May

Page

Chiller System Design and Control

Preface

Contents

100

Primary System Components

Chiller

Primary System Components

Chiller evaporator

Effect of chilled-water temperature

Effect of chilled-water flow rate and variation

Effect of condenser-water temperature

Water-cooled condenser

Effect of condenser-water flow rate

Air-cooled versus water-cooled condensers

Maintenance

Air-cooled condenser

Packaged or Split System?

Low-ambient operation

Energy efficiency

Loads

Air-cooled or water-cooled efficiency

Three-way valve load control

Two-way valve load control

Variable-speed pump load control

Face-and-bypass dampers

Chilled-Water Distribution System

Chilled-water pump

Distribution piping

Pump per chiller

Manifolded pumps

Pumping arrangements

Constant flow system

Primary-secondary system

Condenser-Water System

Cooling tower

Variable-primary system

Effect of ambient conditions on cooling tower performance

Condenser-water pumping arrangements

Effect of load on cooling tower performance

Single tower per chiller

Unit-Level Controls

Chiller control

Recommended chiller-monitoring points per Ashrae Standard

Centrifugal chiller capacity control

Centrifugal chiller with AFD

AFD on both chillers

Application Considerations

Small Chilled-Water Systems 1-2 chillers

Application Considerations Constant flow

Variable flow

Condensing method

Parallel or series

Application Considerations

Number of chillers

Part load system operation

Mid-Sized Chilled-Water Systems Chillers

Managing control complexity

Preferential vs. equalized loading and run-time

Large chilled-water system schematic

Large Chilled-Water Systems + Chillers, District Cooling

Power

Pipe size

Water

Chiller Plant System Performance

Chiller performance testing

Limitations of field performance testing

Controls

SYS-APM001-EN

SYS-APM001-EN

System Design Options

Guidance for Chilled- and Condenser-Water Flow Rates

Chilled-Water Temperatures

Standard rating temperatures

System Design Options

Condenser-Water Temperatures

Chilled- and Condenser-Water Flow Rates

Standard rating flow conditions

System Design Options Selecting flow rates

DP2/DP1 = Flow2/Flow11.85

Low-flow conditions for cooling tower Base Case Low Flow

Total system power Component Power kW Base Case Low Flow

System summary at full load

Coil response to decreased entering water temperature

Chilled water system performance at part load

Smaller tower

Entering fluid temperature, F C

Cooling-tower options with low flow

System design

ΔT2 = 99.1 78 = 21.1F or 37.3 25.6 = 11.7C

Same tower, smaller approach

Same tower, larger chiller

Same tower, smaller approach Present Smaller Approach

Retrofit opportunities

Retrofit capacity changes Larger Present Chiller Same tower

Cost Implications

Misconceptions about Low-Flow Rates

Misconception 1-Low flow is only good for long piping runs

KWh

SYS-APM001-EN

System Configurations

Parallel Chillers

System Configurations

Parallel chillers with separate, dedicated chiller pumps

Series Chillers

Series chillers

Primary-Secondary Decoupled Systems

Hydraulic decoupling

Check valves

System Configurations Production

Production loop

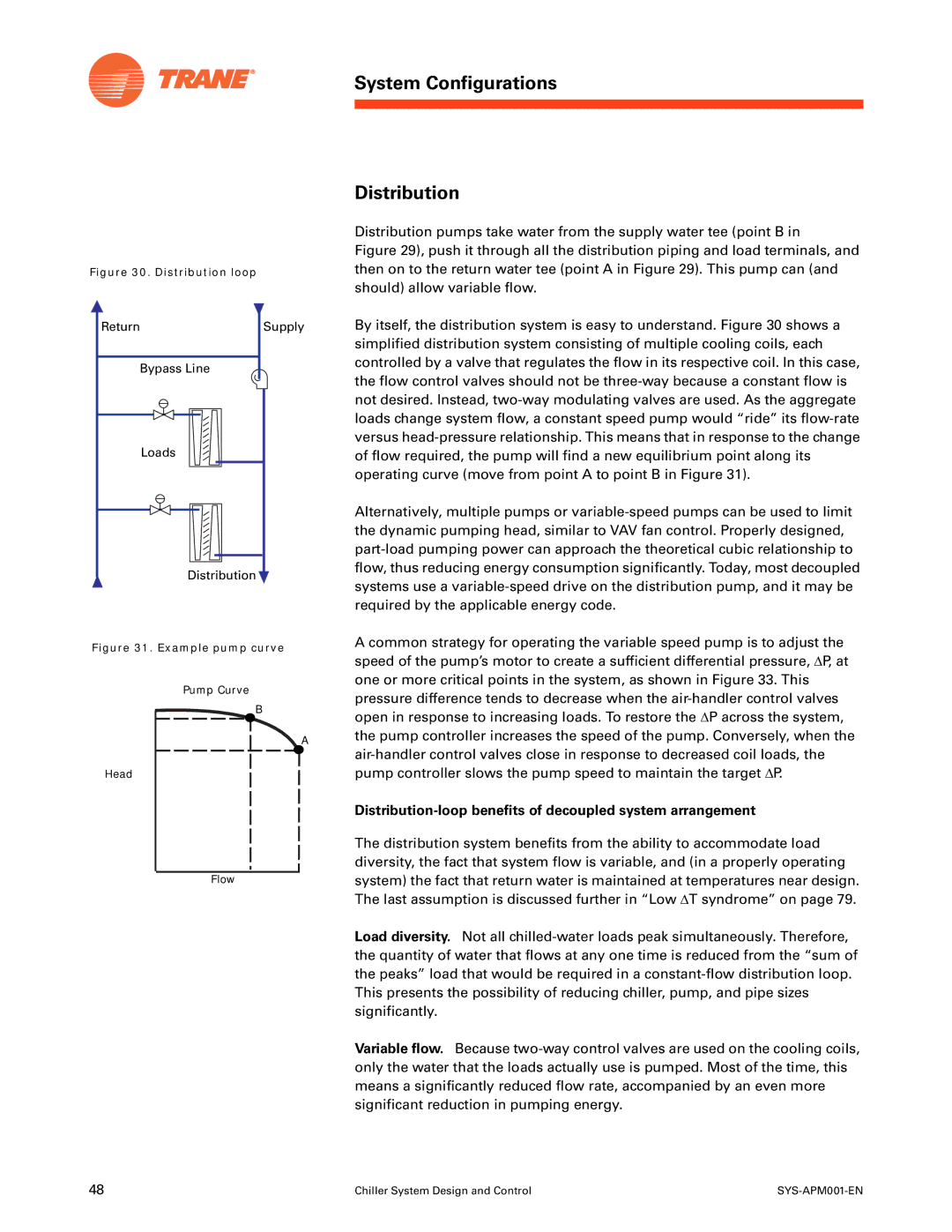

System Configurations Distribution

Distribution-loop benefits of decoupled system arrangement

Common

Campus

Tertiary or distributed

Decoupled system-principle of operation

Tertiary pumping arrangement

Temperature-sensing

Flow-based control

Flow-sensing

Multiple chilled-water plants on a distribution loop

Adding a chiller

Subtracting a chiller

Pump control in a double-ended decoupled system

Double-ended decoupled system

Chiller sequencing in a double-ended decoupled system

Variable-Primary-Flow Systems

Other plant designs

Advantages of variable primary flow

Operational savings of VPF designs

Chiller selection requirements

Dispelling a common misconception

Flow, ft.water Flow rate

Managing transient water flows

Flow-rate changes that result from isolation-valve operation

System Configurations

System design and control requirements

Effect of dissimilar evaporator pressure drops

Accurate flow measurement

Chiller sequencing in VPF systems

Bypass flow control

Adding a chiller in a VPF system

Flow-rate-fluctuation examples

Subtracting a chiller in a VPF system

Sequencing based on load

Other VPF control considerations

Select slow-acting valves to control the airside coils

Plant configuration

Consider a series arrangement for small VPF applications

Guidelines for a successful VPF system

Chiller selection

Chiller sequencing

Plant configuration

Bypass flow

Airside control

Condenser Free Cooling or Water Economizer

Heat Recovery

Chilled-Water System Variations

Plate-and-frame heat exchanger

Chilled-Water System Variations

Refrigerant migration

Refrigerant migration chiller in free-cooling mode

Well, river, or lake water

Preferential Loading

Preferential loading parallel arrangement

Preferential loading sidestream arrangement

Sidestream plate-and-frame heat exchanger

Sidestream with alternative fuels or absorption

Chilled-Water System Variations

Preferential loading series arrangement

Sidestream system control

Series-Counterflow Application

Series-series counterflow

Unequal Chiller Sizing

Evaporators

Condensers

System Issues and Challenges

Low ΔT Syndrome

Amount of Fluid in the Loop

System response to changing conditions

System Issues and Challenges

Chiller response to changing conditions

Example

Contingency

Minimum capacity required

Type and size of chiller

Water and electrical connections

System Issues and Challenges Location of equipment

Alternative Energy Sources

Ancillary equipment

Plant Expansion

Alternative fuel

Thermal storage

Retrofit Opportunities

Applications Outside the Chiller’s Range

Flow rate out of range

System Issues and Challenges Temperatures out of range

Precise temperature control

Precise temperature control, multiple chillers

Chilled-Water System Control

Chilled water reset-raising and lowering

System Controls

Chilled-water pump control

Critical valve reset pump pressure optimization

System Controls

Number of chillers to operate

VFDs and centrifugal chillers performance at 90% load

Condenser-Water System Control

Minimum refrigerant pressure differential

Chillers Difference

Condenser-water temperature control

Cooling-tower-fan control

Chiller-tower energy balance

Chiller-tower energy consumption

System Controls Variable condenser water flow

Chiller-tower-pump balance

Decoupled condenser-water system

Effect of chiller load on water pumps and cooling tower fans

CDWP-2

Failure Recovery

Failure recovery

Conclusion

Glossary

Glossary

Pumps system

Glossary

References

Plant. Idea 88th Annual Conference Proceedings 1997

References

Engineering July

102

Index

Ashrae

Index

105

106

Page

Trane