Chapter 2

Carriage unit

![]() Mechanical Drive Unit

Mechanical Drive Unit ![]() Ink or air flow

Ink or air flow

Printhead | Joint |

| |

| Ink tank |

| |

Cap |

|

| |

Needle(ink supply) | Needle(air passage) | ||

Suction pump |

| ||

|

| ||

Ink supply vavle |

|

| |

|

| Piston | |

|

| Agitation fin | |

Joint |

|

| |

Valve | Agitation | Sub buffer | |

motor | cam | ||

| |||

Maintenance cartridge

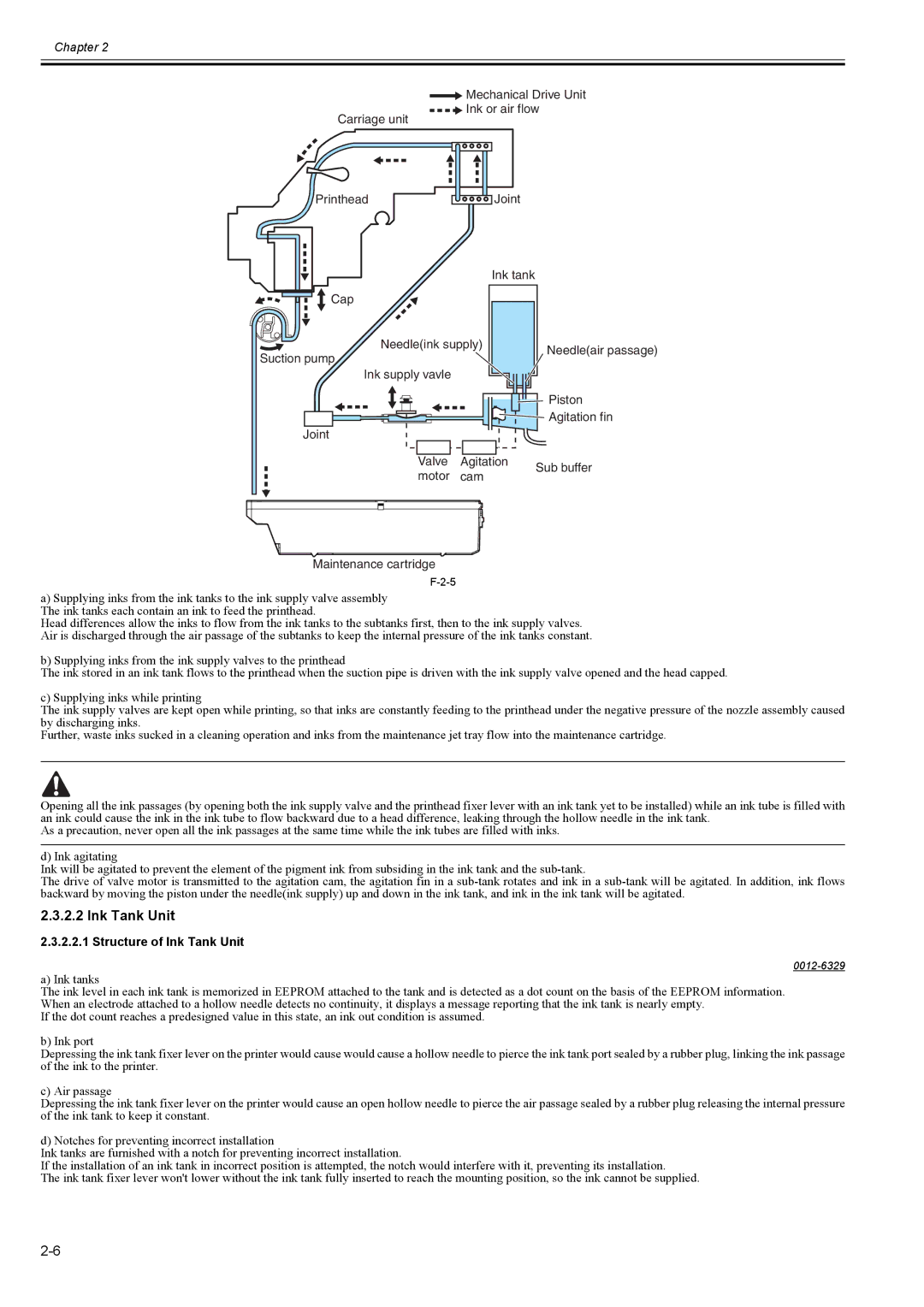

a)Supplying inks from the ink tanks to the ink supply valve assembly The ink tanks each contain an ink to feed the printhead.

Head differences allow the inks to flow from the ink tanks to the subtanks first, then to the ink supply valves. Air is discharged through the air passage of the subtanks to keep the internal pressure of the ink tanks constant.

b)Supplying inks from the ink supply valves to the printhead

The ink stored in an ink tank flows to the printhead when the suction pipe is driven with the ink supply valve opened and the head capped.

c) Supplying inks while printing

The ink supply valves are kept open while printing, so that inks are constantly feeding to the printhead under the negative pressure of the nozzle assembly caused by discharging inks.

Further, waste inks sucked in a cleaning operation and inks from the maintenance jet tray flow into the maintenance cartridge.

Opening all the ink passages (by opening both the ink supply valve and the printhead fixer lever with an ink tank yet to be installed) while an ink tube is filled with an ink could cause the ink in the ink tube to flow backward due to a head difference, leaking through the hollow needle in the ink tank.

As a precaution, never open all the ink passages at the same time while the ink tubes are filled with inks.

d) Ink agitating

Ink will be agitated to prevent the element of the pigment ink from subsiding in the ink tank and the

The drive of valve motor is transmitted to the agitation cam, the agitation fin in a

2.3.2.2 Ink Tank Unit

2.3.2.2.1 Structure of Ink Tank Unit

a) Ink tanks

The ink level in each ink tank is memorized in EEPROM attached to the tank and is detected as a dot count on the basis of the EEPROM information. When an electrode attached to a hollow needle detects no continuity, it displays a message reporting that the ink tank is nearly empty.

If the dot count reaches a predesigned value in this state, an ink out condition is assumed.

b) Ink port

Depressing the ink tank fixer lever on the printer would cause would cause a hollow needle to pierce the ink tank port sealed by a rubber plug, linking the ink passage of the ink to the printer.

c) Air passage

Depressing the ink tank fixer lever on the printer would cause an open hollow needle to pierce the air passage sealed by a rubber plug releasing the internal pressure of the ink tank to keep it constant.

d) Notches for preventing incorrect installation

Ink tanks are furnished with a notch for preventing incorrect installation.

If the installation of an ink tank in incorrect position is attempted, the notch would interfere with it, preventing its installation.

The ink tank fixer lever won't lower without the ink tank fully inserted to reach the mounting position, so the ink cannot be supplied.