100

Maintenance

Fault Finding

Fault Finding

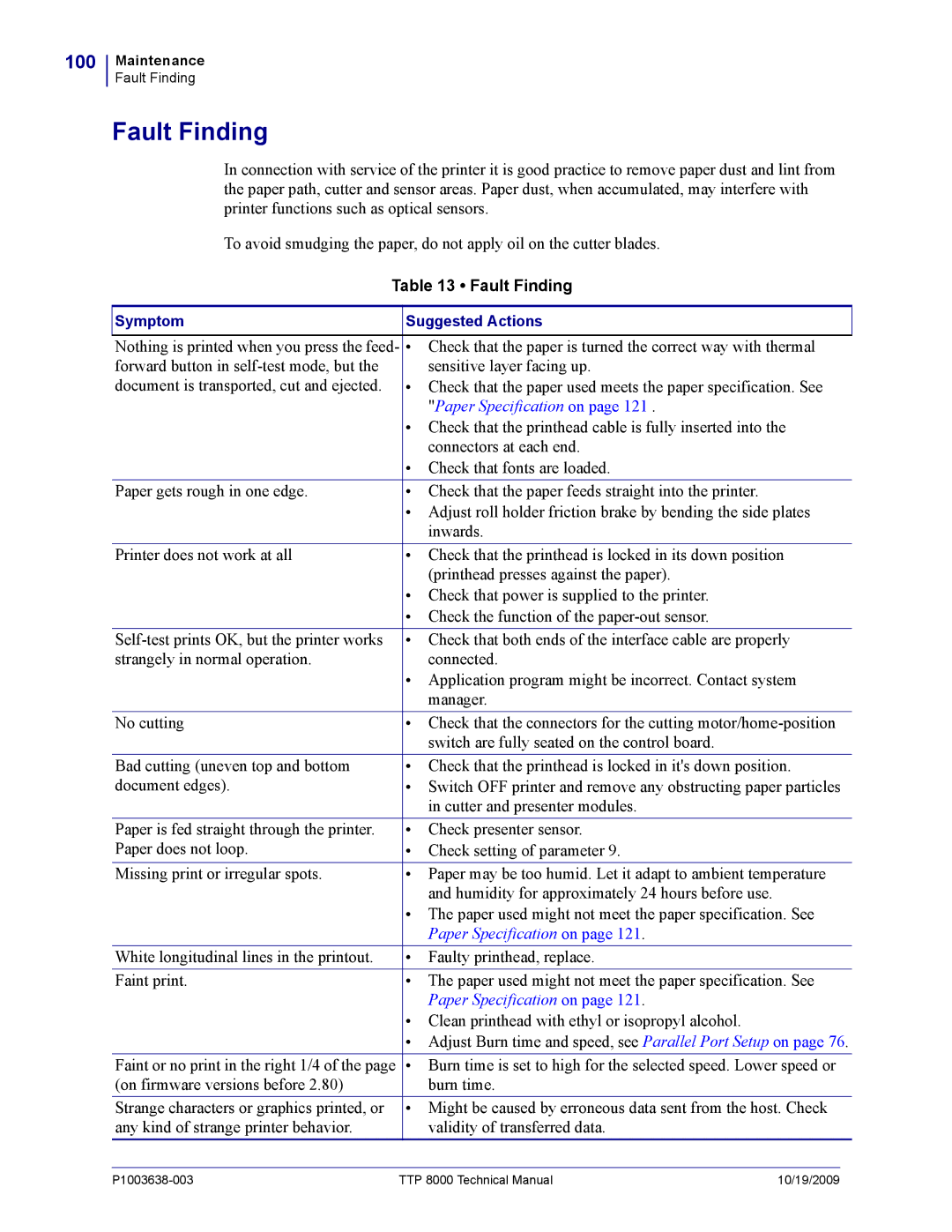

In connection with service of the printer it is good practice to remove paper dust and lint from the paper path, cutter and sensor areas. Paper dust, when accumulated, may interfere with printer functions such as optical sensors.

To avoid smudging the paper, do not apply oil on the cutter blades.

Table 13 • Fault Finding

Symptom | Suggested Actions |

| ||

Nothing is printed when you press the feed- | • | Check that the paper is turned the correct way with thermal | ||

forward button in |

| sensitive layer facing up. | ||

document is transported, cut and ejected. | • | Check that the paper used meets the paper specification. See | ||

|

| "Paper Specification on page 121 . | ||

| • | Check that the printhead cable is fully inserted into the | ||

|

| connectors at each end. | ||

| • | Check that fonts are loaded. | ||

Paper gets rough in one edge. | • | Check that the paper feeds straight into the printer. |

| |

| • | Adjust roll holder friction brake by bending the side plates | ||

|

| inwards. | ||

Printer does not work at all | • | Check that the printhead is locked in its down position |

| |

|

| (printhead presses against the paper). | ||

| • | Check that power is supplied to the printer. | ||

| • | Check the function of the | ||

• | Check that both ends of the interface cable are properly |

| ||

strangely in normal operation. |

| connected. | ||

| • | Application program might be incorrect. Contact system | ||

|

| manager. | ||

No cutting | • | Check that the connectors for the cutting |

| |

|

| switch are fully seated on the control board. | ||

Bad cutting (uneven top and bottom | • | Check that the printhead is locked in it's down position. |

| |

document edges). | • | Switch OFF printer and remove any obstructing paper particles | ||

|

| in cutter and presenter modules. | ||

Paper is fed straight through the printer. | • | Check presenter sensor. |

| |

Paper does not loop. | • | Check setting of parameter 9. | ||

Missing print or irregular spots. | • | Paper may be too humid. Let it adapt to ambient temperature |

| |

|

| and humidity for approximately 24 hours before use. | ||

| • | The paper used might not meet the paper specification. See | ||

|

| Paper Specification on page 121. | ||

White longitudinal lines in the printout. | • | Faulty printhead, replace. |

| |

Faint print. | • | The paper used might not meet the paper specification. See |

| |

|

| Paper Specification on page 121. | ||

| • | Clean printhead with ethyl or isopropyl alcohol. | ||

| • | Adjust Burn time and speed, see Parallel Port Setup on page 76. | ||

Faint or no print in the right 1/4 of the page | • | Burn time is set to high for the selected speed. Lower speed or |

| |

(on firmware versions before 2.80) |

| burn time. | ||

Strange characters or graphics printed, or | • | Might be caused by erroneous data sent from the host. Check |

| |

any kind of strange printer behavior. |

| validity of transferred data. |

| |

| TTP 8000 Technical Manual | 10/19/2009 |