Maintenance 2. General Maintenance

2.3 Greasing

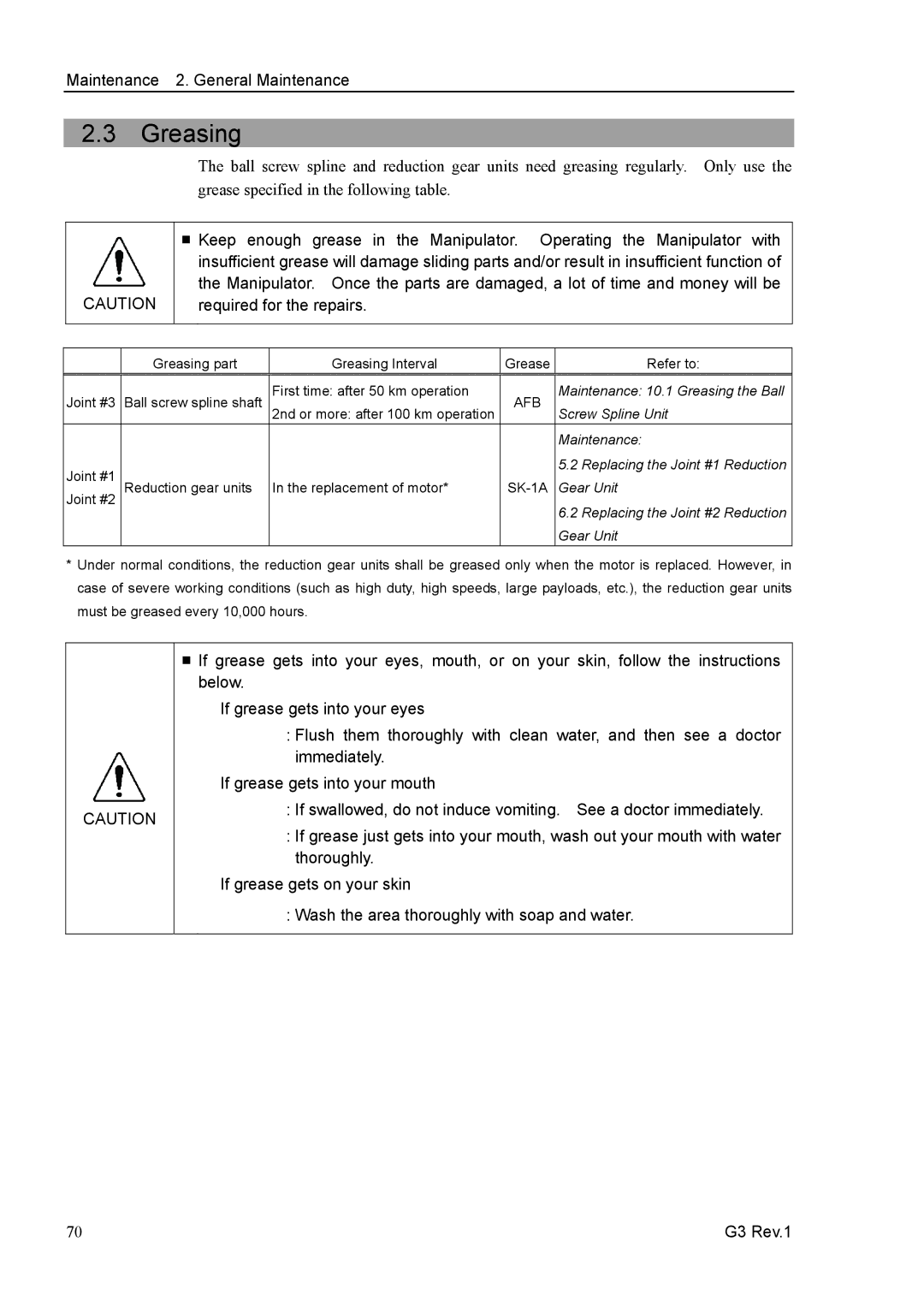

The ball screw spline and reduction gear units need greasing regularly. Only use the grease specified in the following table.

CAUTION

■Keep enough grease in the Manipulator. Operating the Manipulator with insufficient grease will damage sliding parts and/or result in insufficient function of the Manipulator. Once the parts are damaged, a lot of time and money will be required for the repairs.

| Greasing part | Greasing Interval | Grease | Refer to: | |

Joint #3 | Ball screw spline shaft | First time: after 50 km operation | AFB | Maintenance: 10.1 Greasing the Ball | |

|

| 2nd or more: after 100 km operation |

| Screw Spline Unit | |

|

|

|

| Maintenance: | |

Joint #1 |

|

|

| 5.2 Replacing the Joint #1 Reduction | |

Reduction gear units | In the replacement of motor* | Gear Unit | |||

Joint #2 | |||||

|

|

|

| 6.2 Replacing the Joint #2 Reduction | |

|

|

|

| Gear Unit |

*Under normal conditions, the reduction gear units shall be greased only when the motor is replaced. However, in case of severe working conditions (such as high duty, high speeds, large payloads, etc.), the reduction gear units must be greased every 10,000 hours.

CAUTION

■If grease gets into your eyes, mouth, or on your skin, follow the instructions below.

If grease gets into your eyes

:Flush them thoroughly with clean water, and then see a doctor immediately.

If grease gets into your mouth

:If swallowed, do not induce vomiting. See a doctor immediately.

:If grease just gets into your mouth, wash out your mouth with water thoroughly.

If grease gets on your skin

: Wash the area thoroughly with soap and water.

70 | G3 Rev.1 |