JW-21MN

JW-21MN

Safety Precautions

Installation

Wiring Compel

Use

Maintenance Prohibit

ME-NET Module JW-21MN

Table of contents

Setting of Switches and Parameter 11-1 to

Errors and Countermeasures 12-1 to

Description for Computer Link Operation 10-1 to

Support Tools 14-1 to Specifications 15-1 to

13-1

Appendix 16-1 to

Features and Functions

Data link function

Computer link function

Wiring

Installation

Connector

Treatment

Maintenance

Static electricity

Allocation of relay number

JW20H JW-21MN JW-21MN JW30H

System Configuration

Front view

Name and Function of Each Part

Installation

Installation procedure

Remarks

Name Model Maker

Processing of Cables

Processing cable end

Fine adjustment of blade cutting depth

Cutting of coating, external conductor, and insulator

Removal of coating, external conductor, and insulator

Processing of cable end

Display of blade setting

Connector ME-GP-01 Processing procedure Insert a sleeve

Connector crimping procedure

Required tools Hand-held crimping tool

Crimping contact

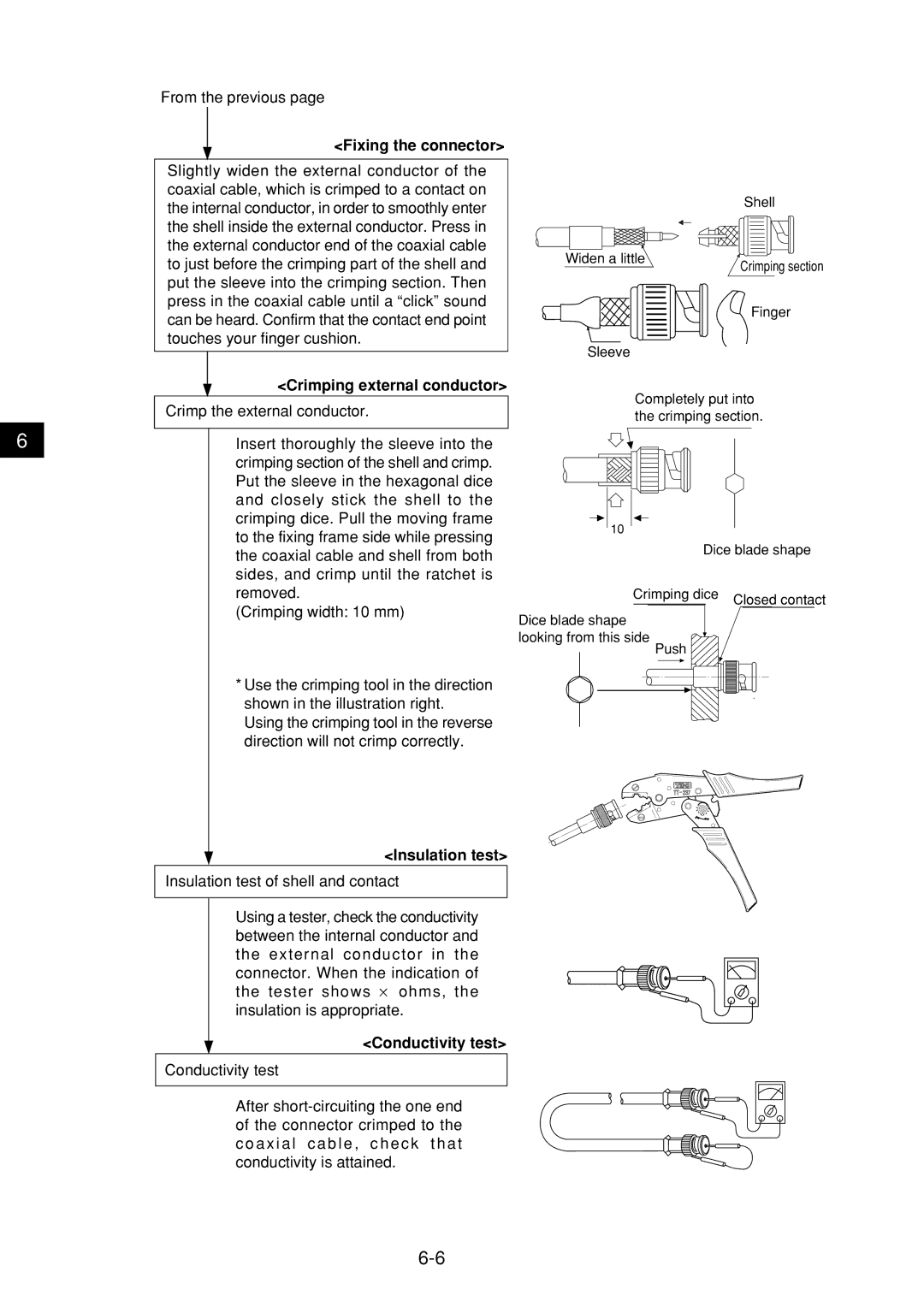

Fixing the connector

Insulation test

Conductivity test

Wiring Method

Cable trunk and branch lines

Relaying of trunk cables

Cable wiring procedure in control panel

Page

Branch connector

Waterproof and insulation processing of connectors

Straight connector

Remarks

Check after wiring

Wiring of cables at outside control panels

Station number of the additional station

Branching method

Reason

Memory Address on the ME-NET

Memory address for data links

Memory address map against JW20/JW20H

JW30H address ME-NET address

Memory address map against JW30H

JW20/20H ME-NET address Capacity

Memory addresses for computer links

JW30H address ME-NET address Capacity Remarks

Communication method

Description for Data Link Operation

Data link Standard function

Relay link

Setting item Set location

Data link Save memory function

Register link

Required transmission time

Required transmission time and communication delay time

Communication delay time

An example of synchronized transfer by OUT instruction

Data transmission between master PC and slave PC

Multiple installation of the JW-21MN

Expansion of network

Case of mounting 4 sets of JW-21MN

Hierarchical link

Optional commands

Basic commands

Description for Computer Link Operation

Computer link function

10-2

Basic commands

Optional commands

10-3

Communication format, basic pattern

Read free memory size

Write mode assignment None Communication format

Monitor TMR, CNT, and MD

10-4

Reading PC mode

Setting PC mode

10-5

Reading system memory

Writing system memory

10-6

Write mode assignment 1 or Communication format

Setting date

Reading date

10-7

Setting time

Reading time

10-8

Correct clock time

Monitor step status JW20/JW20H only

10-9

Read the optional parameters

Write mode assignment

Set the optional parameters

10-10

Read the special I/O parameters

Set the special I/O parameters

10-11

Release the secret function, register password JW30H only

Set the secret function JW30H only

10-12

10-13

Check the secret function JW30H only

10-14

Response on error

Setting of Switches and Parameter

Operation procedure

11-1

Mode switch Mode

Switch setting of master station and slave station

Module No. switch Unit no

11-2

Termination resistance switch LT

Station number switch STA no

11-3

Reference Need for the termination resistance

11-4

Shield ground switch LG

Setting contents of master station parameters

Value H

11-6

Parameter for setting in slave station

Parameter for setting in master station

Communication area map

11-7

11-8

11-9

+ h

Example for setting

11-10

Maser station Slave station Standard Save memory

11-11

When master station PC is JW20/JW20H

11-12

When master station PC is JW30H

11-13

Setting procedure

11-14

Example Stop operation of data link HEX hexadecimal, byte

Stop operation of data link HEX hexadecimal, byte

Data link function setting HEX hexadecimal, byte

Set number of connecting stations DCM decimal, byte

11-15

Set top address of register link area on the master station

11-16

Set in parameter addresses 005000 to

11-17

11-18

Set connection status of slave station Bit pattern, byte

11-19

11-20

PC operation

11-21

Setting item

Contents

11-22

When PC is JW20/JW20H

Setting range of flag area

When PC is JW30H

11-23

11-24

11-25

Turn on the power of slave station PC Connect support tools

11-26

11-27

11-28

Indication lamps

Errors and Countermeasures

12-1

Details Measure

Remark

Flag

12-3

Case of a master station

Communication monitor flag

Operation condition monitor flag

12-4

Case of slave station 01 to

12-5

Monitor operation condition by each station PC

12-6

Storage of error code

System memory #160 to 167 self diagnosis error code

System memory #170 to 177 option module error code

System memory #150 monitor error switch number

12-7

12-8

Error history

13-1

Replacement of the JW-21MN

Support Tools

Record and load by ladder software JW-92SP, JW-50SP Record

14-1

14-2

Load

Load to the personal computer

Stop operation of the JW-21MN

General specifications

Specifications

Communication specifications

Specification

Standard function Specifications

Data link specifications

Save memory function Specifications

15-2

Computer link specifications

Outside dimensional drawings

15-3

Maintenance and check

Appendix

16-1

Recovery method at communication errors

Check flow chart

16-2

16-3

Check cable/connector

Cause Countermeasure

16-4

007764 to

16-5

Check items of cables and connectors

Switches required check in the JW-21MN

16-6

Other cases

Identify the error station

Check the errors timing

When identification of the cause is difficult

16-7

Table of parameter memory

16-8

Master station

16-9

Set contents Setting method value, example

16-10

16-11

Slave station 01 to

16-12

16-13

Special functions unique to the JW-21MN

Remote programming and remote monitor

Support tool Opposite module Connection module

Function Standard network connection

16-14

Expansion network connection

Operation example

16-15

Network setting

Parameter setting by remote function

When used with a computer link

16-16

Alphabetical Index

Operation procedure

Waterproof and insulation processing of connectors