Chapter 2

2.3.3.2 Paper Path

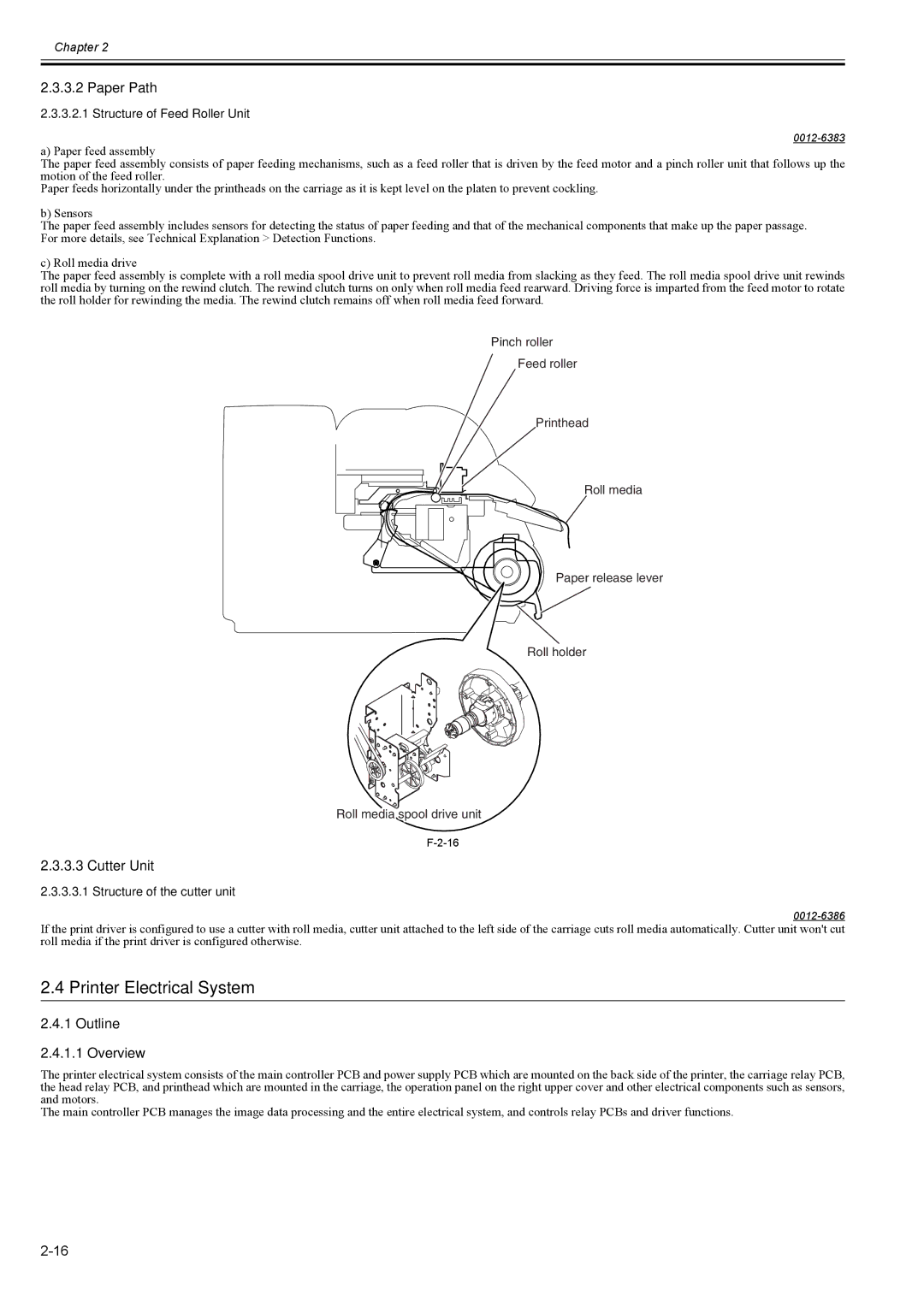

2.3.3.2.1 Structure of Feed Roller Unit

a) Paper feed assembly

The paper feed assembly consists of paper feeding mechanisms, such as a feed roller that is driven by the feed motor and a pinch roller unit that follows up the motion of the feed roller.

Paper feeds horizontally under the printheads on the carriage as it is kept level on the platen to prevent cockling.

b) Sensors

The paper feed assembly includes sensors for detecting the status of paper feeding and that of the mechanical components that make up the paper passage. For more details, see Technical Explanation > Detection Functions.

c) Roll media drive

The paper feed assembly is complete with a roll media spool drive unit to prevent roll media from slacking as they feed. The roll media spool drive unit rewinds roll media by turning on the rewind clutch. The rewind clutch turns on only when roll media feed rearward. Driving force is imparted from the feed motor to rotate the roll holder for rewinding the media. The rewind clutch remains off when roll media feed forward.

Pinch roller

Feed roller

Printhead

Roll media

Paper release lever

Roll holder

Roll media spool drive unit

2.3.3.3 Cutter Unit

2.3.3.3.1 Structure of the cutter unit

If the print driver is configured to use a cutter with roll media, cutter unit attached to the left side of the carriage cuts roll media automatically. Cutter unit won't cut roll media if the print driver is configured otherwise.

2.4 Printer Electrical System

2.4.1 Outline

2.4.1.1 Overview

The printer electrical system consists of the main controller PCB and power supply PCB which are mounted on the back side of the printer, the carriage relay PCB, the head relay PCB, and printhead which are mounted in the carriage, the operation panel on the right upper cover and other electrical components such as sensors, and motors.

The main controller PCB manages the image data processing and the entire electrical system, and controls relay PCBs and driver functions.