HP LaserJet P2050 and P2030 Series Printers

Page

Page

Copyright and License

Trademark Credits

Table of contents

Control panel

Paper and print media

Manage and maintain

Removal and replacement

Theory of operation

Solve problems

Enww

Parts and diagrams

Appendix C Regulatory information

Appendix a Service and support

Appendix B Specifications

301

Product basics

HP LaserJet P2055d printer HP LaserJet P2055dn printer

Product comparison

HP LaserJet P2050 Series Printers

CE457A CE459A CE460A

HP LaserJet P2035 printer

HP LaserJet P2030 Series Printers

CE461A CE462A

Product features

Feature Description

Button, 6 LED control panel

Product walkaround

Front view

Rear view

Interface ports

Model and serial number label

HP LaserJet P2030 Series Printers

Rear view

1HP LaserJet P2035 printer

Model and serial-number label location

Software included with the product

Software installation types for Windows

Supported product software

Macintosh software

Software for Windows

HP Web Jetadmin

Other software provided

Software for networks

Software for other operating systems

Software

Windows requirements

System minimum requirements

Macintosh requirements

Supported networks HP LaserJet P2050 Series Printers

Service name Description

Connectivity

2Network product discovery

Supported network HP LaserJet P2030 Series Printers

4IP addressing

7Messaging and management

6Network product discovery

8IP addressing

Product basics

Control panel

Control-panel layout

Control panel HP LaserJet P2050 Series Printers only

Number Button or light Function

Use the control-panel menus

Use the menus

Reports menu

Menu item Description

System setup menu

Menu item Sub-menu item Description

Control panel

Service menu

Use this menu to establish network configuration settings

WEB

Control panel HP LaserJet P2030 Series Printers only

Go button and light

Paper and print media

Paper for the HP LaserJet P2050 Series Printers

Size and dimensions Tray Optional 500-sheet Duplexer

Supported paper and print media

Supported paper and print media sizes

Supported paper and print media types

Tray and bin capacity

Tray or bin Paper type Specifications Quantity

Paper for the HP LaserJet P2030 Series Printers

Recycled

Size and dimensions Tray

2Supported paper and print media sizes

Paper type printer driver Tray

Tray and bin capacity

Load trays

Load paper and print media

Paper orientation for loading trays

Tray

Load A6-size paper

Optional Tray 3 HP LaserJet P2050 Series Printers only

Manual feed

Configure trays HP LaserJet P2050 Series Printers only

Configure trays

Configure trays HP LaserJet P2030 Series Printers only

Use paper output options

Print to the top standard output bin

Print to the straight-through paper path rear output

Paper and print media

Manage and maintain

Print the information pages

Print the information pages

Demo

Name of report Description

Configuration

Supplies Status

View HP ToolboxFX

Status

Event log

Alerts

Set up Status Alerts

Set up E-mail Alerts

Help

Device Settings

Device Information

PCL5c

Paper Handling

Printing

PostScript

Shop for Supplies

Network Settings

Other Links

Enww

Open the embedded Web server

Manage a network product

Status tab

Use HP Web Jetadmin software

Use security features

Supplies life

Manage supplies

Manage the print cartridge

Enww

Replace supplies and parts

Supply replacement guidelines

Redistribute toner

Change the print cartridge

Enww

Install memory HP LaserJet P2050 Series Printers only

Install product memory

Install memory HP LaserJet P2050 Series Printers only

Enww

Check Dimm installation

Save resources permanent resources

Enable memory for Windows

Click the Device Settings tab

Clean the product

Clean the print-cartridge area

Clean the paper path HP LaserJet P2050 Series Printers only

Clean the paper path HP LaserJet P2030 Series Printers only

Clean the Tray 1 pickup roller

Settings tab

Enww

Enww

Enww

Clean the Tray 2 pickup roller

Enww

Reconnect the power cord, and turn the product on

Manage and maintain

Theory of operation

1Block diagram

Introduction

Internal components

2Cross-section of product

Enww

1Sequence of operation

Timing

Name Timing Purpose

Engine control system

3Engine control system

DC controller

4DC controller

Low-voltage power supply

Swon

High-voltage power supply

6High-voltage power supply

Laser/scanner system

7Laser/scanner system

Laser failure detection

Image-formation system

Primary charging

10 Developing

11 Transfer

13 Fusing

Pickup/feed/delivery system

Pickup/feed/delivery system

Jam detection

16Jam detection

Enww

Removal and replacement

Removal and replacement strategy

Electrostatic discharge

Required tools

1Phillips and pozidrive screwdriver comparison

Before performing service

After performing service

Post-service test

Print-quality test

Print cartridge

Tray 2 cassette

3Remove the Tray 2 cassette

Rollers and pads

Pickup roller Tray

Release two tabs

8Remove the pickup roller Tray 1 5 Removal and replacement

Pickup roller assembly Tray

9Remove the pickup roller assembly Tray 2 1

Enww

13Remove the pickup roller Tray 2 5

Separation-pad assembly Tray

14Remove the separation-pad assembly Tray 2 1

Transfer roller

19Remove the transfer roller 4 Removal and replacement

20Remove the transfer roller 5

External panels, covers, and doors

Dimm door HP LaserJet P2050 Series only

Right cover

26Remove the right cover 4 Removal and replacement

Reinstall the right cover

Left cover

Enww

Rear cover, rear door, and duplex-paper-feed assembly

Remove five screws callout

Enww

Enww

Top-cover assembly

Enww

Remove three screws callout

Cartridge-door assembly and front cover

44Remove the cartridge door assembly and front cover 2

Carefully remove the cartridge-door assembly

Reinstall the cartridge-door assembly and front cover

Internal assemblies

Formatter PCA HP LaserJet P2030 Series

Internal assemblies

Formatter PCA HP LaserJet P2050 Series

Enww

Paper-pickup-gear assembly

Reinstall the paper-pickup-gear assembly

55Remove the paper-pickup-gear assembly 3

Enww

Cartridge-door switch

Tray 1 pickup solenoid

Enww

Fan

65Remove the fan 3

Reverse-sensor assembly HP LaserJet P2050 Series

Remove the reverse-sensor assembly

Power-switch assembly

68Remove the power-switch assembly 1 Removal and replacement

70Remove the power-switch assembly 3

71Remove the power-switch assembly 4 Removal and replacement

Connecting PCA

72Remove the connecting PCA 1

Enww

75Remove the connecting PCA 4

Inlet-cable assembly

76Remove the inlet-cable assembly 1 Removal and replacement

78Remove the inlet-cable assembly 3

Registration assembly

Top cover assembly. See Top-cover assembly on

80Remove the registration assembly 2 Remove the guide

Enww

85Remove the registration assembly 7

Laser/scanner assembly

87Remove the laser/scanner assembly 2

88Remove the fuser 1 Removal and replacement

Fuser

Enww

Enww

94Remove the fuser 7

Reinstall the fuser

Engine controller unit ECU

Enww

101Remove the ECU 5

Enww

Enww

107Remove the ECU 11 Removal and replacement

109Remove the ECU 13

Reinstall the ECU

111Reinstall the fuser 1 Removal and replacement

Enww

Paper-feed-guide assembly

114Remove the paper-feed-guide assembly 2

Main motor

117Remove the main motor 3

118Remove the main motor 4

Face-down-drive or duplexing-paper-feed assembly

Remove the fan duct

Remove the face-down-drive or duplexing-paper-feed assembly

Duplex solenoid HP LaserJet P2050 Series

Paper-retaining-delivery assembly

125Remove the paper-retaining-delivery assembly 1

Enww

Enww

Remove the paper-retaining-delivery assembly

Solve problems

Solve general problems

Troubleshooting checklist

Factors that affect product performance

1Basic problem solving

Basic problem solving

Problem Cause Solution

Engine components

Engine test page on

Menu map HP LaserJet P2050 Series Printers only

Print a menu map

Pre-troubleshooting checklist

Troubleshooting process

General topic Questions

For 10 to 20 minutes

Half self-test functional check

Tools for troubleshooting

Continuous self-test HP LaserJet P2050 Series only

Drum rotation functional check

High-voltage contacts check

Heating element check

Checking the print cartridge contacts

1High-voltage contact points on the print cartridge

2Left-side components

Component locations

Reference Component Description If disconnected or blocked

3Right-side components

FM1

4Connector PCA components

Reference Component Description

Output bin appears

5Rear-side components

6Print cartridge components

Cartridge area appears

7Top components

Bin full appears

8Tray 1 and Tray 2 components

9Repetitive defects

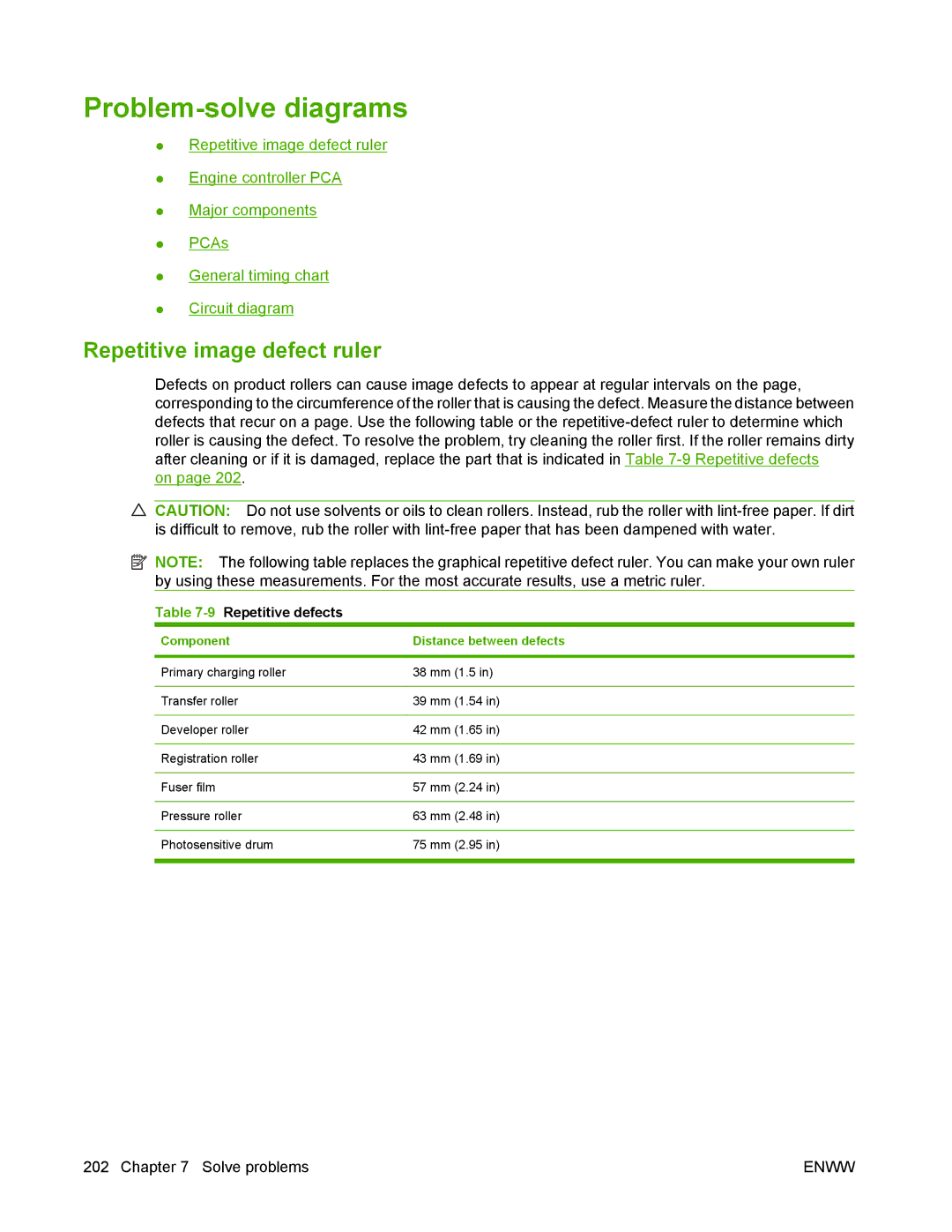

Problem-solve diagrams

Repetitive image defect ruler

Component Distance between defects

Description When disconnected

10Engine controller connectors

Engine controller PCA

Control-panel messageLoad paper appears

Supply memory error appears

Open door and clear jam appear

Major components

11Major components

PCAs

12 PCAs

Timing chart

Chart

General

Circuit diagram

Circuit diagram

14Control-panel light messages

13Status-light legend

Light status State of the product Action

Processing Data

Manual Feed or Continuable Error

Toner Low

Toner Missing

Jam

Paper Mount

Scanner Error

Supply memory error

Fuser error

Alert message Description Recommended action

Door Open

Engine communication error

Install black cartridge

Jam in cartridge area

Jam in output bin

Jam in Tray

Manual feed

Non-HP supply installed

Load paper

No paper pickup

Print failure

Engine error

Control-panel messages

Press OK

Error

41.X.Error

Turn off then on

Turn off then on Laser/scanner assembly error

XX Error 51.0000

Fan error

Genuine HP supply installed

Service error

Device error

Press OK Door open

Specifications

Load tray # Type Size

Cleaning mode OK to start

Load paper

Press OK for available media

Load tray

Load tray 1 Type Size

Manual duplex

Manual feed Type Size

Used cartridge in use

Used cartridge installed

To accept press OK

Print an event log HP LaserJet P2030 Series Printers only

Event-log messages

Print the event log HP LaserJet P2050 Series Printers only

Event log messages

Solve problems

Jams

Paper-handling problems

Product is jammed.1 Cause Solution

Common causes of jams

Clear jams

Jam locations

Internal areas Print-cartridge area and paper path

Enww

Duplex paper path HP LaserJet P2050 Series Printers only

Enww

Enww

Input trays Tray

Tray

Enww

Tray 3 HP LaserJet P2050 Series Printers only

Output bins

Enww

Printed page is different from what appeared onscreen

Solve image-quality problems

16Printed page is different from what appeared onscreen

Image defect examples

Light print or faded

Vertical lines

Toner specks

Dropouts

Gray background

Vertical repetitive defects

Toner smear

Loose toner

Misformed characters

Curl or wave

Skew

Wrinkles or creases

Toner scatter outline

Print-quality problems associated with the environment

Solve print-quality problems

Print-quality problems associated with paper

Print-quality problems associated with jams

Solve performance problems

Solve direct-connect problems

Solve connectivity problems

Solve network problems

Secondary service menu structure

Service mode functions

Open the secondary service menu

17Secondary Service menu

Engine test

Engine resets

Restore defaults

Nvram initialization HP LaserJet P2050 Series Printers only

Solve problems

Parts and diagrams

Order parts, accessories, and supplies

Print cartridges

Paper-handling accessories

Part numbers

Memory

Whole unit replacement

Product Model Voltage Description Part number

1Common fasteners

Screws

Example Description Size Part Number

How to use the parts lists and diagrams

How to use the parts lists and diagrams

External covers, panels, and doors

HP LaserJet P2035

2External covers, panels, and doors HP LaserJet P2035

Description Part number Qty

HP LaserJet P2055

3External covers, panels, and doors HP LaserJet P2055

Internal components 1

Hplj 2050 Series only

4Internal components 1

Internal components 2

4Internal components 2

5Internal components 2

Internal components 3

Hplj 2030 Series only Hplj 2050 Series only

6Internal components 3

Internal components 4

6Internal components 4

7Internal components 4

Internal components 5

7Internal components 5

8Internal components 5

Alphabetical parts list

9Alphabetical parts list

Internal components 1

Switch, push SW301 cartridge-door interlock WC4-5171-000CN

10Numerical parts list

Numerical parts list

Part number Description

External covers, panels, and doors HP LaserJet P2035 on

RM1-6445-000CN Reverse-sensor assembly HP LaserJet P2055

Parts and diagrams

Service and support

Hewlett-Packard limited warranty statement

Print cartridge limited warranty statement

End User License Agreement

Transfer

End User License Agreement

Customer self-repair warranty service

Customer support

Ljp2030series

Next-day on-site service

HP maintenance agreements

On-site service agreements

Weekly volume on-site service

Extended warranty

Appendix a Service and support

Specifications

Table B-1Product dimensions and weights

Physical specifications

Electrical specifications

Table B-3Product dimensions and weights

Acoustic emissions

Operating environment

Appendix B Specifications

Regulatory information

FCC regulations

Declaration of conformity

Declaration of conformity

Declaration of Conformity

Laser safety

Safety statements

Canadian DOC regulations

Laser statement for Finland

Luokan 1 laserlaite

Substances Table China

Symbols/Numerics

Cables

Dimm

See also solving

Macintosh

PCL

Enww

Enww

TCP/IP

Enww

Page

CE457-90980* *CE457-90980

![]() CAUTION: Do not use solvents or oils to clean rollers. Instead, rub the roller with

CAUTION: Do not use solvents or oils to clean rollers. Instead, rub the roller with ![]() NOTE: The following table replaces the graphical repetitive defect ruler. You can make your own ruler by using these measurements. For the most accurate results, use a metric ruler.

NOTE: The following table replaces the graphical repetitive defect ruler. You can make your own ruler by using these measurements. For the most accurate results, use a metric ruler.