4. Sample program

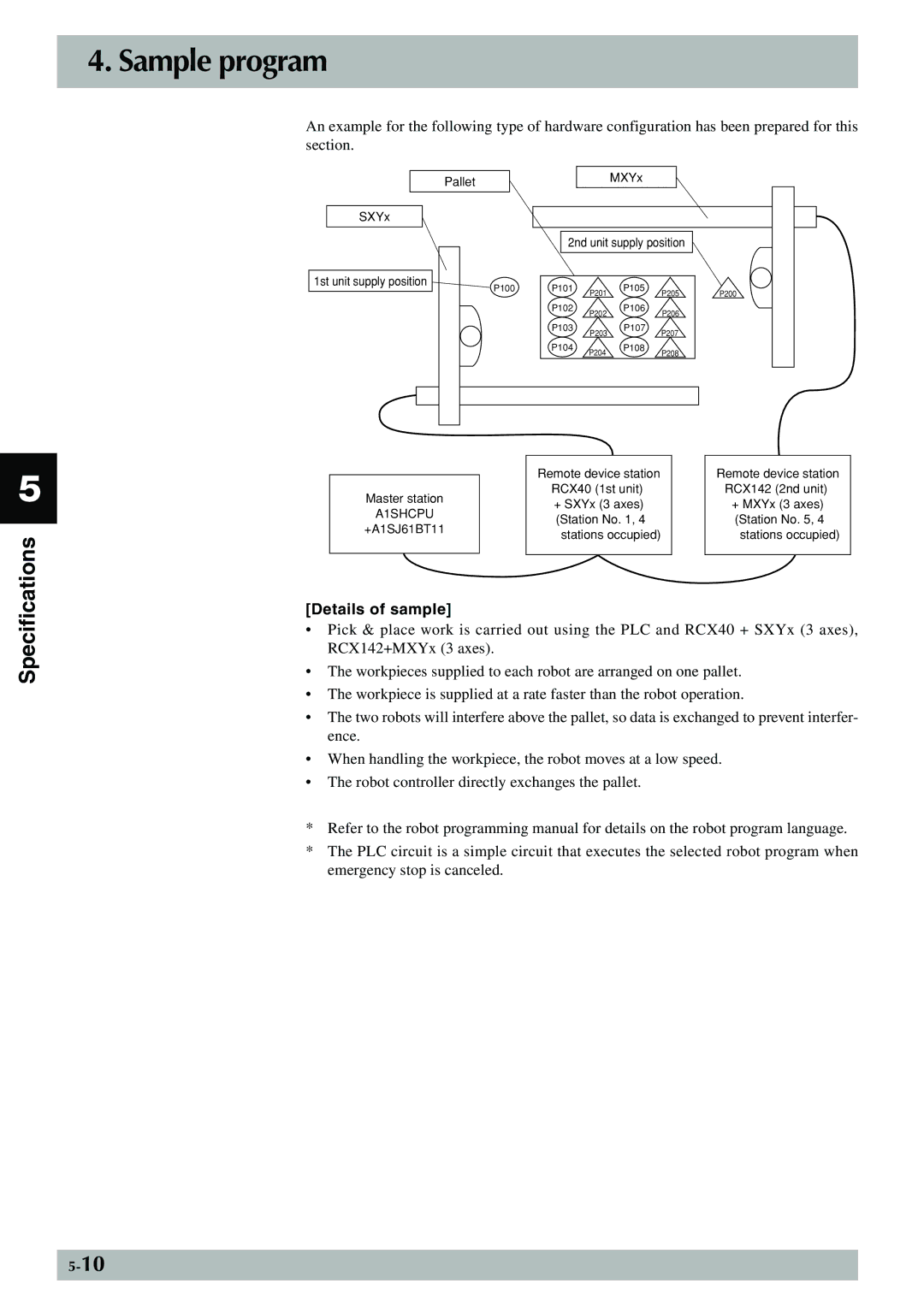

An example for the following type of hardware configuration has been prepared for this

section. |

|

|

|

|

|

|

| Pallet |

|

| MXYx |

|

|

|

|

|

|

|

| |

SXYx |

|

|

|

|

|

|

|

| 2nd unit supply position |

| |||

1st unit supply position | P100 | P101 | P201 | P105 |

|

|

| P205 | P200 | ||||

|

|

|

| |||

|

| P102 | P202 | P106 | P206 |

|

|

|

|

|

| ||

|

| P103 | P203 | P107 | P207 |

|

|

|

|

|

| ||

|

| P104 | P204 | P108 | P208 |

|

|

|

|

|

| ||

5

Specifications

|

| Remote device station |

| Remote device station |

Master station |

| RCX40 (1st unit) |

| RCX142 (2nd unit) |

| + SXYx (3 axes) |

| + MXYx (3 axes) | |

A1SHCPU |

|

| ||

| (Station No. 1, 4 |

| (Station No. 5, 4 | |

+A1SJ61BT11 |

|

| ||

| stations occupied) |

| stations occupied) | |

|

|

| ||

|

|

|

|

|

[Details of sample]

•Pick & place work is carried out using the PLC and RCX40 + SXYx (3 axes), RCX142+MXYx (3 axes).

•The workpieces supplied to each robot are arranged on one pallet.

•The workpiece is supplied at a rate faster than the robot operation.

•The two robots will interfere above the pallet, so data is exchanged to prevent interfer- ence.

•When handling the workpiece, the robot moves at a low speed.

•The robot controller directly exchanges the pallet.

*Refer to the robot programming manual for details on the robot program language.

*The PLC circuit is a simple circuit that executes the selected robot program when emergency stop is canceled.