18

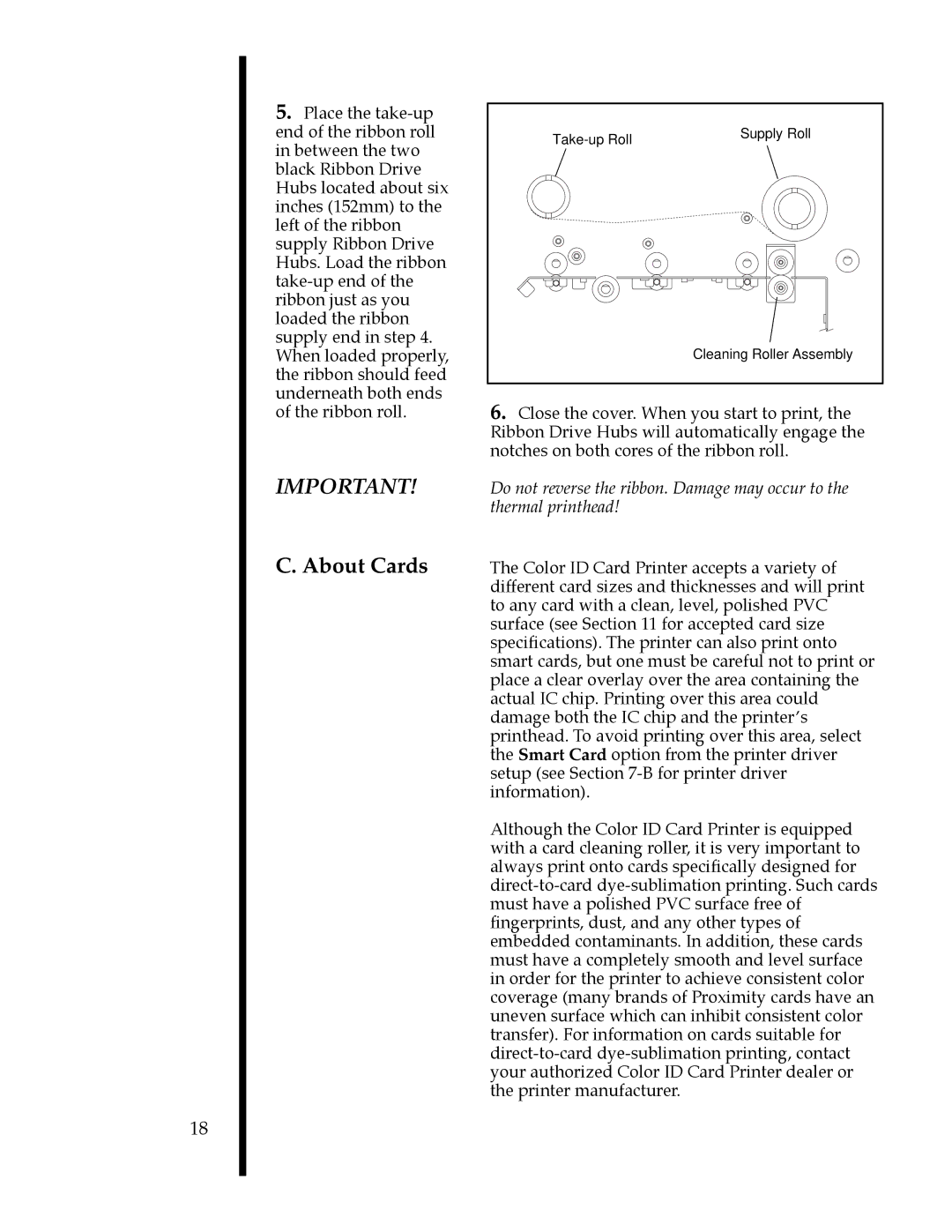

5.Place the

IMPORTANT!

C. About Cards

Supply Roll | |

| |

| Cleaning Roller Assembly |

6.Close the cover. When you start to print, the Ribbon Drive Hubs will automatically engage the notches on both cores of the ribbon roll.

Do not reverse the ribbon. Damage may occur to the thermal printhead!

The Color ID Card Printer accepts a variety of different card sizes and thicknesses and will print to any card with a clean, level, polished PVC surface (see Section 11 for accepted card size specifications). The printer can also print onto smart cards, but one must be careful not to print or place a clear overlay over the area containing the actual IC chip. Printing over this area could damage both the IC chip and the printerÕs printhead. To avoid printing over this area, select the Smart Card option from the printer driver setup (see Section

Although the Color ID Card Printer is equipped with a card cleaning roller, it is very important to always print onto cards specifically designed for