Maintenance 1. Safety Maintenance

CAUTION

■Be sure to connect the cables properly. Do not allow unnecessary strain on the cables. (Do not put heavy objects on the cables. Do not bend or pull the cables forcibly.) The unnecessary strain on the cables may result in damage to the cables, disconnection, and/or contact failure. Damaged cables, disconnection, or contact failure is extremely hazardous and may result in electric shock and/or improper function of the robot system.

2.General Maintenance

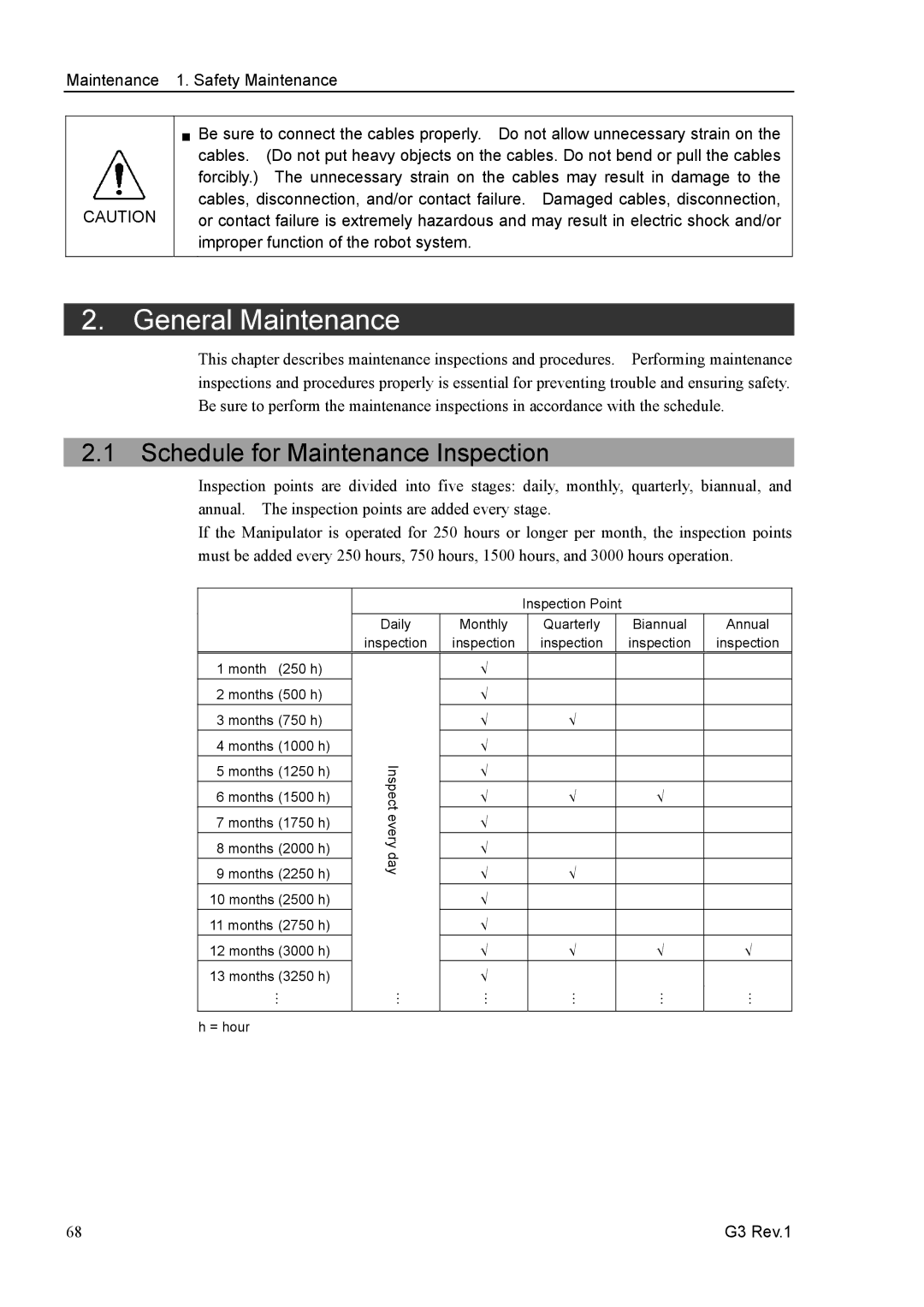

This chapter describes maintenance inspections and procedures. Performing maintenance inspections and procedures properly is essential for preventing trouble and ensuring safety. Be sure to perform the maintenance inspections in accordance with the schedule.

2.1 Schedule for Maintenance Inspection

Inspection points are divided into five stages: daily, monthly, quarterly, biannual, and annual. The inspection points are added every stage.

If the Manipulator is operated for 250 hours or longer per month, the inspection points must be added every 250 hours, 750 hours, 1500 hours, and 3000 hours operation.

|

|

|

| Inspection Point |

|

| ||

|

| Daily | Monthly |

| Quarterly |

| Biannual | Annual |

|

| inspection | inspection |

| inspection |

| inspection | inspection |

1 month | (250 h) |

| √ |

|

|

|

|

|

2 months | (500 h) |

| √ |

|

|

|

|

|

3 months | (750 h) |

| √ |

| √ |

|

|

|

4 months | (1000 h) |

| √ |

|

|

|

|

|

5 months | (1250 h) | Inspect | √ |

|

|

|

|

|

6 months | (1500 h) | √ |

| √ |

| √ |

| |

|

|

|

| |||||

7 months | (1750 h) | every | √ |

|

|

|

|

|

|

|

|

|

|

| |||

8 months | (2000 h) | day | √ |

|

|

|

|

|

9 months | (2250 h) | √ |

| √ |

|

|

| |

|

|

|

|

| ||||

10 months | (2500 h) |

| √ |

|

|

|

|

|

11 months | (2750 h) |

| √ |

|

|

|

|

|

12 months | (3000 h) |

| √ |

| √ |

| √ | √ |

13 months | (3250 h) |

| √ |

|

|

|

|

|

… |

| … | … |

| … |

| … | … |

|

|

|

|

|

|

|

|

|

h = hour

68 | G3 Rev.1 |