Loading The Machine On Vehicle

Loading Wheel

Optional loading wheel swivels up and down. Raise wheel for loading, lower wheel while transporting or op- erating machine.

With loading wheel raised, tip machine backwards and rest handle or loading wheel on truck bed. Lift up on front of machine and slide onto truck.

![]() WARNING Use proper lifting technique – lift with your legs, not your back!!

WARNING Use proper lifting technique – lift with your legs, not your back!!

NOTE! Take care not to damage electrical cord or air foot switch hose.

Lifting Hook

Optional lifting hook can be used to raise and lower the machine into a truck using a hoist. The Machine must be raised by hooking through the hole in the lifting hook.

![]() WARNING Lifting the machine by the handle or any other part of the machine may result in the machine tipping and/or the part failing. This could result in the machine falling causing serious injury.

WARNING Lifting the machine by the handle or any other part of the machine may result in the machine tipping and/or the part failing. This could result in the machine falling causing serious injury.

NOTE! Take care not to damage electrical cord or air foot switch hose.

Draining the Drum

Water can be drained from the drum by removing the screw plug located in the rear of the drum (Figure 10) and resting the machine on its back as seen in Figure 11. Be sure the screw drain plug is replaced before transporting the machine.

Figure 10 – Drum Drain Hole

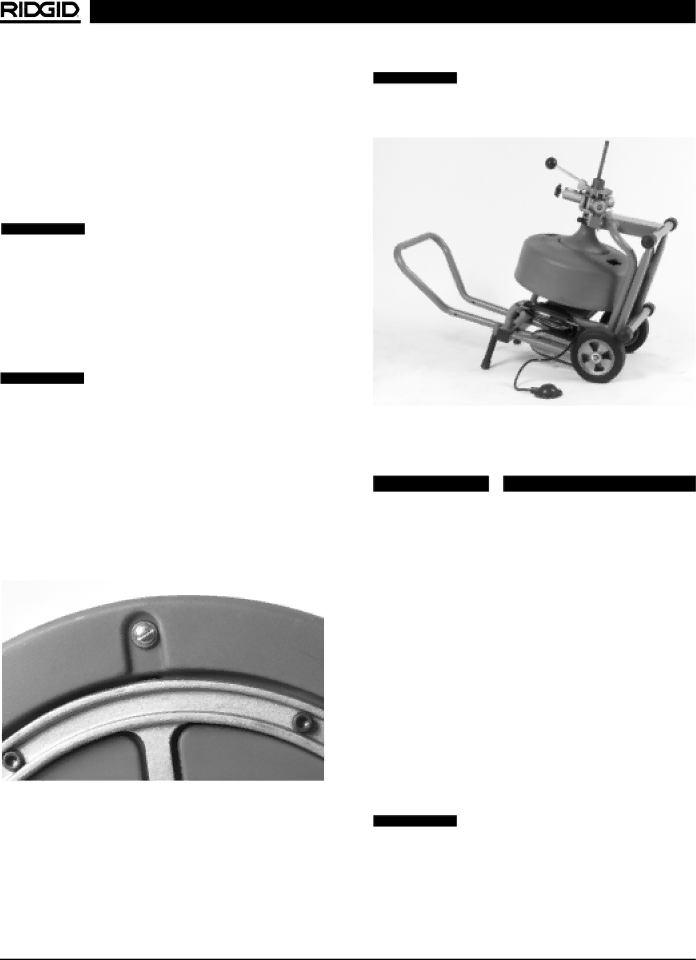

Operating Machine In Reclined Position

The

![]() WARNING If sewer inlet is greater than 3′ from the front off the machine, the cable will have a greater ten- dency to twist or kink. Use a front guide tube or properly support exposed cable.

WARNING If sewer inlet is greater than 3′ from the front off the machine, the cable will have a greater ten- dency to twist or kink. Use a front guide tube or properly support exposed cable.

Figure 11 – Machine In Reclined Position

Drum Assembly Removal & Installation

![]() WARNING

WARNING

Make sure FOR/OFF/REV SWITCH is in OFF position and machine is unplugged from power source.

Drum Removal

1.Set kickstand in the operating position to keep the ma- chine from moving.

2.Loosen the top autofeed knob to make sure the top bearing is not in contact with the cable and remove the cutter.

3.Loosen the two

4.The drum assembly can be removed by grasping the drum via the center hole on the drum front and by lifting and sliding the shaft of the assembly out of the gear box.

![]() WARNING Use proper lifting technique – lift with your legs, not your back!!

WARNING Use proper lifting technique – lift with your legs, not your back!!

Drum Installation

1.Set the kickstand to keep machine from moving.

2.Grasp the drum assembly via the center hole on the drum front and lift the assembly onto the frame. Slide

10 | Ridge Tool Company |