![]() WARNING To avoid electric shock and electrical fires, never use an extension cord that is damaged or does not meet the following requirements:

WARNING To avoid electric shock and electrical fires, never use an extension cord that is damaged or does not meet the following requirements:

•The cord has a

•The cord is rated as “W” or

•The cord has sufficient wire thickness (16 AWG below 50′/14 AWG

![]() WARNING To reduce risk of electric shock, keep all electrical connections dry and off the ground. Do not touch plug with wet hands. Test the Ground Fault Circuit Interrupter (GFCI) provided with the electric cord to insure it is operating correctly. When test button is pushed in, the indicator light should go off. Reactivate by pushing the reset button in. If indicator light goes on, the machine is ready to use. If the GFCI does not function correctly, do not use the machine.

WARNING To reduce risk of electric shock, keep all electrical connections dry and off the ground. Do not touch plug with wet hands. Test the Ground Fault Circuit Interrupter (GFCI) provided with the electric cord to insure it is operating correctly. When test button is pushed in, the indicator light should go off. Reactivate by pushing the reset button in. If indicator light goes on, the machine is ready to use. If the GFCI does not function correctly, do not use the machine.

Operating Instructions

![]() WARNING

WARNING

Wear gloves provided with machine. Never grasp a rotating cable with a rag or loose fitting cloth glove that may become wrapped around the cable, caus- ing serious injury.

Always wear eye protection to protect your eyes against dirt and other foreign objects. Wear rubber soled,

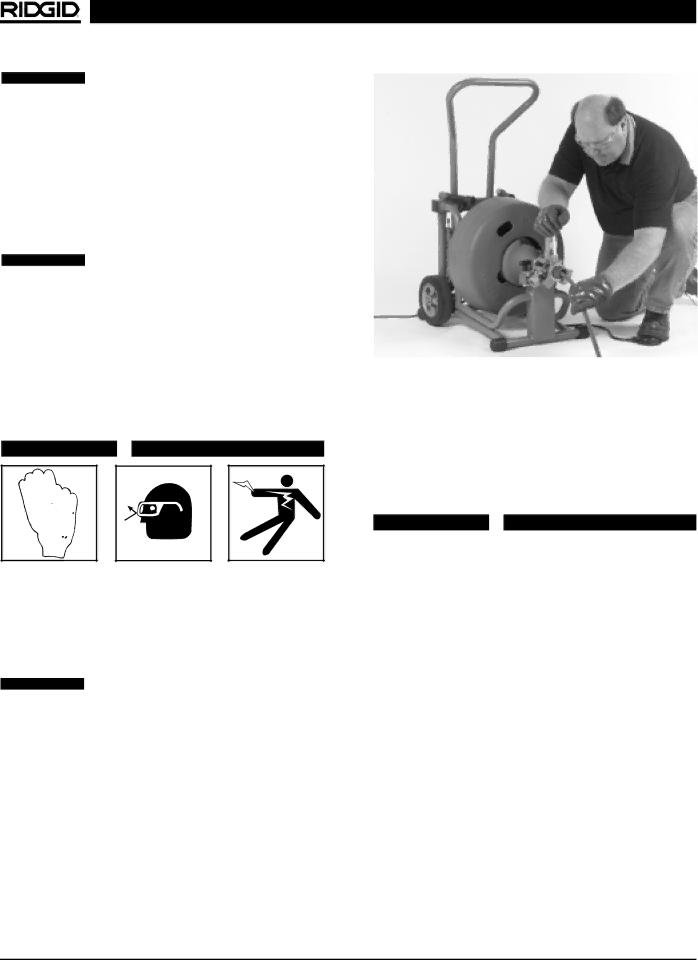

![]() WARNING Always assume the correct operating pos- ture in order to maintain proper balance (Figure 8). Should an unexpected situation arise, this posture provides you with the opportunity to safely keep control of the machine and cable.

WARNING Always assume the correct operating pos- ture in order to maintain proper balance (Figure 8). Should an unexpected situation arise, this posture provides you with the opportunity to safely keep control of the machine and cable.

•Be sure you can quickly remove your foot from the foot switch.

•Hand must be on the cable to control its twisting ac- tion when it hits an obstruction.

•Keep hands away from rotating drum and guide tube. Do not reach into drum unless machine is unplugged.

1.Loosen the feed knob to ensure auto feed is not en- gaged. Manually pull a sufficient length of cable out of the drum and manually push the tool and cable into the sewer inlet.

Figure 8 – Proper Operating Position

2.Move FOR/OFF/REV switch into FOR (forward) po- sition. Do not step on the air foot switch pedal at this time.

3.To use auto feed, turn feed knob down until top bear- ing makes contact with the cable, then turn one full additional turn. Do not

![]() WARNING

WARNING

Before starting machine, operator’s gloved hand must be on the cable.

4.Exert sufficient downward pressure on cable to keep it in sewer line while depressing air foot switch pedal to start cable rotating.

5.Move the feed lever in the opposite direction of the ro- tating drum to advance the cable (Figure 9). The rate at which the cable is fed (0 – 28′ per minute) into the sewer is controlled by the position of the feed lever away from neutral (vertical) position. The further from vertical, the faster the feed rate. Always keep one hand on the cable to feel tension.

6.Continue to feed the cable into the line until resistance or obstruction is encountered. This condition will gen- erally become apparent to the operator as the motor will “lug” down and/or the cable will have a tendency to twist sideways in the operator’s hands.

If the cable shows signs that the cutter has stopped ro- tating, fully reverse feed lever (move handle in the same direction of the drum rotation) to back the cutter away and to relieve the load. Gradually feed the cable into the obstruction, allowing cutter to advance slowly. Occasionally move auto feed lever to neutral

8 | Ridge Tool Company |