Chapter 2

|

| |

|

|

|

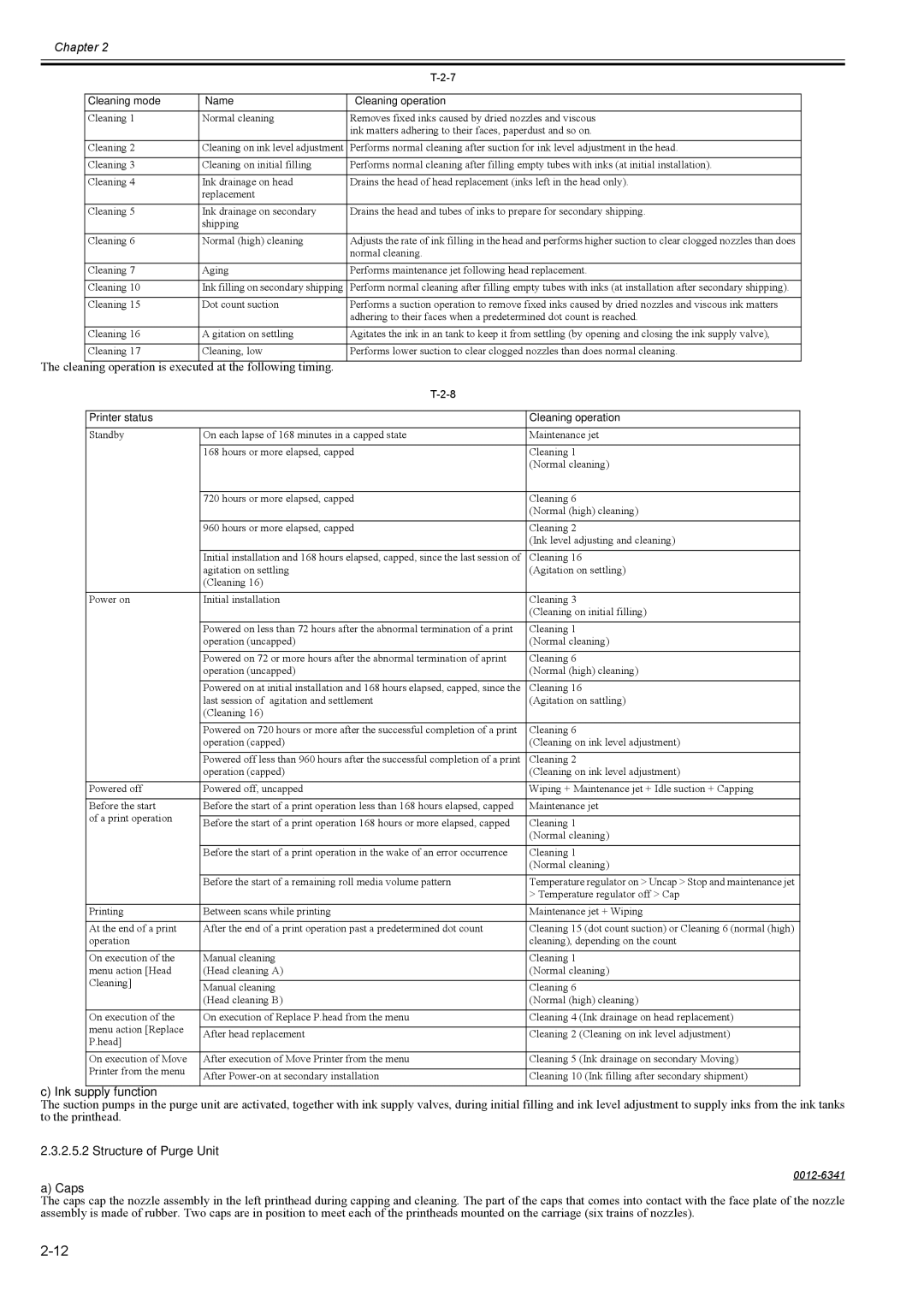

Cleaning mode | Name | Cleaning operation |

|

|

|

Cleaning 1 | Normal cleaning | Removes fixed inks caused by dried nozzles and viscous |

|

| ink matters adhering to their faces, paperdust and so on. |

|

|

|

Cleaning 2 | Cleaning on ink level adjustment | Performs normal cleaning after suction for ink level adjustment in the head. |

|

|

|

Cleaning 3 | Cleaning on initial filling | Performs normal cleaning after filling empty tubes with inks (at initial installation). |

|

|

|

Cleaning 4 | Ink drainage on head | Drains the head of head replacement (inks left in the head only). |

| replacement |

|

|

|

|

Cleaning 5 | Ink drainage on secondary | Drains the head and tubes of inks to prepare for secondary shipping. |

| shipping |

|

|

|

|

Cleaning 6 | Normal (high) cleaning | Adjusts the rate of ink filling in the head and performs higher suction to clear clogged nozzles than does |

|

| normal cleaning. |

|

|

|

Cleaning 7 | Aging | Performs maintenance jet following head replacement. |

|

|

|

Cleaning 10 | Ink filling on secondary shipping | Perform normal cleaning after filling empty tubes with inks (at installation after secondary shipping). |

|

|

|

Cleaning 15 | Dot count suction | Performs a suction operation to remove fixed inks caused by dried nozzles and viscous ink matters |

|

| adhering to their faces when a predetermined dot count is reached. |

|

|

|

Cleaning 16 | A gitation on settling | Agitates the ink in an tank to keep it from settling (by opening and closing the ink supply valve), |

|

|

|

Cleaning 17 | Cleaning, low | Performs lower suction to clear clogged nozzles than does normal cleaning. |

The cleaning operation is executed at the following timing.

|

| ||

|

|

| |

Printer status |

| Cleaning operation | |

|

|

| |

Standby | On each lapse of 168 minutes in a capped state | Maintenance jet | |

|

|

| |

| 168 hours or more elapsed, capped | Cleaning 1 | |

|

| (Normal cleaning) | |

|

|

| |

| 720 hours or more elapsed, capped | Cleaning 6 | |

|

| (Normal (high) cleaning) | |

|

|

| |

| 960 hours or more elapsed, capped | Cleaning 2 | |

|

| (Ink level adjusting and cleaning) | |

|

|

| |

| Initial installation and 168 hours elapsed, capped, since the last session of | Cleaning 16 | |

| agitation on settling | (Agitation on settling) | |

| (Cleaning 16) |

| |

|

|

| |

Power on | Initial installation | Cleaning 3 | |

|

| (Cleaning on initial filling) | |

|

|

| |

| Powered on less than 72 hours after the abnormal termination of a print | Cleaning 1 | |

| operation (uncapped) | (Normal cleaning) | |

|

|

| |

| Powered on 72 or more hours after the abnormal termination of aprint | Cleaning 6 | |

| operation (uncapped) | (Normal (high) cleaning) | |

|

|

| |

| Powered on at initial installation and 168 hours elapsed, capped, since the | Cleaning 16 | |

| last session of agitation and settlement | (Agitation on sattling) | |

| (Cleaning 16) |

| |

|

|

| |

| Powered on 720 hours or more after the successful completion of a print | Cleaning 6 | |

| operation (capped) | (Cleaning on ink level adjustment) | |

|

|

| |

| Powered off less than 960 hours after the successful completion of a print | Cleaning 2 | |

| operation (capped) | (Cleaning on ink level adjustment) | |

|

|

| |

Powered off | Powered off, uncapped | Wiping + Maintenance jet + Idle suction + Capping | |

|

|

| |

Before the start | Before the start of a print operation less than 168 hours elapsed, capped | Maintenance jet | |

of a print operation |

|

| |

Before the start of a print operation 168 hours or more elapsed, capped | Cleaning 1 | ||

|

| (Normal cleaning) | |

|

|

| |

| Before the start of a print operation in the wake of an error occurrence | Cleaning 1 | |

|

| (Normal cleaning) | |

|

|

| |

| Before the start of a remaining roll media volume pattern | Temperature regulator on > Uncap > Stop and maintenance jet | |

|

| > Temperature regulator off > Cap | |

|

|

| |

Printing | Between scans while printing | Maintenance jet + Wiping | |

|

|

| |

At the end of a print | After the end of a print operation past a predetermined dot count | Cleaning 15 (dot count suction) or Cleaning 6 (normal (high) | |

operation |

| cleaning), depending on the count | |

|

|

| |

On execution of the | Manual cleaning | Cleaning 1 | |

menu action [Head | (Head cleaning A) | (Normal cleaning) | |

Cleaning] |

|

| |

Manual cleaning | Cleaning 6 | ||

| |||

| (Head cleaning B) | (Normal (high) cleaning) | |

|

|

| |

On execution of the | On execution of Replace P.head from the menu | Cleaning 4 (Ink drainage on head replacement) | |

menu action [Replace |

|

| |

After head replacement | Cleaning 2 (Cleaning on ink level adjustment) | ||

P.head] | |||

|

| ||

|

|

| |

On execution of Move | After execution of Move Printer from the menu | Cleaning 5 (Ink drainage on secondary Moving) | |

Printer from the menu |

|

| |

After | Cleaning 10 (Ink filling after secondary shipment) | ||

|

c) Ink supply function

The suction pumps in the purge unit are activated, together with ink supply valves, during initial filling and ink level adjustment to supply inks from the ink tanks to the printhead.

2.3.2.5.2 Structure of Purge Unit

a) Caps

The caps cap the nozzle assembly in the left printhead during capping and cleaning. The part of the caps that comes into contact with the face plate of the nozzle assembly is made of rubber. Two caps are in position to meet each of the printheads mounted on the carriage (six trains of nozzles).