Chapter 2

0

2

1

3

0

2

1

3

0

2

1

3

0

2

1

3

0

2

1

3

| 5/600inch | |

0 | 1/1200inch | |

2 | 1 | |

3 | ||

|

2556

2557

2558

2559

2556

2557

2558

2559

2556

2557

2558

2559

2556

2557

2558

2559

2556

2557

2558

2559

2556

2557

2558

2559

82/600inch

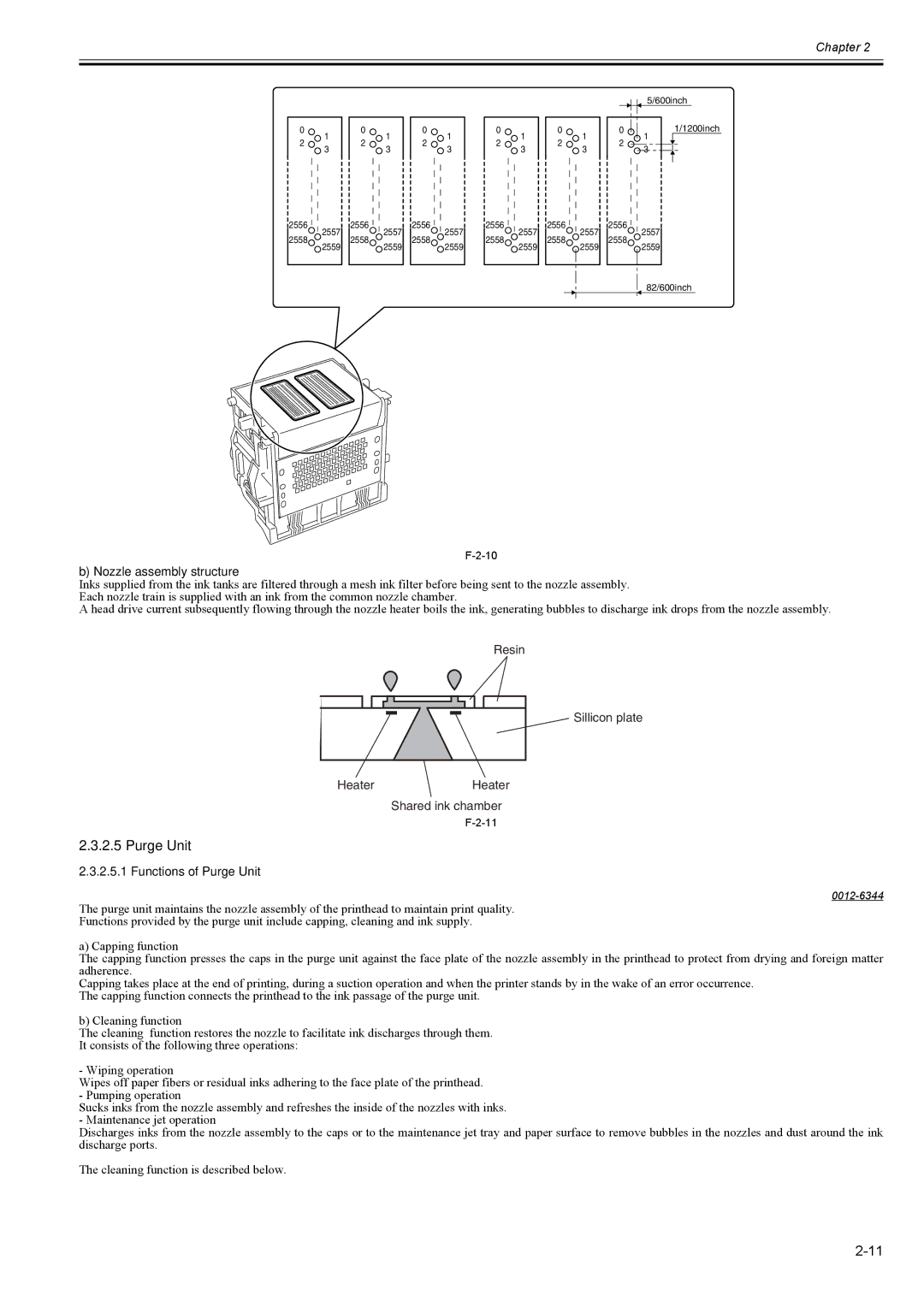

b) Nozzle assembly structure

Inks supplied from the ink tanks are filtered through a mesh ink filter before being sent to the nozzle assembly. Each nozzle train is supplied with an ink from the common nozzle chamber.

A head drive current subsequently flowing through the nozzle heater boils the ink, generating bubbles to discharge ink drops from the nozzle assembly.

Resin

Sillicon plate

HeaterHeater

Shared ink chamber

2.3.2.5 Purge Unit

2.3.2.5.1 Functions of Purge Unit

The purge unit maintains the nozzle assembly of the printhead to maintain print quality.

Functions provided by the purge unit include capping, cleaning and ink supply.

a) Capping function

The capping function presses the caps in the purge unit against the face plate of the nozzle assembly in the printhead to protect from drying and foreign matter adherence.

Capping takes place at the end of printing, during a suction operation and when the printer stands by in the wake of an error occurrence. The capping function connects the printhead to the ink passage of the purge unit.

b) Cleaning function

The cleaning function restores the nozzle to facilitate ink discharges through them. It consists of the following three operations:

- Wiping operation

Wipes off paper fibers or residual inks adhering to the face plate of the printhead. - Pumping operation

Sucks inks from the nozzle assembly and refreshes the inside of the nozzles with inks. - Maintenance jet operation

Discharges inks from the nozzle assembly to the caps or to the maintenance jet tray and paper surface to remove bubbles in the nozzles and dust around the ink discharge ports.

The cleaning function is described below.