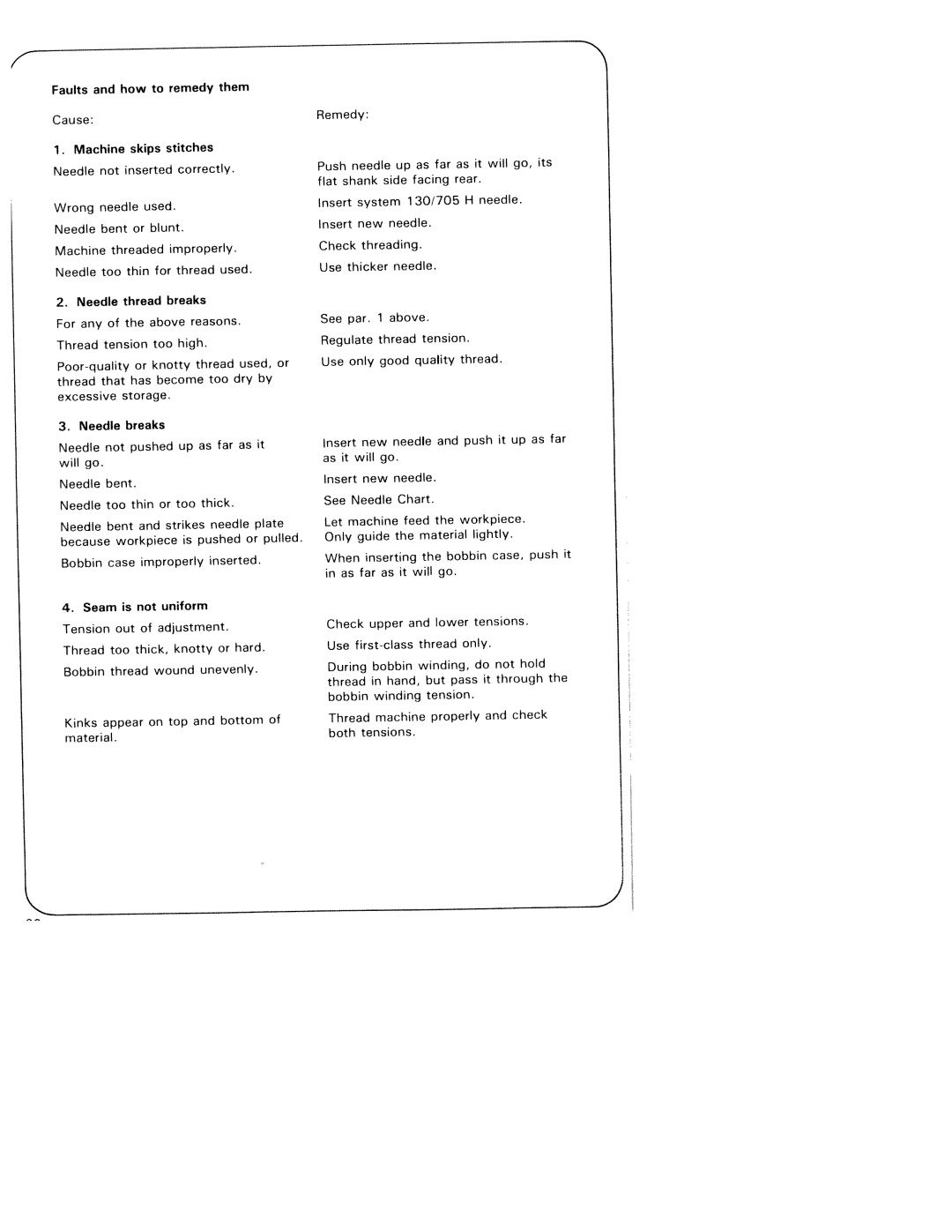

Faults and | how | to remedy | them |

|

| ||||||

Cause: |

|

|

|

|

|

|

|

|

|

| |

1. Machine skips | stitches |

|

|

| |||||||

|

|

|

|

| |||||||

Needle | not | inserted | correctly. |

|

| ||||||

|

|

|

| ||||||||

Wrong | needle | used. |

|

|

|

| |||||

|

|

|

|

|

|

| |||||

Needle | bent | or |

| blunt. |

|

|

| ||||

Machine threaded | improperly. |

|

| ||||||||

|

|

|

|

| |||||||

Needle | too | thin | for | thread | used. |

|

| ||||

2. | Needle | thread | breaks |

|

|

| |||||

|

|

|

|

| |||||||

For | any of | the |

|

|

|

| . |

|

| ||

| above reasons |

|

| ||||||||

Thread | tension | too | high. |

|

|

| |||||

or | knotty thread used, | or | |||||||||

has become too dry | by |

| |||||||||

thread | that |

| |||||||||

excessive storage | . |

|

|

|

| ||||||

|

|

|

|

| |||||||

Remedy: |

|

|

|

|

|

|

|

| ||

Push | needle | up |

| as far | as | it will | go, | its | ||

|

| |||||||||

flat shank | side | facing | rear. |

|

| |||||

Insert | system 130/705 H |

| . |

| ||||||

needle |

| |||||||||

Insert |

|

|

|

| . |

|

|

|

| |

new needle |

|

|

|

| ||||||

Check |

|

|

|

| . |

|

|

|

| |

threading |

|

|

|

| ||||||

Use | thicker |

|

| . |

|

|

|

| ||

needle |

|

|

|

| ||||||

See | par. | 1 | above. |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |

Regulate | thread | tension. |

|

|

| |||||

|

|

|

|

| ||||||

Use | only | good | quality | thread. |

|

| ||||

3. | Needle | breaks |

|

|

|

| ||

Needle | not | pushed | up | as far as | it | |||

will | go. |

|

|

|

|

|

|

|

Needle | bent. |

|

|

|

|

| ||

Needle | too | thin | or | too | thick. |

| ||

Needle | bent and | strikes | needle | plate | ||||

because workpiece | is | pushed or pulled. | ||||||

Bobbin | case improperly | inserted. | ||||||

|

| |||||||

Insert new | needle | and | push | it up | as | far | ||||

|

| |||||||||

as it will go. |

|

|

|

|

|

|

|

| ||

Insert | new | needle | . |

|

|

|

|

|

| |

|

|

|

|

|

|

| ||||

See Needle | Chart. |

|

|

|

|

|

| |||

Let machine feed | the |

|

| . |

|

|

| |||

workpiece |

|

|

| |||||||

Only guide | the | material | lightly. |

|

|

| ||||

|

|

|

|

| ||||||

When | inserting | the bobbin | case, | push | it | |||||

| ||||||||||

in as | far as it will | go. |

|

|

|

|

|

| ||

|

|

|

|

|

|

| ||||

4. | Seam | is | not | uniform |

|

Tension out |

|

|

|

| . |

|

| |

of adjustment |

|

| ||||||

Thread too | thick, | knotty | or | hard. |

| |||

Bobbin | thread | wound | unevenly. |

| ||||

|

|

|

| |||||

Kinks | appear | on | top | and | bottom | of | ||

| ||||||||

material. |

|

|

|

|

|

|

| |

Check | upper and lower |

|

| . |

| |||

tensions |

| |||||||

Use | thread only. |

|

|

| ||||

During | bobbin | winding, | do | not | hold |

| ||

| the | |||||||

thread | in hand, | but pass it | through | |||||

| ||||||||

bobbin winding | tension. |

|

|

|

| |||

|

|

|

|

| ||||

Thread machine | properly and check |

| ||||||

|

|

|

|

| ||||

| . |

|

|

|

|

|

| |

both tensions |

|

|

|

|

|

| ||