Chapter 2

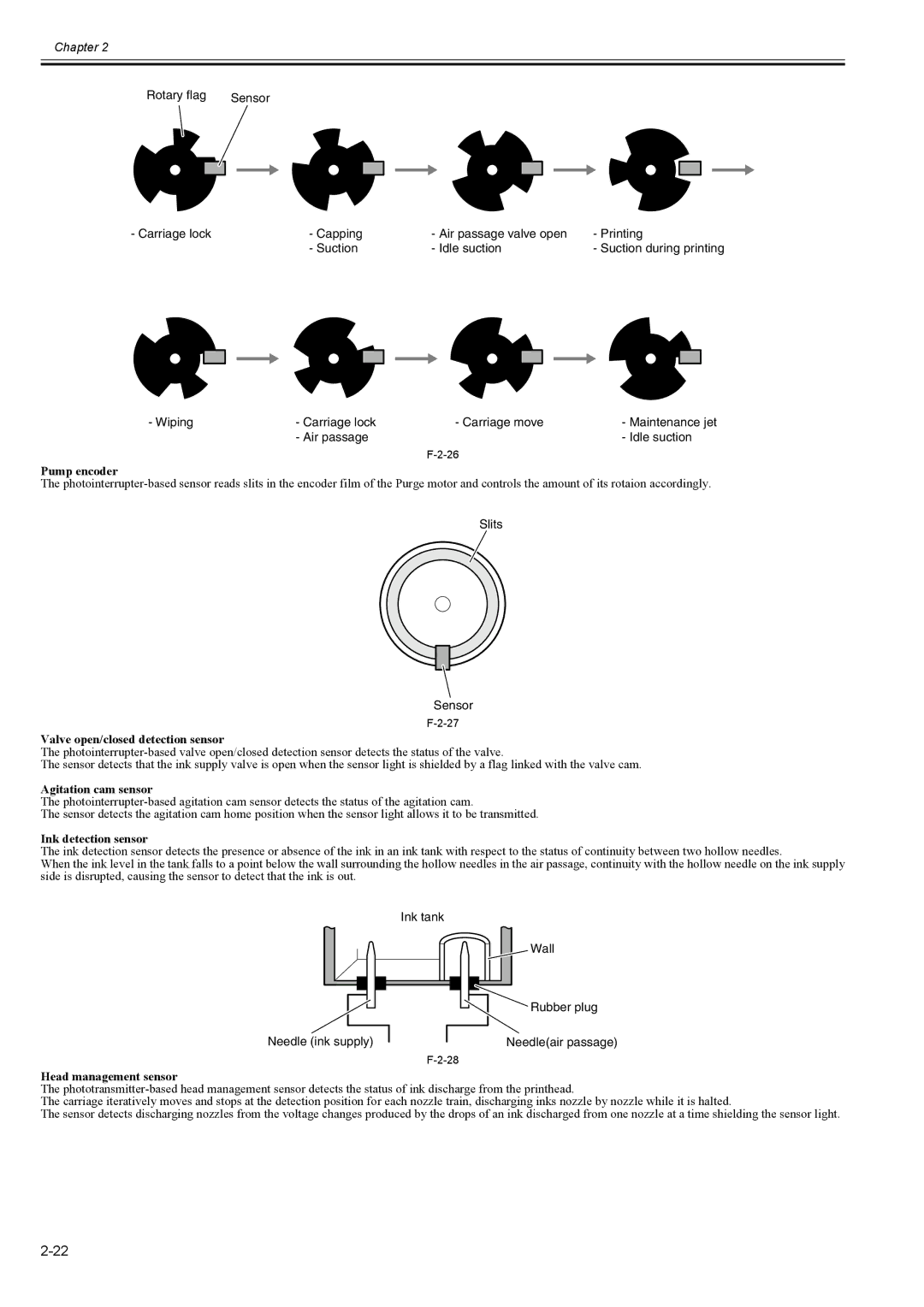

Rotary flag | Sensor | ||

|

|

|

|

|

|

|

|

|

|

|

|

- Carriage lock | - Capping | - Air passage valve open | - Printing |

| - Suction | - Idle suction | - Suction during printing |

- Wiping | - Carriage lock | - Carriage move | - Maintenance jet |

| - Air passage |

| - Idle suction |

Pump encoder

The

Slits

Sensor

Valve open/closed detection sensor

The

The sensor detects that the ink supply valve is open when the sensor light is shielded by a flag linked with the valve cam.

Agitation cam sensor

The

The sensor detects the agitation cam home position when the sensor light allows it to be transmitted.

Ink detection sensor

The ink detection sensor detects the presence or absence of the ink in an ink tank with respect to the status of continuity between two hollow needles.

When the ink level in the tank falls to a point below the wall surrounding the hollow needles in the air passage, continuity with the hollow needle on the ink supply side is disrupted, causing the sensor to detect that the ink is out.

Ink tank

Wall

Needle (ink supply)

Rubber plug

Needle(air passage)

Head management sensor

The

The carriage iteratively moves and stops at the detection position for each nozzle train, discharging inks nozzle by nozzle while it is halted.

The sensor detects discharging nozzles from the voltage changes produced by the drops of an ink discharged from one nozzle at a time shielding the sensor light.