Midi Tecna System System / LE

S20

Gentile cliente Grazie per averci accordato la Sua fiducia

Villastanza di Parabiago MI Viale della Repubblica

Page

Italiano

Convenzioni tipografiche

MODELLOS24 S26 S27 Midi Tecna System SYSTEM/LE

Descrizione Delle Macchine

Avvertenze Generali

Specifiche funzionali e composizione macchine

S24 S26 S27

Mod. System 3DE H/TS

SYSTEM/LE

Protezioni meccaniche

Dotazione macchine

Sicurezze elettriche

Rumore aereo

Dati Tecnici

Dimensioni e pesi

Midi Tecna System

CD -DE CD-DE-H-HTS

Trasporto

Destinazione D’USO

Controindicazione d’uso

Imballo

Installazione

Allacciamenti da predisporre a cura del cliente

Alimentazione idrica e gas

Operazioni preliminari

Alimentazione elettrica

Allacciamento

Attenzione

Comandi

Messa in Servizio

Strumenti di controllo

Controllo visivo della pressione in caldaia

Controllo visivo della pressione in caldaia e della pompa

Modello S24

Avvio macchina

Modello S26 S27

Modello Midi Tecna System

Modello System LE

Come si prepara il caffè

Come si riscalda una bevanda

Come si prepara il cappuccino escluso DE/H TS

Versioni DE/H TS/LE

Come si prepara il the, camomilla, ecc

Modelli S27-MIDI DE-TECNA DE

Regolazioni E Tarature Dosi

Regolazioni dosatura

Regolazione dosi di acqua calda

Giornaliera

Manutenzione

Settimanale

Modello S24

Modelli S27 Midi DE System DE

Modelli System CD LE

Pulizia filtri e doccette tutte le versioni

Sostituzione acqua in caldaia Mod. Midi Tecna

Addolcitore DP2 DP4

Rigenerazione Modello S24

DP2

DP4

Nota

Versione Macchina CON Riscaldamento Supplementare a GAS

Inconvenienti E Rimedi

Messa Fuori Servizio

Temporanea

Definitiva

Francais

MODELESS24 S26 S27 Midi Tecna System SYSTEM/LE

Symbolique

Description DES Machines

Avertissements DE Caractere General

Spécifications fonctionnelles-composition machines

Légende des symboles

SYSTEM/LE

Protections mécaniques

Equipements des machines

Dispositifs de sécurités électriques

Bruit aérien

Dimensions et poids

Donnees Techniques

CD -DE CD-DE-H-HTS SYSTEM/LE

Transport

Destination D’EMPLOI

Contre-indications d’emploi

Emballage

Installation

Raccordements aux soins du client

Alimentation hrydrique et gaz

Alimentation électrique

Opérations préliminaires

Mise en place

Commandes

Mise EN Service

Voir les instructions correspondantes au point

Instruments de contrôle

Garder le bouton pressé pour remplir la chaudière

Contrôle visuel de la pression dans la chaudière

Modèle S24

Démarrage machine

Modèle S26 S27

Modèle Midi Tecna System

Comment préparer le café

Emploi

Tournant dans le sens des aiguilles d’une montre de

Modèle System LE

Comment réchauffer une boisson

Comment préparer le capuccino

Versions DE/H TS/LE

Comment préparer le thé, la camomille, etc

Modèles S27-MIDI DE-TECNA DE

Reglages ET Calibrages Doses

1. Réglages dosage

2. Réglage doses d’eau chaude

Quotidien

Entretien

Hebdomadaire

Modèles S24

Entretiens périodiques

Remplacement de l’eau de la chaudière Midi Tecna

Adoucisseur DP2 DP4

10.3.3. Régénération

Effectuées par des personnes professionnellement qualifiées

Version Machine Avec Chauffage D’APPOINT AU GAZ

Inconvenients ET Remedes

Mise Hors DE Service

Temporaire

Définitive

Deutsch

Zeichen

Beschreibung DER Maschinen

Allgemeine Anweisungen

Eigenschaften und Zusammensetzung der Maschinen

S24 S26 S27

SYSTEM/LE

Mechanische Schutzvorrichtungen

Maschinenzubehör

Elektrische Sicherheten

Geräuschpegel

Technische Daten

Außenmaße und Gewicht

CD -DE CD-DE-H-HTS SYSTEM/LE1

Unzweckmäßiger Gebrauch

Gebrauch

Verpackung

Kontrolle am Maschinenempfang

Anschlüsse, die durch den Kunden vorgesehen werden müssen

Wasser- und Gasanschluß Abb.5

Vorbereitungsarbeiten

Elektrischer Anschluß

Positionierung

Achtung

Bedienung Abb.8

Inbetriebnahme

Kontrollinstrumente Abb.8

Visuelle Kontrolle des Drucks im Heizkessel

Visuelle Kontrolle des Drucks im Heizkessel und der Pumpe

Modell S24 Abb.9

Inbetriebnahme

Modell S26 S27 Abb.8

Modelle Midi Tecna System Abb.8

Zubereitung von Kaffee

Zubereitung von warmen Getränken Abb.8

Zubereitung von Cappuccino Abb.11 Augeschlossen DE/H TS

Versionen DE/H TS/LE

Zubereitung von Tee, Kamillentee, usw

Modelle S27 Midi DE Tecna DE

Dosiereinstellungen

Einstellung der Heißwasser-Menge

10.1. Tägliche Wartung

Wartung

10.2. Wöchentliche Wartung

Modell S24

Wechsel des Kesselwassers

Periodische Wartung

Wasserenthärter DP2 DP4

Regenerierung

Hinweis

Version DES Automaten MIT Zusätzlicher Gasheizung

13. Störungen UND Abhilfe

Ausser Betrieb Setzen

Zeitweilig

Endgültig

GB English

MODELS24 S26 S27 Midi Tecna System SYSTEM/LE

Symbols

Description

General Safety Rules

Specifications and composition

S24 S26 S27

SYSTEM/LE

Machine equipment

Electric safety devices

Mechanical protective devices

Aerial noise

Dimensions and weights

Technical Data

Gross weight kg

Width mm

Packaging

Precautionary measures

Inspection on receipt

User must not

Water and gas supply

Connections to be made by the user

Electricity supply

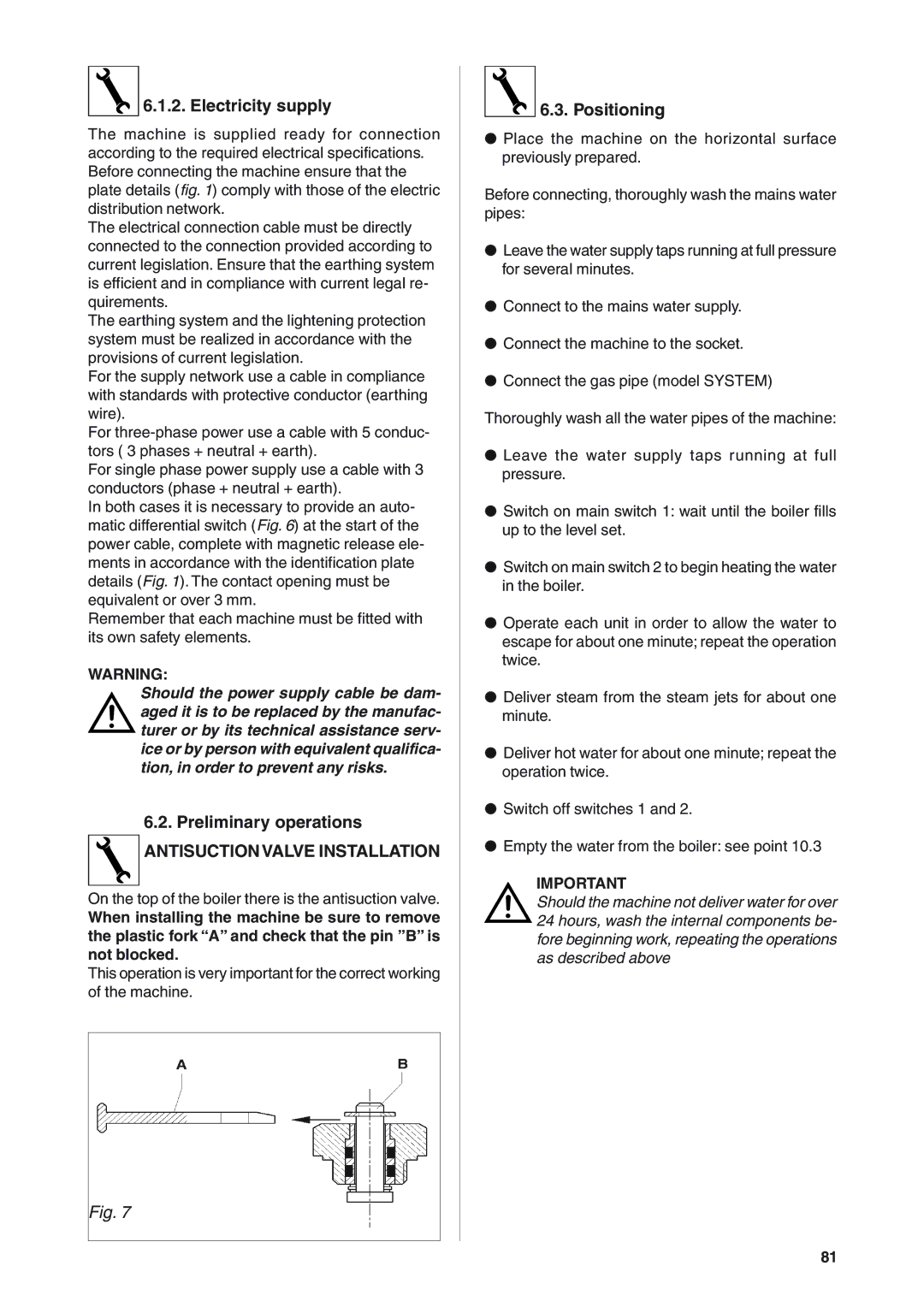

Preliminary operations

Positioning

Controls

Setting UP

Control instruments

Model S24

Starting up

Model S26 S27

Model Midi Tecna System

Model System LE

Preparing coffee

Heating a beverage

Preparing cappuccino excluding DE/H TS

Version De/H TS/LE

Preparing tea, camomile, etc

Adjusting the dose

Adjusting the quantity of hot water

Models S27 Midi DE Tecna DE

Daily

Maintenance

Weekly

Models S24 S26 Midi CD

Renewal of water in the boiler Models Midi Tecna

Cleaning the filters and delivery heads

Models System CD -LE

Models S27 Midi DE Sysetm DE

Softener DP2 DP4

Regeneration

Machines with Alternative GAS Heater Version

Stopping the Machine

Problems and Remedies

Temporary stop

Definitive stop

Esquemas Electricos

Simbología

MODELOSS24 S26 S27 Midi Tecna System SYSTEM/LE

Descripción DE LAS Maquinas

Advertencias Generales

Especificaciones funcionales y composición de las máquinas

Explicación de la simbología

SYSTEM/LE

Protecciones mecánicas

Dotaciones de las máquinas

Seguridades eléctricas

Ruido aéreo

Dimensiones y pesos

Datos Técnicos

Tecna System

Transporte

Destinación DE USO

Contraindicaciones de uso

Embalaje

Enlaces que debe predisponer el cliente

Instalación

Alimentación de agua y gasFig.6

102

Operaciones preliminares

Alimentación eléctrica

Instalación

Atención

Puesta EN Servicio

Mandos

104

105

Instrumentos de control

Puesta en marcha de la máquina

Cómo se prepara el café

Modelos System LE, Fig

107

Cómo se prepara una bebida

Cómo se prepara el capuchino Excluido mod. DE/H TS

Versiones DE/H TS/LE

Cómo se preparan té, manzanilla, etc

Regulación dosis de agua

Regulación dosificación

Cuidado

109

Diaria

Manutención

Semanal

Modelo S24

Modelos System CD

Modelos System CD -LE

Sustitución del agua de la Caldera

Aluminio O DE Hierro

Regeneración

Eliminador de caliza DP2 DP4

112

113

Version Maquina CON Calentamiento Suplementario POR GAS

Inconvenientes Y Soluciones

Puesta Fuera DE Servicio

Temporánea

114

115

116

S24

117

S26

118

S27

119

120

121

122

Tecna

123

124

Midi

125

126

127

Propriété réservée

128