Chapter 4

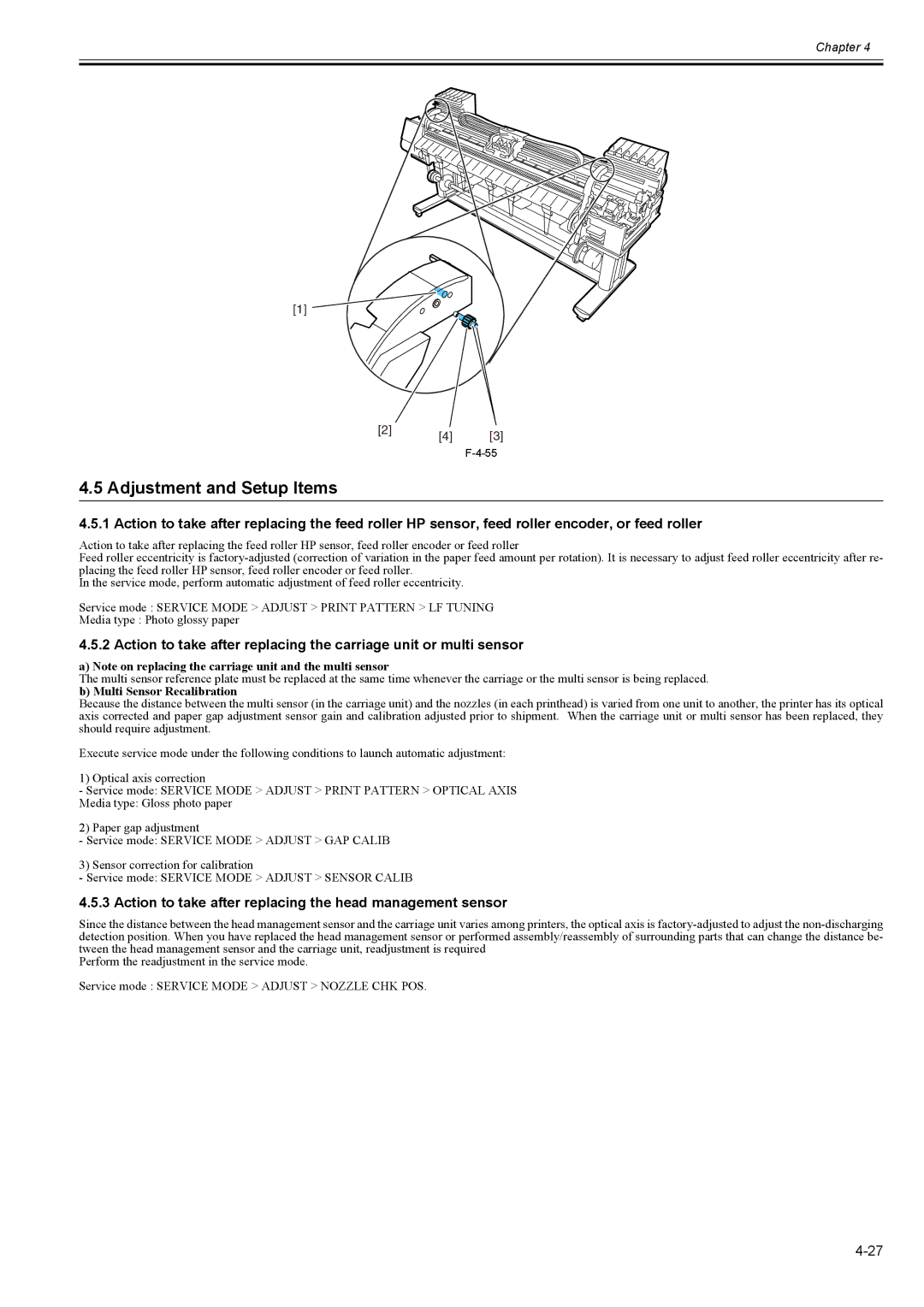

[1] ![]()

[2] [4] [3]

4.5 Adjustment and Setup Items

4.5.1 Action to take after replacing the feed roller HP sensor, feed roller encoder, or feed roller

Action to take after replacing the feed roller HP sensor, feed roller encoder or feed roller

Feed roller eccentricity is

In the service mode, perform automatic adjustment of feed roller eccentricity.

Service mode : SERVICE MODE > ADJUST > PRINT PATTERN > LF TUNING

Media type : Photo glossy paper

4.5.2 Action to take after replacing the carriage unit or multi sensor

a) Note on replacing the carriage unit and the multi sensor

The multi sensor reference plate must be replaced at the same time whenever the carriage or the multi sensor is being replaced. b) Multi Sensor Recalibration

Because the distance between the multi sensor (in the carriage unit) and the nozzles (in each printhead) is varied from one unit to another, the printer has its optical axis corrected and paper gap adjustment sensor gain and calibration adjusted prior to shipment. When the carriage unit or multi sensor has been replaced, they should require adjustment.

Execute service mode under the following conditions to launch automatic adjustment:

1) Optical axis correction

-Service mode: SERVICE MODE > ADJUST > PRINT PATTERN > OPTICAL AXIS Media type: Gloss photo paper

2) Paper gap adjustment

- Service mode: SERVICE MODE > ADJUST > GAP CALIB

3) Sensor correction for calibration

- Service mode: SERVICE MODE > ADJUST > SENSOR CALIB

4.5.3 Action to take after replacing the head management sensor

Since the distance between the head management sensor and the carriage unit varies among printers, the optical axis is

Perform the readjustment in the service mode.

Service mode : SERVICE MODE > ADJUST > NOZZLE CHK POS.