12

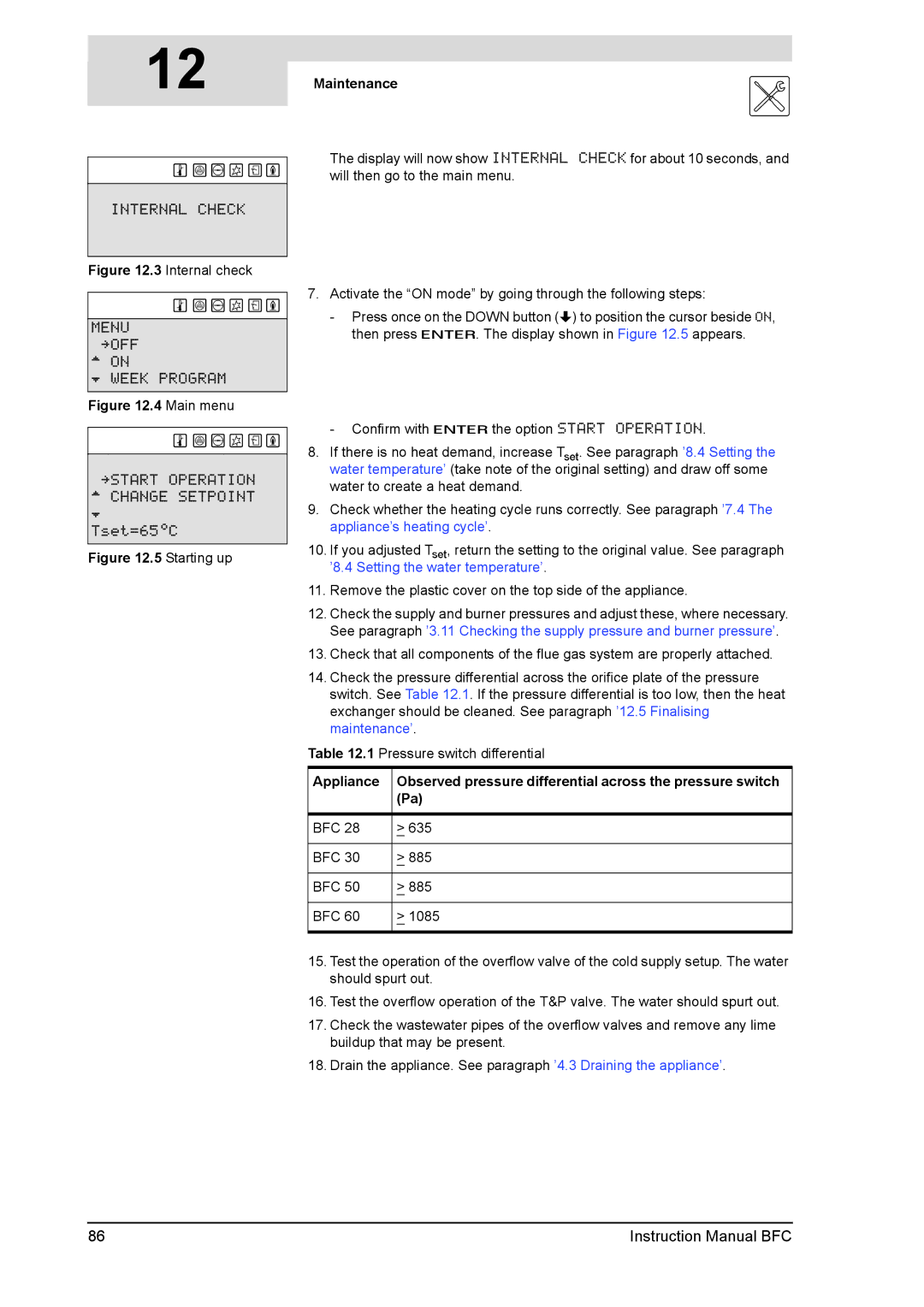

INTERNAL CHECK

Figure 12.3 Internal check

MENU »OFF ^ ON

È WEEK PROGRAM

Figure 12.4 Main menu

»START OPERATION

^CHANGE SETPOINT

È

Tset=65ÉC

Figure 12.5 Starting up

Maintenance | s |

|

The display will now show INTERNAL CHECK for about 10 seconds, and will then go to the main menu.

7.Activate the “ON mode” by going through the following steps:

-Press once on the DOWN button (L) to position the cursor beside ON, then press E. The display shown in Figure 12.5 appears.

-Confirm with Ethe option START OPERATION.

8.If there is no heat demand, increase Tset. See paragraph ’8.4 Setting the water temperature’ (take note of the original setting) and draw off some water to create a heat demand.

9.Check whether the heating cycle runs correctly. See paragraph ’7.4 The appliance’s heating cycle’.

10.If you adjusted Tset, return the setting to the original value. See paragraph ’8.4 Setting the water temperature’.

11.Remove the plastic cover on the top side of the appliance.

12.Check the supply and burner pressures and adjust these, where necessary. See paragraph ’3.11 Checking the supply pressure and burner pressure’.

13.Check that all components of the flue gas system are properly attached.

14.Check the pressure differential across the orifice plate of the pressure switch. See Table 12.1. If the pressure differential is too low, then the heat exchanger should be cleaned. See paragraph ’12.5 Finalising maintenance’.

Table 12.1 Pressure switch differential

Appliance | Observed pressure differential across the pressure switch |

| (Pa) |

|

|

BFC 28 | > 635 |

|

|

BFC 30 | > 885 |

|

|

BFC 50 | > 885 |

|

|

BFC 60 | > 1085 |

|

|

15.Test the operation of the overflow valve of the cold supply setup. The water should spurt out.

16.Test the overflow operation of the T&P valve. The water should spurt out.

17.Check the wastewater pipes of the overflow valves and remove any lime buildup that may be present.

18.Drain the appliance. See paragraph ’4.3 Draining the appliance’.

86 | Instruction Manual BFC |