinstall workpiece so it is as centered with the |

vibrates |

|

|

| spindle bore as possible. |

excessively upon | 2. | Worn or broken gear present. | 2. | Inspect gears and replace if necessary. |

startup and while | 3. | Chuck or faceplate has become unbalanced. | 3. | |

running. |

|

|

| local machine shop for help. |

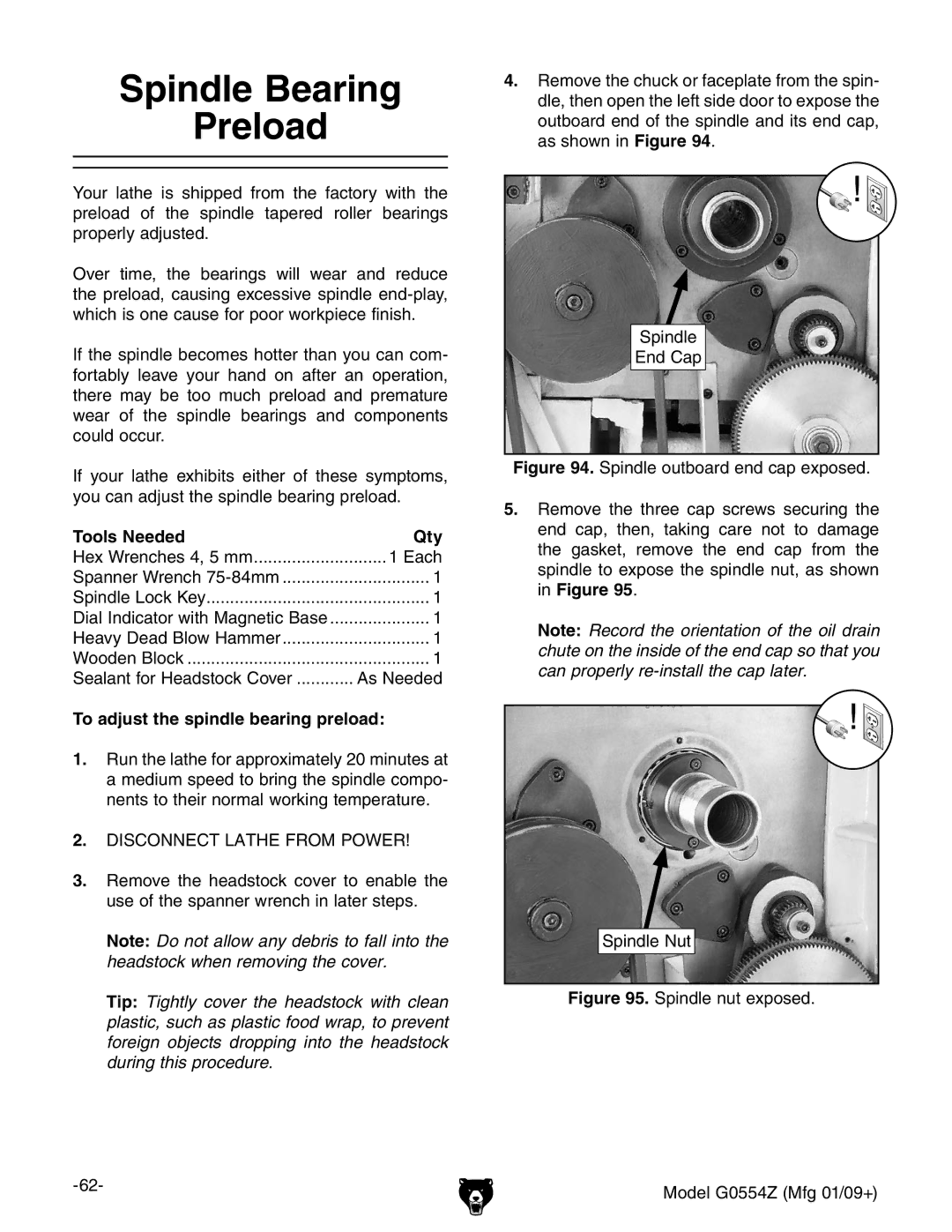

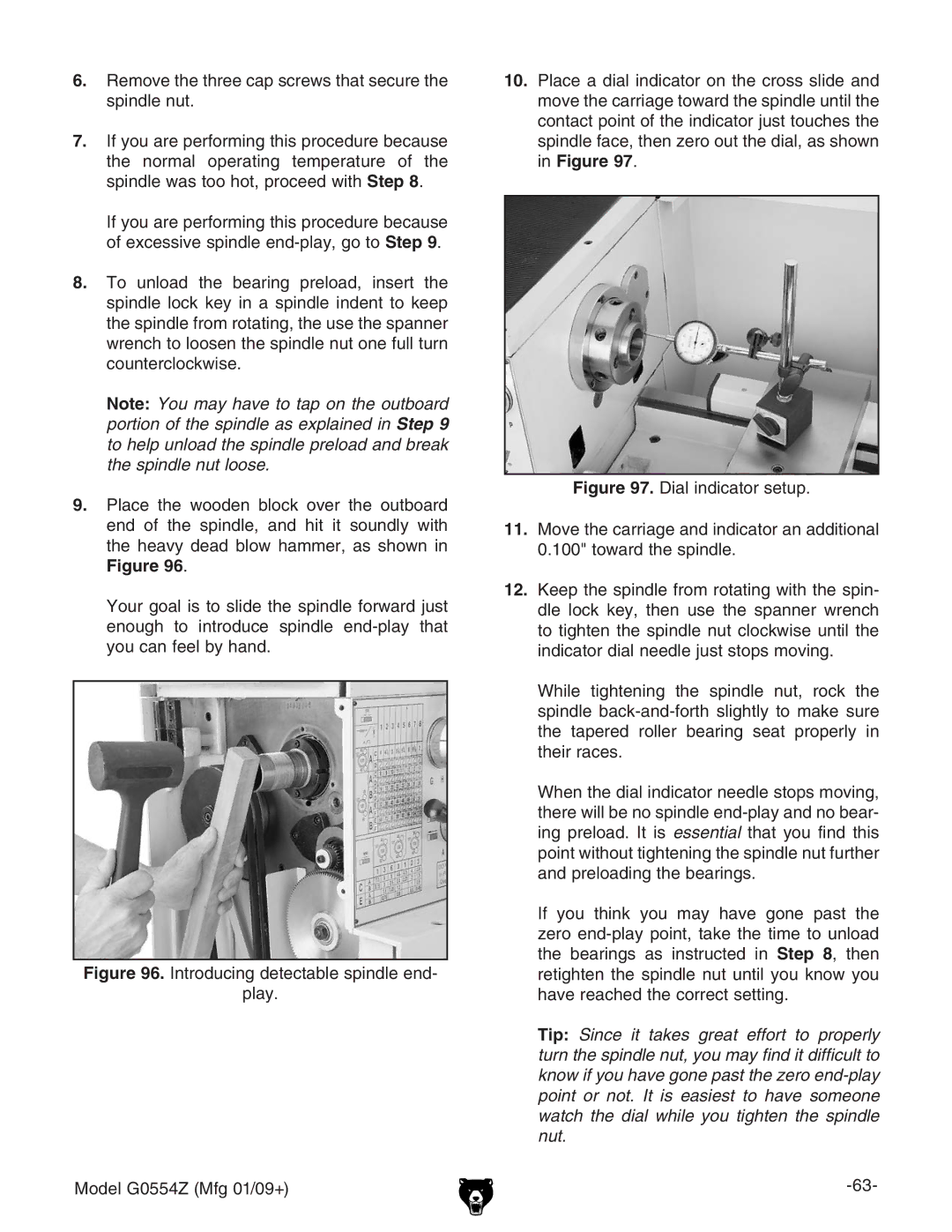

| 4. | Spindle bearings at fault. | 4. | Tighten or replace spindle bearings (Page 62). |

|

|

|

|

|

Cutting tool | 1. | Tool holder not tight enough. | 1. | Check for debris, clean, and retighten. |

or machine | 2. | Cutting tool sticks too far out of tool holder; | 2. | Reinstall cutting tool so no more than 1⁄3 of the total |

components |

| lack of support. |

| length is sticking out of tool holder and it is secured |

vibrate |

|

|

| by at least two post bolts. |

excessively | 3. | Depth of cut too great. | 3. | Reduce depth of cut and take more passes. |

during cutting. | 4. | Gibs are out of adjustment. | 4. | Adjust gibs of affected component (Page 58). |

| 5. | Dull cutting tool. | 5. | Replace or |

| 6. | Incorrect spindle speed or feed rate. | 6. | Use the recommended spindle speed or feed rate. |

|

|

|

|

|

Can't remove | 1. | Quill not retracted all the way back into the | 1. | Turn the quill handwheel until it forces taper out of |

tapered tool from |

| tailstock. |

| quill. |

tailstock quill. | 2. | Debris not removed from taper before inserting | 2. | Always make sure that taper surfaces are clean. |

|

| into quill. |

|

|

|

|

|

|

|

Cross slide, | 1. | Gibs are out of adjustment. | 1. | Adjust gibs of affected component (Page 58). |

compound rest, | 2. | Handwheel is loose. | 2. | Tighten handwheel fasteners. |

or carriage | 3. | Lead screw mechanism worn or out of | 3. | Tighten any loose fasteners on lead screw |

feed has sloppy |

| adjustment. |

| mechanism; adjust backlash (cross slide only, Page |

operation. |

|

|

| 58). |

|

|

|

|

|

Cross slide, | 1. | Gibs are loaded up with shavings or grime. | 1. | Remove gibs, clean ways/dovetails, lubricate, and |

compound rest, |

|

|

| |

or carriage feed | 2. | Gibs are too tight. | 2. | Loosen gibs slightly, and lubricate bedways (Page |

handwheel is |

|

|

| 58). |

hard to move. | 3. | Backlash setting too tight (cross slide only). | 3. | Slightly loosen backlash setting (Page 58). |

| 4. | Bedways are dry. | 4. | Lubricate bedways and carriage components (Page |

|

|

|

| 51). |

|

|

|

|

|

Inaccurate | 1. | Headstock and tailstock are not properly | 1. | Realign the tailstock to the headstock spindle bore |

turning results |

| aligned with each other. |

| center line (Page 33). |

from one end of | 2. | Bedways are not level from | 2. | |

the workpiece to |

|

|

| |

the other. |

|

|

|

|

|

|

|

|

|

Chuck jaws won't | 1. | Chips lodged in the jaws. | 1. | Remove jaws, clean and lubricate chuck threads, |

move or don't |

|

|

| and replace jaws. |

move easily. |

|

|

|

|

|

|

|

|

|

Carriage won't | 1. | Carriage lock lever tightened. | 1. | Loosen the carriage lock lever. |

feed, or hard to | 2. | Gears are not all engaged or broken. | 2. | Adjust gear positions or replace. |

move. | 3. | Gibs are too tight. | 3. | Loosen gibs slightly (Page 58). |

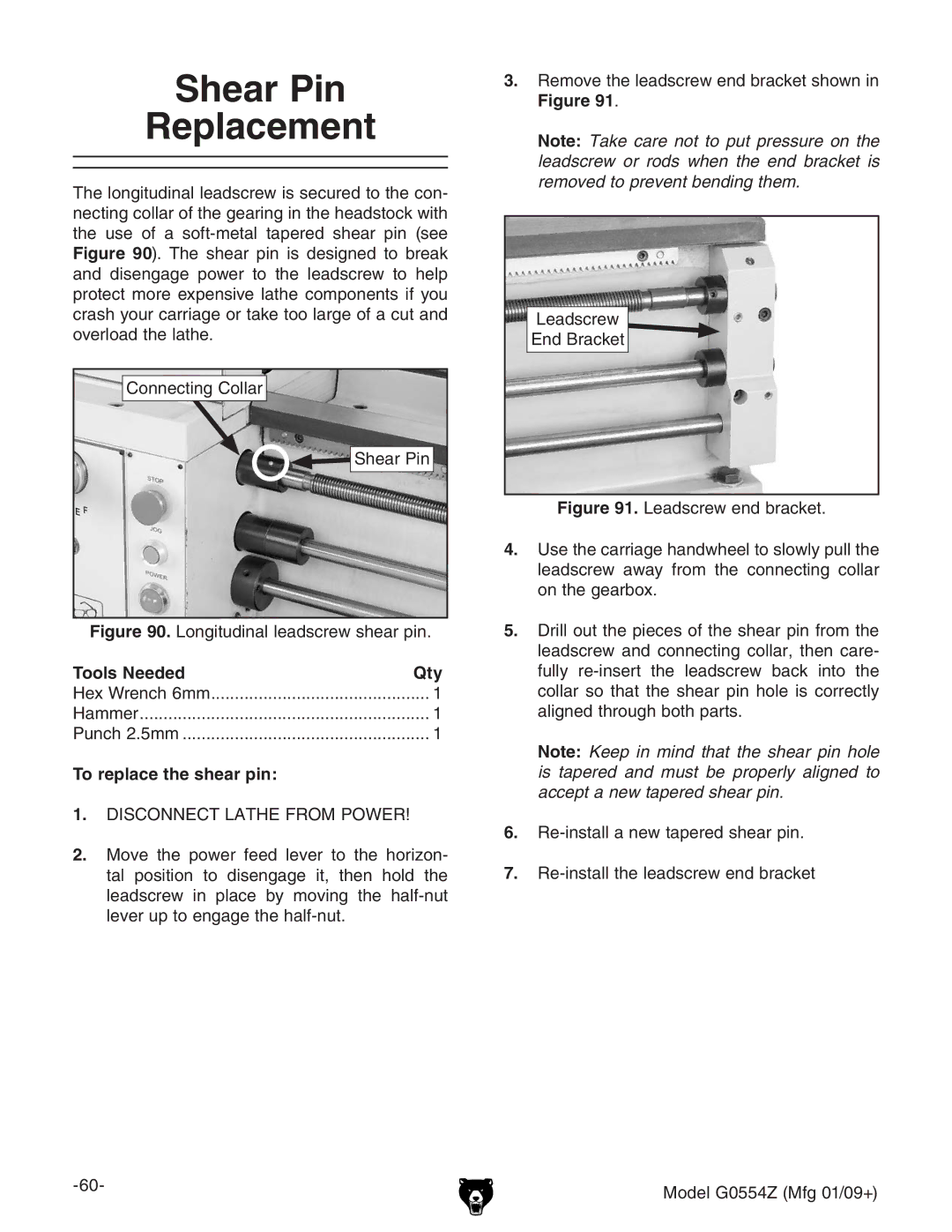

| 4. | Lead screw shear pin has sheared. | 4. | Correct the cause of shear pin breakage, and |

|

|

|

| replace shear pin (Page 60). |

|

|

|

|

|

Tailstock quill will | 1. | Quill lock lever is tightened. | 1. | Loosen quill lock lever. |

not feed out of |

|

|

|

|

tailstock. |

|

|

|

|

|

|

|

|

|

Model G0554Z (Mfg 01/09+) |