Troubleshooting continued

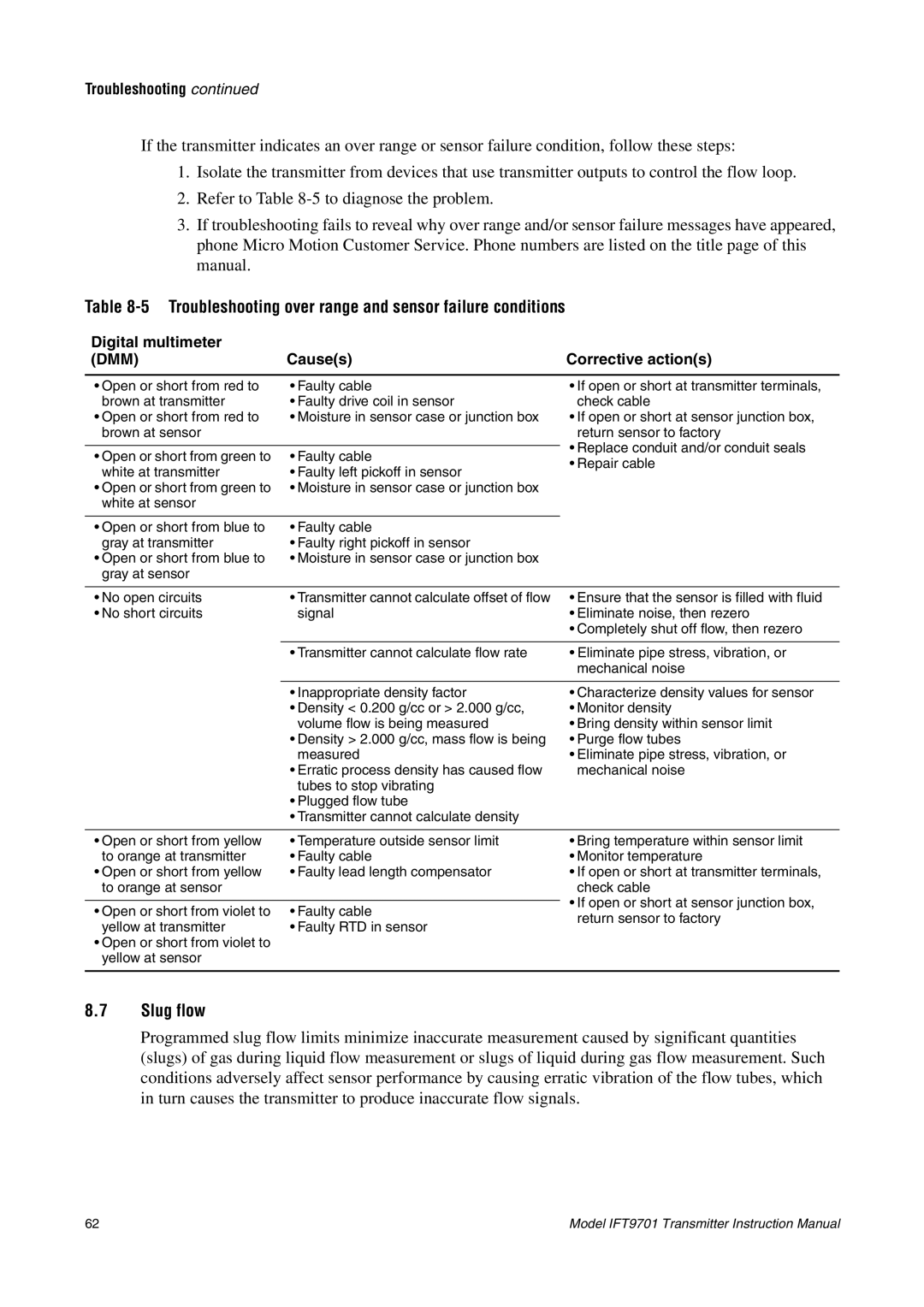

If the transmitter indicates an over range or sensor failure condition, follow these steps:

1.Isolate the transmitter from devices that use transmitter outputs to control the flow loop.

2.Refer to Table

3.If troubleshooting fails to reveal why over range and/or sensor failure messages have appeared, phone Micro Motion Customer Service. Phone numbers are listed on the title page of this manual.

Table 8-5 Troubleshooting over range and sensor failure conditions

Digital multimeter |

|

|

(DMM) | Cause(s) | Corrective action(s) |

• Open or short from red to | • Faulty cable |

brown at transmitter | • Faulty drive coil in sensor |

• Open or short from red to | • Moisture in sensor case or junction box |

brown at sensor |

|

|

|

• Open or short from green to | • Faulty cable |

white at transmitter | • Faulty left pickoff in sensor |

• Open or short from green to | • Moisture in sensor case or junction box |

white at sensor |

|

•If open or short at transmitter terminals, check cable

•If open or short at sensor junction box, return sensor to factory

•Replace conduit and/or conduit seals

•Repair cable

• Open or short from blue to | • Faulty cable |

|

gray at transmitter | • Faulty right pickoff in sensor |

|

• Open or short from blue to | • Moisture in sensor case or junction box |

|

gray at sensor |

|

|

|

|

|

• No open circuits | • Transmitter cannot calculate offset of flow | • Ensure that the sensor is filled with fluid |

• No short circuits | signal | • Eliminate noise, then rezero |

|

| • Completely shut off flow, then rezero |

|

|

|

| • Transmitter cannot calculate flow rate | • Eliminate pipe stress, vibration, or |

|

| mechanical noise |

•Inappropriate density factor

•Density < 0.200 g/cc or > 2.000 g/cc, volume flow is being measured

•Density > 2.000 g/cc, mass flow is being measured

•Erratic process density has caused flow tubes to stop vibrating

•Plugged flow tube

•Transmitter cannot calculate density

•Characterize density values for sensor

•Monitor density

•Bring density within sensor limit

•Purge flow tubes

•Eliminate pipe stress, vibration, or mechanical noise

• Open or short from yellow | • Temperature outside sensor limit |

to orange at transmitter | • Faulty cable |

• Open or short from yellow | • Faulty lead length compensator |

to orange at sensor |

|

|

|

• Open or short from violet to | • Faulty cable |

yellow at transmitter | • Faulty RTD in sensor |

• Open or short from violet to |

|

yellow at sensor |

|

•Bring temperature within sensor limit

•Monitor temperature

•If open or short at transmitter terminals, check cable

•If open or short at sensor junction box, return sensor to factory

8.7Slug flow

Programmed slug flow limits minimize inaccurate measurement caused by significant quantities (slugs) of gas during liquid flow measurement or slugs of liquid during gas flow measurement. Such conditions adversely affect sensor performance by causing erratic vibration of the flow tubes, which in turn causes the transmitter to produce inaccurate flow signals.

62 | Model IFT9701 Transmitter Instruction Manual |