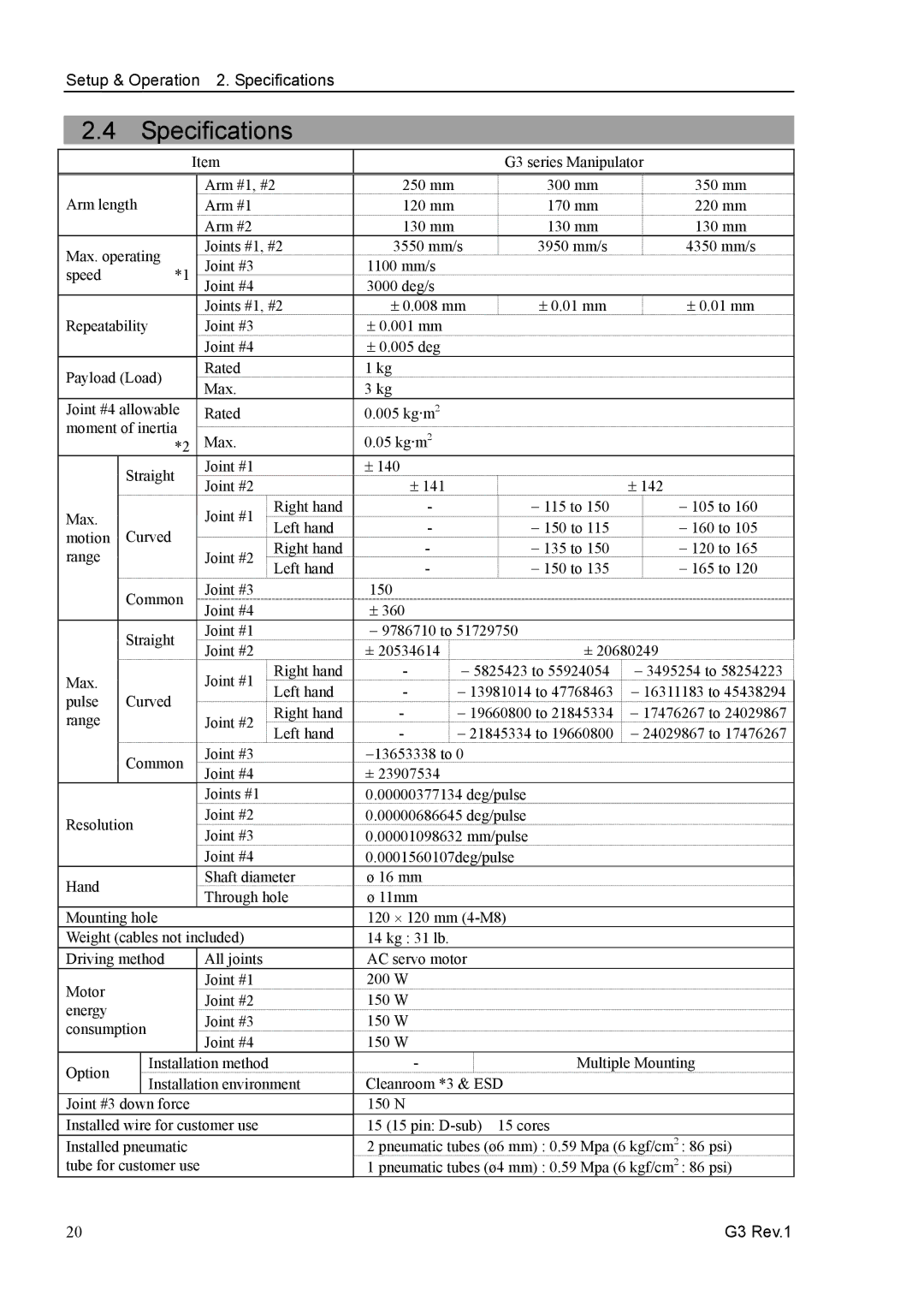

Setup & Operation 2. Specifications

| 2.4 |

| Specifications |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

| Item |

|

|

|

| G3 series Manipulator | |||

| Arm length |

| Arm #1, #2 | 250 mm |

|

| 300 mm |

| 350 mm | |||

|

| Arm #1 |

| 120 mm |

|

| 170 mm |

| 220 mm | |||

|

|

|

|

| Arm #2 |

| 130 mm |

|

| 130 mm |

| 130 mm |

| Max. operating |

| Joints #1, #2 | 3550 mm/s |

| 3950 mm/s |

| 4350 mm/s | ||||

|

| Joint #3 |

| 1100 mm/s |

|

|

|

|

| |||

| speed | *1 |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| ||||||

|

|

|

|

| Joint #4 |

| 3000 deg/s |

|

|

|

|

|

|

|

|

|

| Joints #1, #2 | ± 0.008 mm |

| ± 0.01 mm |

| ± 0.01 mm | ||

| Repeatability |

| Joint #3 |

| ± 0.001 mm |

|

|

|

|

| ||

|

|

|

|

| Joint #4 |

| ± 0.005 deg |

|

|

|

|

|

| Payload (Load) |

| Rated |

| 1 kg |

|

|

|

|

| ||

|

| Max. |

| 3 kg |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| ||

| Joint #4 allowable |

| Rated |

| 0.005 kg·m2 |

|

|

|

|

| ||

| moment of inertia |

| Max. |

| 0.05 kg·m2 |

|

|

|

|

| ||

|

|

|

|

|

|

|

| |||||

|

| *2 |

|

|

|

|

|

|

| |||

|

| Straight |

| Joint #1 |

| ± 140 |

|

|

|

|

| |

|

|

| Joint #2 |

| ± 141 |

|

|

| ± 142 | |||

|

|

|

|

|

|

|

|

| ||||

| Max. |

|

|

| Joint #1 | Right hand | - |

|

| − 115 to 150 |

| − 105 to 160 |

| Curved |

| Left hand | - |

|

| − 150 to 115 |

| − 160 to 105 | |||

| motion |

|

|

|

|

| ||||||

|

|

| Right hand | - |

|

| − 135 to 150 |

| − 120 to 165 | |||

| range |

|

|

| Joint #2 |

|

|

| ||||

|

|

|

| Left hand | - |

|

| − 150 to 135 |

| − 165 to 120 | ||

|

|

|

|

|

|

|

|

| ||||

|

| Common |

| Joint #3 |

| 150 |

|

|

|

|

| |

|

|

| Joint #4 |

| ± 360 |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| ||

|

| Straight |

| Joint #1 |

| − 9786710 to 51729750 |

|

| ||||

|

|

| Joint #2 |

| ± 20534614 |

| ± 20680249 | |||||

|

|

|

|

|

|

| ||||||

| Max. |

|

|

| Joint #1 | Right hand | - | − 5825423 to 55924054 | − 3495254 to 58254223 | |||

| Curved |

| Left hand | - | − 13981014 to 47768463 | − 16311183 to 45438294 | ||||||

| pulse |

|

| |||||||||

|

|

| Right hand | - | − 19660800 to 21845334 | − 17476267 to 24029867 | ||||||

| range |

|

|

| Joint #2 | |||||||

|

|

|

| Left hand | - | − 21845334 to 19660800 | − 24029867 to 17476267 | |||||

|

|

|

|

|

| |||||||

|

| Common |

| Joint #3 |

| −13653338 to 0 |

|

|

|

| ||

|

|

| Joint #4 |

| ± 23907534 |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| Joints #1 |

| 0.00000377134 deg/pulse |

|

| |||

| Resolution |

| Joint #2 |

| 0.00000686645 deg/pulse |

|

| |||||

|

| Joint #3 |

| 0.00001098632 mm/pulse |

|

| ||||||

|

|

|

|

|

|

|

| |||||

|

|

|

|

| Joint #4 |

| 0.0001560107deg/pulse |

|

| |||

| Hand |

|

|

| Shaft diameter | ø 16 mm |

|

|

|

|

| |

|

|

|

| Through hole | ø 11mm |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |||

| Mounting hole |

|

|

| 120 ⋅ 120 mm |

|

| |||||

| Weight (cables not included) |

| 14 kg : 31 lb. |

|

|

|

|

| ||||

| Driving method |

| All joints |

| AC servo motor |

|

|

|

| |||

| Motor |

|

|

| Joint #1 |

| 200 W |

|

|

|

|

|

|

|

|

| Joint #2 |

| 150 W |

|

|

|

|

| |

| energy |

|

|

|

|

|

|

|

|

| ||

|

|

|

| Joint #3 |

| 150 W |

|

|

|

|

| |

| consumption |

|

|

|

|

|

|

| ||||

|

| Joint #4 |

| 150 W |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| ||

| Option |

| Installation method |

| - |

|

| Multiple Mounting | ||||

|

| Installation environment | Cleanroom *3 & ESD |

|

| |||||||

|

|

|

|

| ||||||||

| Joint #3 down force |

|

|

| 150 N |

|

|

|

|

| ||

| Installed wire for customer use |

| 15 (15 pin: | 15 cores |

|

| ||||||

| Installed pneumatic |

|

|

| 2 pneumatic tubes (ø6 mm) : 0.59 Mpa (6 kgf/cm2 : 86 psi) | |||||||

| tube for customer use |

| 1 pneumatic tubes (ø4 mm) : 0.59 Mpa (6 kgf/cm2 : 86 psi) | |||||||||

20 | G3 Rev.1 |