Setup & Operation 1. Safety

1.4 Emergency Stop

If the Manipulator moves abnormally during operation, immediately press the Emergency Stop switch. Stops the power supply to the motor, and the arm stops in the shortest distance with the dynamic brake and mechanical brake.

However, avoid pressing the Emergency Stop switch unnecessarily while the Manipulator is running normally. Otherwise, the Manipulator may hit the peripheral equipment since the operating trajectory while the robot system stops is different from that in normal operation.

To place the system in emergency mode during normal operation, press the Emergency Stop switch when the Manipulator is not moving.

Refer to the Controller manual for instructions on how to wire the Emergency Stop switch circuit.

Free running distance in emergency

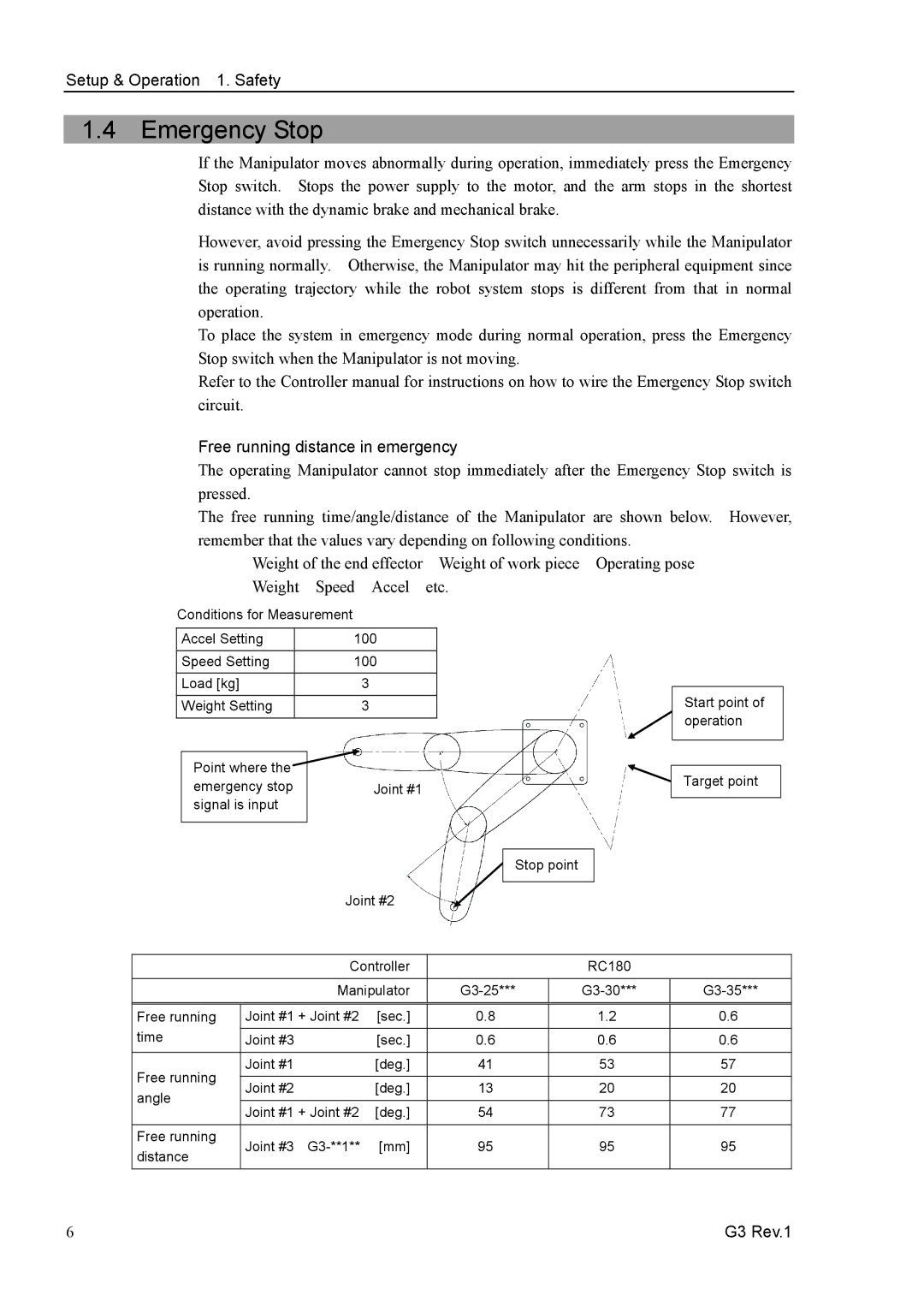

The operating Manipulator cannot stop immediately after the Emergency Stop switch is pressed.

The free running time/angle/distance of the Manipulator are shown below. However, remember that the values vary depending on following conditions.

Weight of the end effector Weight of work piece Operating pose Weight Speed Accel etc.

Conditions for Measurement

| Accel Setting | 100 | |

|

|

|

|

| Speed Setting | 100 | |

|

|

|

|

| Load [kg] | 3 | |

|

|

|

|

| Weight Setting | 3 | |

|

|

|

|

|

|

|

|

| Point where the |

|

|

| emergency stop |

| Joint #1 |

| signal is input |

|

|

|

|

|

|

Joint #2

Start point of operation

![]() Target point

Target point

Stop point

| Controller |

| RC180 |

| ||

|

|

|

|

| ||

| Manipulator | |||||

|

|

|

|

|

| |

Free running | Joint #1 + Joint #2 | [sec.] | 0.8 | 1.2 | 0.6 | |

time | Joint #3 | [sec.] | 0.6 | 0.6 | 0.6 | |

|

|

|

|

|

| |

Free running | Joint #1 | [deg.] | 41 | 53 | 57 | |

|

|

|

|

| ||

Joint #2 | [deg.] | 13 | 20 | 20 | ||

angle | ||||||

|

|

|

|

| ||

Joint #1 + Joint #2 | [deg.] | 54 | 73 | 77 | ||

| ||||||

|

|

|

|

|

| |

Free running | Joint #3 | [mm] | 95 | 95 | 95 | |

distance | ||||||

|

|

|

|

| ||

|

|

|

|

|

| |

6 | G3 Rev.1 |