2

2.4.5

2.5Safety of the instal- lation

Functioning of the appliance | gis | ||

|

| ||

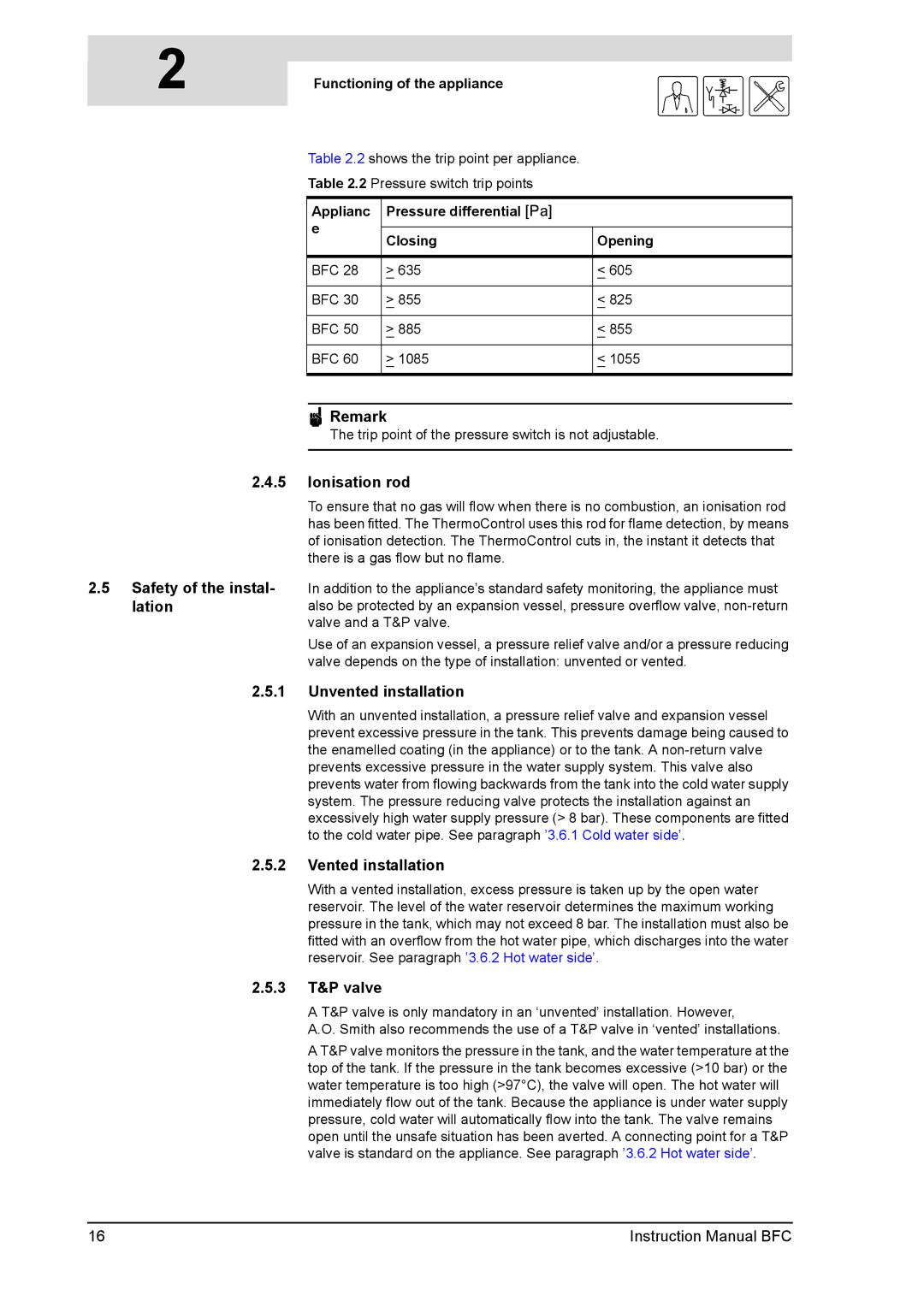

Table 2.2 shows the trip point per appliance. |

| ||

Table 2.2 Pressure switch trip points |

| ||

|

|

| |

Applianc | Pressure differential [Pa] |

| |

e |

|

| |

Closing | Opening | ||

| |||

|

|

| |

BFC 28 | > 635 | < 605 | |

|

|

| |

BFC 30 | > 855 | < 825 | |

|

|

| |

BFC 50 | > 885 | < 855 | |

|

|

| |

BFC 60 | > 1085 | < 1055 | |

|

|

| |

nRemark

The trip point of the pressure switch is not adjustable.

Ionisation rod

To ensure that no gas will flow when there is no combustion, an ionisation rod has been fitted. The ThermoControl uses this rod for flame detection, by means of ionisation detection. The ThermoControl cuts in, the instant it detects that there is a gas flow but no flame.

In addition to the appliance’s standard safety monitoring, the appliance must also be protected by an expansion vessel, pressure overflow valve,

Use of an expansion vessel, a pressure relief valve and/or a pressure reducing valve depends on the type of installation: unvented or vented.

2.5.1Unvented installation

With an unvented installation, a pressure relief valve and expansion vessel prevent excessive pressure in the tank. This prevents damage being caused to the enamelled coating (in the appliance) or to the tank. A

2.5.2Vented installation

With a vented installation, excess pressure is taken up by the open water reservoir. The level of the water reservoir determines the maximum working pressure in the tank, which may not exceed 8 bar. The installation must also be fitted with an overflow from the hot water pipe, which discharges into the water reservoir. See paragraph ’3.6.2 Hot water side’.

2.5.3T&P valve

A T&P valve is only mandatory in an ‘unvented’ installation. However,

A.O. Smith also recommends the use of a T&P valve in ‘vented’ installations.

A T&P valve monitors the pressure in the tank, and the water temperature at the top of the tank. If the pressure in the tank becomes excessive (>10 bar) or the water temperature is too high (>97°C), the valve will open. The hot water will immediately flow out of the tank. Because the appliance is under water supply pressure, cold water will automatically flow into the tank. The valve remains open until the unsafe situation has been averted. A connecting point for a T&P valve is standard on the appliance. See paragraph ’3.6.2 Hot water side’.

16 | Instruction Manual BFC |