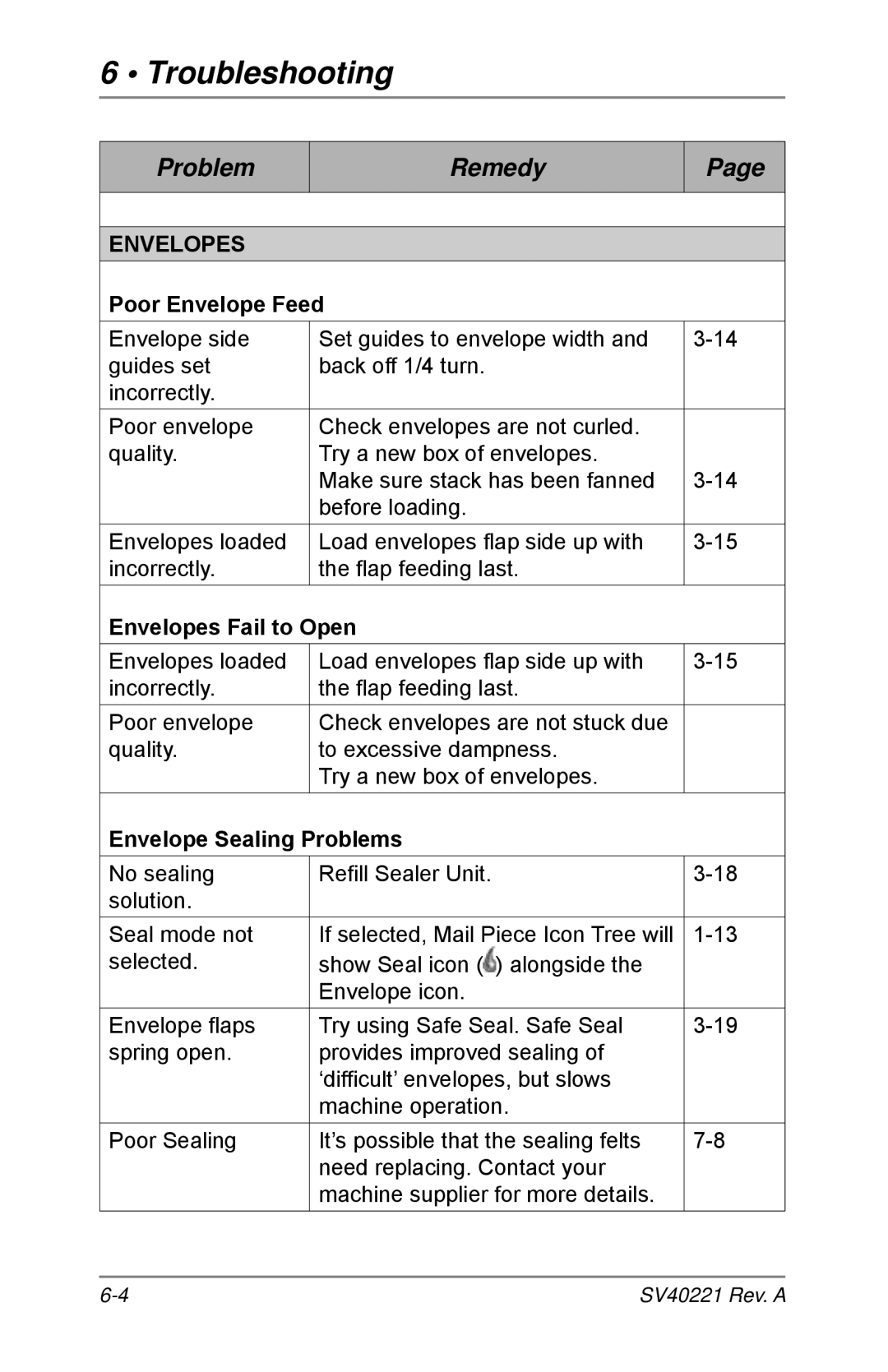

6 • Troubleshooting

Problem

Remedy

Page

ENVELOPES

Poor Envelope Feed

Envelope side | Set guides to envelope width and | |

guides set | back off 1/4 turn. |

|

incorrectly. |

|

|

Poor envelope | Check envelopes are not curled. |

|

quality. | Try a new box of envelopes. |

|

| Make sure stack has been fanned | |

| before loading. |

|

Envelopes loaded | Load envelopes flap side up with | |

incorrectly. | the flap feeding last. |

|

Envelopes Fail to Open |

| |

Envelopes loaded | Load envelopes flap side up with | |

incorrectly. | the flap feeding last. |

|

Poor envelope | Check envelopes are not stuck due |

|

quality. | to excessive dampness. |

|

| Try a new box of envelopes. |

|

Envelope Sealing Problems |

| |

No sealing | Refill Sealer Unit. | |

solution. |

|

|

Seal mode not | If selected, Mail Piece Icon Tree will | |

selected. | show Seal icon ( ) alongside the |

|

| Envelope icon. |

|

Envelope flaps | Try using Safe Seal. Safe Seal | |

spring open. | provides improved sealing of |

|

| ‘difficult’ envelopes, but slows |

|

| machine operation. |

|

Poor Sealing | It’s possible that the sealing felts | |

| need replacing. Contact your |

|

| machine supplier for more details. |

|

SV40221 Rev. A |